POWDER COATING

AGENDA

o BASIC

o PROCESS FLOW

o COMMON TEST

o TYPES OF DEFECTS

o CAUSES

o PREVENTION

BASIC

🔹 What is Powder Coating?

Powder coating is a dry finishing process where a finely ground mixture of pigments and resins (powder)

is sprayed onto a metal surface using an electrostatic gun and then cured under heat to form a protective and

decorative finish.

It is widely used because it is durable, corrosion-resistant, eco-friendly, and cost-effective compared to liquid

paints.

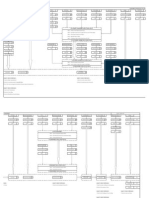

PROCESS FLOW

🔹 Basic Steps of Powder Coating Process

1. Surface Preparation

•Purpose: Ensure the surface is clean, smooth, and free of oil, dirt, rust, or old paint.

•Methods:

• Degreasing / Chemical cleaning

• Shot blasting

• Phosphate coating (for better adhesion & corrosion resistance)

2. Powder Application

•Electrostatic Spray Gun: A device used to apply charged powder particles onto the metal surface.

3. Curing Oven: A controlled heat oven used to melt and cure the applied powder coating, forming a solid, durable film.

4. Cooling & Inspection

•The coated part is cooled to room temperature.

•Final inspection is done for:

• Film thickness

• Adhesion

• Gloss / color consistency

• Surface finish

COMMON TEST

➢ Flexibility or Bend Test:

•A test to check how well a powder coating can withstand bending or deformation of the substrate

without cracking, flaking, or losing adhesion.

•Flexibility/Bend Test checks whether the powder coating can bend with the metal without breaking.

Standards Used:

•ASTM D522 – Mandrel Bend Test

•ISO 1519 – Cylindrical Mandrel Bend Test

COMMON TEST

➢ Impact Load Test :

•A test to check how well a powder-coated surface can resist sudden impact or shock without cracking,

chipping, or losing adhesion.

• Impact Load Test checks if a powder coating can survive a sudden hit or shock without damage.

• It shows the toughness and durability of the coating.

Standards Used:

•ASTM D2794 – Standard Test Method for Resistance of Organic Coatings to the Effects of Impact.

•ISO 6272 – Falling Weight Impact Test

NECESSARY TEST

➢ DFT Testing : To maintain coating layer thickness as per our requirement.

➢ Gloss Test : To evaluate Gloss finish of powder by using Gloss meter. Value >90

considered good.

➢ Note : Before testing, instrument calibration should be check.

COMMON TEST

➢ Adhesion Test : measures how well the powder sticks to the part once it is fully

cured.

➢ Curing Test : is perform by rubbing a methyl ethyl ketone-soaked cotton swab

lightly over a cured panel or part.

COMMON TEST

➢ Salt Spray Test : It is a corrosion resistance test used to check how well a powder-coated surface can withstand a

harsh salty environment.

•The test is done in a salt spray chamber where a coated sample is continuously exposed to a fine mist of salt

solution (usually 5% NaCl, pH 6.5–7.2) at a controlled temperature (generally 35°C).

Standards Used:

•ASTM B117 (most common)

•ISO 9227 (NSS – Neutral Salt Spray)

TYPES DEFECTS

Definition of Powder Coating Defects:

Powder coating defects are flaws that occur on the surface of a component or

product during or after the powder coating process.

These defects can affect the appearance, performance, durability, and protective properties of the coating.

They may arise due to factors such as: Common Defect Types :

• Run down

•Improper surface preparation • Pin Holes

•Incorrect powder application • Cissing

•Curing process issues (temperature/time) • Orange Peel

•Contamination (dust, oil, moisture, etc.) • Peel Off

•Equipment or environmental conditions • Cracking

• Dirt /Dust

• Blistering

👉 In short: Powder coating defects reduce the coating’s functional or aesthetic quality.

RUNDOWN/SAGGING CAUSES

Flowing or dripping of paint from upper vertical surface to the lower part forming a tear-like or wavy appearance.

Causes of Powder Run Down Defect:

1.Excessive Film Thickness – Applying too much powder in one area causes it to melt and flow during

curing.

2.Improper Application Technique – Holding the spray gun too close or applying uneven passes

3.Excessive Powder Flow Rate – Very high powder output from the spray gun.

4.Incorrect Curing Temperature/Time – Too high curing temperature makes the powder overly fluid before

cross-linking.

5.Re-Coating without Proper Surface Prep – Applying a second coat without proper flash-off or sanding.

RUNDOWN/SAGGING PREVENTION

✅ Prevention Methods for Powder Run Down

1.Apply Recommended Thickness

1. Keep film thickness within Specification/Supplier guidelines (usually 60–90 microns).

2.Correct Spray Technique

1. Maintain proper spray gun distance (6–10 inches).

2. Move the gun at constant speed, avoid staying too long in one spot.

3.Optimize Powder Output

1. Adjust powder flow rate to avoid over-application.

4.Control Curing Conditions

1. Allow the powder coating to cure for the required amount of time.

2. Avoid overheating which makes powder too fluid before crosslinking.

5.Recoating Practices

1. If a second coat is required, sand/scuff lightly and allow proper flash-off before re-coating.

PIN HOLES CAUSES

• This phenomenon is characterized by the appearance of small holes on the painted surface after curing.

CAUSES:

1.Outgassing of Substrate : Porous metals (cast iron, aluminum castings, welds) release trapped gases during curing.

2.Surface Contamination :Oil, grease, rust, dust, silicone, or pre-treatment residues left on surface.

3.Moisture/Humidity : Moisture in compressed air line or high humidity in coating environment.

4.Improper Pretreatment : Improper cleaning, degreasing, or phosphating.

5.Incorrect Curing Conditions : Sudden or excessive heating causes rapid gas escape.

6.Poor Powder Quality / Storage :Using old, moisture-contaminated, or poor-quality powder.

PIN HOLES PREVENTION

✅ Prevention of Pinholes:

1. Surface Preparation

•Thorough cleaning, degreasing, and drying before coating.

•Proper pre-treatment (phosphate, chromate, or conversion coating).

2. Control Outgassing

•Use degassing primers or special powders formulated for porous substrates.

•Pre-bake porous metals (like castings) to remove trapped gases before coating.

3. Environmental & Process Control

•Keep compressed air dry and oil-free.

•Control booth humidity.

4. Application & Curing

•Apply recommended powder thickness (not too heavy).

•Follow proper curing cycle (time + temperature) as per supplier specs.

5. Powder Handling

•Store powder in dry conditions, away from humidity.

•Use fresh powder, avoid contamination.

CISSING CAUSES

• Cissing is when the powder coating pulls back and leaves round bare spots or thin patches on the surface

(looks like “fish-eyes”).

CAUSES :

1.Surface Contamination : 1. Oil, grease, dust, silicone, or release agents on the substrate.

2. Hand sweat, fingerprints, or cutting fluids not cleaned properly.

2.Poor Pretreatment : 1. Improper cleaning, degreasing, → residue/scaling remains.

2. Incomplete phosphating layer .

3.Moisture : 1. Moisture film on the surface before coating.

2. Incompatible coatings, sealants, or touch-up paints .

4. Powder Issues : 1. Contaminated or poor-quality powder.

2. Cross-contamination between different powder types or when two or more different powders get mixed)

CISSING PREVENTION

✅ Prevention of Cissing :

1. Surface Cleaning

•Ensure thorough cleaning, degreasing, and rinsing of all parts.

•Use proper pretreatment (phosphating).

•Avoid handling cleaned parts with bare hands (use gloves).

2. Eliminate Contaminants

•Keep the coating booth free from dust, oil, or silicone sprays.

•Ensure compressed air is dry and oil-free.

3. Powder & Equipment Care

•Store powder in clean, dry conditions.

•Prevent cross-contamination between different powders.

•Clean equipment and spray booth regularly.

ORANGE PEEL CAUSES

• Orange peel is a surface defect where the coating looks not smooth ,shiny and rough, uneven & wavy

texture instead of being smooth and glossy.

CAUSES :

1.Powder & Application Issues

•Applying powder too thick.

•Wrong spray settings.

•Poor quality powder or wrong particle size distribution.

2.Curing Problems

•Incorrect oven temperature (too low → powder doesn’t flow fully).

•Uneven or insufficient curing.

3.Substrate & Surface Preparation

•Rough or uneven surface before coating.

•Poor sanding, pretreatment, or metal surface defects.

ORANGE PEEL PREVENTION

✅ How to Prevent Orange Peel:

1. Control Powder Application

•Apply recommended film thickness (usually 60–90microns).

•Use correct spray gun settings and proper distance (6–10 inches).

•Avoid heavy coat in one spot.

2. Proper Curing

•Ensure correct oven temperature & curing time as per powder supplier.

•Regularly check oven calibration for uniform heating.

3. Surface Preparation

•Clean, sand, or polish substrate properly to ensure smooth base.

•Use proper pretreatment (phosphate).

4.Powder Selection

•Choose powders with good flow characteristics for smooth finishes.

•For critical smoothness, use “low orange peel” or “smooth flow” powders.

PEEL OFF CAUSES

• Peel off is when the powder coating loses adhesion and comes off (chips, or peels away) from the

Surface.

CAUSES :

1.Poor Surface Preparation

•Oil, grease, dust, or rust not removed before coating.

•Insufficient pretreatment (no or weak phosphating /shot blasting).

2.Contamination

• Greasing, cutting fluids, or moisture on base metal surface.

•Moisture in compressed air or handling after cleaning.

3.Improper Curing

•Under-curing → coating doesn’t bond properly.

•Over-curing → coating becomes brittle, easier to peel.

4.Wrong Application

•Too thick or too thin powder layer.

5.Incompatible Coating Layers

•Applying powder over existing old paint, oil-based coatings, or improper primers.

PEEL OFF PREVENTION

✅ How to Prevent Peel Off:

1. Thorough Cleaning & Pretreatment

•Degrease, clean, and pretreat (phosphate/shot blasting) the metal surface.

•Ensure cleaning is proper and parts are dry before coating.

2. Avoid Contamination

•Do not touch cleaned parts with bare hands (use gloves).

•Keep booth and compressed air clean, dry, and oil-free.

3. Correct Application

•Apply recommended film thickness (DFT).

4. Proper Curing

•Follow curing cycle (time + temperature) recommended by Powder supplier as TTR.

•Regularly check and calibrate oven temperature.

5. Use Compatible Systems

•If using primers or multiple coats, ensure compatibility with top coat.

CRACKING CAUSES

Cracking is a defect where the powder coating film develops visible cracks, splits, or breaks on the surface after curing.

•The coating loses flexibility and breaks instead of staying smooth.

•Cracks may appear immediately or later during use (stress, bending, weathering).

CAUSES :

1.Improper Curing

•Over-curing (too much heat/time → coating becomes brittle).

•Under-curing (weak bonding → cracks under stress).

2.Excessive Film Thickness

Very thick coating layers → shrink and crack during cooling.

3.Surface Issues : Poor surface preparation → weak adhesion.

•Sharp edges or welds causing stress points.

4. Powder Quality / Incompatibility : Wrong powder type for the application (e.g., rigid powder on flexible parts).

• Two or more different powders get mixed.

CRACKING PREVENTION

✅ How to Prevent Cracking :

1. Apply Correct Film Thickness

•Stay within recommended thickness (usually 60–90 microns).

•Avoid heavy build-up on edges and corners.

2. Control Curing

•Follow correct curing cycle (temperature + time) as per powder supplier.

•Regularly calibrate and check oven performance.

3. Proper Surface Preparation

•Clean, pretreat, and remove sharp edges before coating.

4. Choose Right Powder

•Use flexible/impact-resistant powders for parts that bend or flex.

•Avoid mixing different powder types.

DIRT/DUST CAUSES

Dirt/Dust defect is when atmospheric particles (dust, fibers, dirt, or powder lumps)

get trapped in the powder coating film.

CAUSES :

1.Unclean Environment :

• Dust, fibers, or dirt in the coating booth or air.

• Poor housekeeping in the coating/curing area.

2.Contaminated metal surface :

• Workpiece not cleaned properly (oil, rust, or dust left).

• Handling with dirty gloves or bare hands.

3.Powder Contamination : Powder mixed with dirt, fibers, or incompatible powders.

•Reclaimed (overspray) powder not filtered properly.

4.Compressed Air Contamination : Moisture, oil, or dust in the compressed air line.

5.Oven Contamination : Dust, dirt, or oil carried into the curing oven by airflow.

DIRT/DUST PREVENTION

✅ Prevention of Dirt/Dust Defect:

1.Proper Substrate Cleaning

1. Ensure thorough degreasing, phosphating, and rinsing.

2. Use clean, filtered water for washing.

3. Blow off dust with dry, oil-free compressed air.

2.Maintain Clean Environment

1. Keep powder coating booth closed and dust-free.

2. Avoid grinding, welding, or sanding work near the coating area.

3. Use air curtains or separation between coating and other processes.

3.Compressed Air Quality

1. Use filters/dryers to remove oil, water, and dust from compressed air.

2. Check regularly for leaks or contamination.

4.Powder Handling

1. Store powder in sealed containers in dry and clean conditions.

2. Sieve reclaimed powder before reuse to remove contaminants.

5.Operator Practices

1. Wear clean, lint-free clothing and gloves.

2. Avoid touching cleaned parts with bare hands.

3. Follow strict hygiene and handling rules.

6.Regular Housekeeping

1. Clean floors, walls, and equipment regularly.

2. Use vacuum cleaners instead of sweeping to prevent dust rising.

BLISTERING CAUSES

Blistering is the formation of small to large bubbles on the powder-coated surface caused by trapped gases,

moisture, or contaminants beneath the coating film during curing.

CAUSES :

1. Moisture or Oil Contamination : Presence of water, oil, grease, or fingerprints on the surface before coating.

• Keeping powder coating material in a place where there is too much moisture or dampness in the air.

2. Improper Surface Preparation : Incomplete cleaning (dirt, dust, rust, mill scale, chemical residues).

• Poor degreasing or insufficient pre-treatment.

3. Entrapped Air or Gas : Air or volatile gases trapped under the coating during curing.

• Outgassing from porous substrates like cast iron, aluminum, or galvanized steel.

4. Incorrect Curing Process : Too high curing temperature or too rapid heating causes gases to expand.

• Non-uniform curing oven temperature.

5. Contaminated Powder : Mixing with incompatible powders.

• Recycled or overused powder with degraded flow properties.

BLISTERING PREVENTION

✅ How to Prevent Dirt/Dust :

1. Proper Cleaning & Pre-treatment

1. Ensure substrate is free from oil, grease, moisture, dust.

2. Use proper chemical pre-treatment (phosphate, chromate, etc.).

2. Dry Substrate & Powder

1. Dry substrate thoroughly before powder application.

2. Store powder in a cool, dry place (below 25°C & <50% RH).

3. Check Substrate Quality

1. Pre-bake porous materials (castings, welds) to release gases before coating.

4. Controlled Application Environment

1. Apply powder in a clean, humidity-controlled area.

5. Correct Curing Process

1. Follow recommended curing cycle (temperature & time).

2. Avoid rapid heating that traps gas under the coating.

THANK YOU