Maintenance Manual: Two (12) Quayside Container Cranes

Uploaded by

madadhiaMaintenance Manual: Two (12) Quayside Container Cranes

Uploaded by

madadhiaTWO (12) QUAYSIDE CONTAINER CRANES

AT

APMT TANGIERS MED 2, MOROCCO

PROJECT NO.: ZP16-2452

MAINTENANCE MANUAL

(HYDRAULIC PART)

Revision Description Date Name Approved by

SHANGHAI ZHENHUA HEAVY INDUSTRIES CO., LTD,

January, 2017

Hydraulic Manual for 12 sets Crane ZP16-2452

Content for Hydraulic Manual

1 Hoist Brakes Hydraulic System

1.1 Working Control

1.2 Hydraulic Schematic Drawing

1.3 Hydraulic Parts List

1.4 HPU Drawing

1.5 Valve Assembly and Pump Assembly

2 Trim/List/Skew & Rope Tension Hydraulic System

2.1 Working Control

2.2 Hydraulic Schematic Drawing

2.3 Hydraulic Parts List

2.4 HPU Drawing

2.5 Valve Assembly and Pump Assembly

2.6 Cylinder Drawing

3 Clamp Brakes Hydraulic System

3.1 Working Control

3.2 Hydraulic Schematic Drawing

3.3 Hydraulic Parts List

3.4 HPU Drawing

3.5 Valve Assembly and Pump Assembly

4 Maintenance of Hydraulic System

5 Commission of Hydraulic System

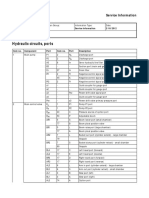

6 Parts Information

6.1 KEA 200L4A B5(400V-50Hz) Motor KRF

6.2 KEA 132S4A B5(400V-50Hz) Motor KRF

6.3 SCA4S/40/1.0/B/M/A(400V/50Hz) Oil cooler HYDAC

6.4 DF BN/HC240 TE10 B1.0 Pressure line filter HYDAC

6.5 RF BN/HC330 DE 10 B1.0 Oil return filter HYDAC

6.6 RF BN/HC110 DC 10 B1.0 Oil return filter HYDAC

6.7 ELFP7F10W1.0 Air breather HYDAC

Hydraulic Manual for 12 sets Crane ZP16-2452

6.8 DVP6-01.X Throttle valve HYDAC

6.9 CWEA-LHN Counterbalance vavle SUN

6.10 RDFA-LWN Relief valve SUN

6.11 CXFA-XAN Check valve SUN

6.12 KC-011/30 Compensate valve ATOS

6.13 B2T-A48SS-P5 Pressure relay BARKSDALE

6.14 D04B2-2.1N Check valve STERLING

6.15 D04B2-0.1N Check valve STERLING

6.16 D06B2 H2-2.1N Check valve STERLING

6.17 RV3-10-S-0-36 Relief valve EATON

6.18 FCV7-10-C-0-FF/40 Throttle/Check valve EATON

6.19 SV13-10-CM-0-240AGH Directional valve EATON

6.20 NV1-10-R Throttle valve EATON

6.21 NV1-10-K Throttle valve EATON

6.22 A10VSO 71 DRS/31R-VPBU99-S2 Pump REXROTH

6.23 A10VSO 18 DFR1/32R-PPA12N00 Pump REXROTH

6.24 AZPF-1X-011RCB20MB Pump REXROTH

6.25 4WE6D-6X/EW230N9K4 Solenoid valve REXROTH

6.26 4WE10D-3X/CW230N9K4 Solenoid valve REXROTH

6.27 DB10-1-5X/315 Relief valve REXROTH

6.28 DBDS6K1X/315 Relief valve REXROTH

6.29 Z2DB6VC2-4X/A200B100 Relief valve REXROTH

6.30 DR6DP2-5X/150YM Recompression valve REXROTH

6.31 AB31-14/1-1A Oil tank thermoster REXROTH

6.32 SLWC-60-1-B500NC-01-01-1-T70NC-PG11 Oil level switch STAUFF

6.33 SLWC-60-1-B250NC-01-01-1-T70NC-PG11 Oil level switch STAUFF

6.34 SPB-S-5-10-S080-A Air breather STAUFF

6.35 SNA127B-S-T-12 Oil level gauge STAUFF

6.36 SNA254B-S-T-12 Oil level gauge STAUFF

6.37 EHV10-330/90 Accumulator PARKER

6.38 EHV4-350/90 Accumulator PARKER

6.39 SYN-WDPFA/UDFS-MD2-ZCC- Synchronous valve WANDFLUH

6.40 200L-A10VSO71/32-ROTEX42 Coupling KTR

Hydraulic Manual for 12 sets Crane ZP16-2452

6.41 132S-AZPF-011RC-ROTEX28 Coupling KTR

6.42 132S-A10VSO18-ROTEX28 Coupling KTR

For more Information:

Parker: www.parker.com

Hydac: www.hydac.com

Rexroth: www.rexroth.com

Stauff: www.stauff.com

Sun: www.sunhydraulics.com

Eaton: www.eatonhydraulics.com

Barksdale:www.barksdale.com

Sterling:www.sterling-hydraulics.co.uk

Krf:www.Keruifu.com

Ktr:www.ktr.com

Wandfluh:www.wandfluh.com

Description of hoist Disc Brake Hydraulic System

1. Hardware:

1.1 Pump Motor M: 5.5KW1450rpm 400V-50Hz 1x

MH 230V50HZ

MT 24VDC

1.2 Solenoid S1,S2: 230V50HZ 2x

1.3 Pressure Relay H: 24VDC 1x

1.4 Float level switch L/T : 24VDC 1x

1.5 Limit Switch for cylindersR1—R4: 4x

1.6

*Each pressure relay has 2 contact. One is high pressure contact, the other is low

pressure contact.

2. Working Order: press "wheel brake" button or gantry, S is de-energized and start to

brake 2.1 Pressure Relay H is used to control Pump motor M.

Low-Pressure Pump motor High-Pressure Pump motor M

contactor of the M will be contactor of the will be de-

Pressure Relay energized. Pressure Relay energized

HL opens, sends HH closes, send

out a signal out a signal

2.2 Hoist Operate:

When Hoist “up/down” drive The solenoid S1, S2 will be

joystick leaves zero position. energized at the same time

The pump M is controlled by and the Hoist Disk Brake

the pressure relay H high and H begin to release.

low.

Only when the contactors of Limit Switch are closed and send a signal to

indicate the Hoist Disk Brakes have been released completely, with PC process,

the Hoist low speed disc brake begin to release, then the Hoist operate is

permitted.

2.3 Hoist Stop:

When the Hoist “stop” drive The pump M stop and the solenoid

joystick returns zero position. S1 ,S2 will be de-energized at same

time. The Hoist Disc Brake close.

3 Fault & Protection

3.1 When the oil temperature is higher than the preset value,the temperature contactor T

of the High temperature & Float switch will open and send out a high- temperature

signal to stop pump motor .There should be a fault display such as “Oil temperature of

Hoist brake system too high”and system alarm.

3.2 When the oil level is lower than the preset valve,the contactor L of the High

temperature & Float switch will open and send out a low level signal to stop pump

motor .There should be a fault display such as “Oil level of Hoist brake system too

low”and system alarm.

3.3 Emergency Stop:

When Hoist overspeed or Emergency Stop, the solenoid S1,S2 will be de-energized

immediately, the Pump Motor M will be de-energized.

.

3.4 If the pump motor M energizes 4 times in 10 minuteS in automatic-pressure-

maintenance state, the motor shall stop and system alarm and display a fault “Hoist disc

brake system motor start too frequently”.

3.5 When control on, if the motor continuously run more than 2 minutes, motor shall

stop and system shall alarm and display a fault “ time of Hoist disc brake system motor

running too long”.

750 900

1330

250

250

510 75 460

700 750

Engineering requirements

1.The Power station should be concise and beautiful .all The pipeline exports should

be sealed up by plastic cap or plastic film to prevent sundry from going into the

pipelines.

2.In the station the pipelines and the other parts should be easily assembled and

disassembled.The layout of the pipelines should be reasonable.

3.When processing,the location of the welding parts should be reasonably placed and

the other parts shouldn’t be bruised. 。The burned parts should be cleaned up for

subsequent processing

4. The welding point of the oil tank should be passivated.the oil tank should be

cleaned up before assembling and there’s no sundry.It should be given a stationary

test with a pressure of 0.5bar.

5. After the Initial assembly ,the pipelines should be chamfered and the chips should

be removed and has acid pickling as well.they should not be wiped by cotton cloth.

6. The paint coating of the power station should be conducted according to ZPMC

7. Every part should have its Stainless steel plate in accordance with the Schematic

diagram nameplate and should be fixed with rivets

8. Functional tests should be carried out for the Components of the power station to

ensure the perfect function of the power station.after final assembly, debug

according

to the given parameters and technological requirements of standard and keep

records

on file.

Technical parameters

1. Motor model:KEA 132S4A B5 5.5KW 400V50HZ;

2. Gear Pump model: AZPF-1X-011RCB20MB; Displacement: 11cc/r

3. Solenoid valve control voltage: :230V50Hz

4. The system working pressure:135-155BAR ;Relief valve set

pressure:170BAR;

Accumulator nitrogen charging pressure:110BAR

5.System flow:4LPM; working medium: L-HM46 Anti-wear

Hydraulic Oil

6. Effective volume of the oil tank :80L;

7. Power station exit B1 : M18*1.5

160

528

130

130

170

253 252

150

Technical parameters

110

1.Oil port size P1 、P2、Px、B: M18*1.5,T: G3/4 ;

2.Solenoid valve voltage is 230VAC 。

The Multi-function Hydraulic System

TLS/List /Trim/Skew & Wire Rope Tension

A: TLS/List/Trim/Skew/ Hydraulic System

Hardware:

Pump Motor M1: M1A,M1B (400V/50HZ 30KW 1480rpm)

1 Motor heater M1H: M1AH,M1BH (230V/50HZ) Qty:2

Motor thermometer M1T: M1AT,M1BT (24VDC)

S1, S2, S3, S4, S5, S6, S7 , S8

2 Proportional valve: (24VDC power supply, 4-20mA command Qty: 8

value input)

3 Solenoid:S9 S9A,S9B (230V/50HZ) Qty: 2

4 Limit Switch D1 For Isolator Valve : D1A, D1B (24VDC) Qty: 2

Sensor of Cylinders 24VDC power supply,4-20 mA command Qty: 4

5

SA SC SB SD : value output

Working order:

1. In Operator's Cab/ on Control Panel:

1.1 When crane control power on, the Pump Motor M1A will be energized

automatically. Only when the contactor of the Limit Switch D1A which is used

for valve has been closed, the Pump Motor M1A can be energized. When

crane control power off, the Pump Motor M1A will be deenergized

automatically.

1.2 One “Trim/List/Skew-Left/Skew-Right” joystick will be mounted on the

operator's console to operate the list/trim/skew function.

1. 3 One "Trim/List/Skew Home" pushbutton and green indicator will be mounted

on the operator's console. After pressing this pushbutton, the spreader will do

the "Home" motion, the corresponding solenoids will be energized. when any

of the four TLS cylinders returns to the Home position, the corresponding

solenoid will be de-energized. Only when all the four TLS cylinders return to

the Home position, the green indicator will be lighted.

2 Trim / List / Skew :

2.1 The relationship between the moving direction of four TLS cylinders and the state

of 8 proportional solenoids and 1 normal solenoids( energize or deenergize).

Four Encoders will be used to measure and control the position and movement

of the four TLS cylinders. The solenoid S9A is used to control the oil pressure of

Pump Motor M1. When any of the 8 proportional solenoids S1~S8 is energized,

the solenoid S9 will be energized at the same time. Only after de-energizing all of

the 8 proportional solenoids S1~S8, then the solenoid S9A can be deenergized.

2.2 The Spreader Trim/List/Skew motions:

S1 S2 S3 S4 S5 S6 S7 S8 S9A

List outboard + + + + +

List inboard + + + + +

Trim left + + + + +

Trim right + + + + +

Skew CCW + + + + +

Skew CW + + + + +

Symbol "+" mean that the corresponding solenoid will be energized.

2.3 As we say the Trim/List/Skew motion, we define the following :

2.4 Speed control of Trim/List/Skew

The eight proportional solenoids are used to control the movement speed of

the four TLS cylinders (A, B, C, D) separately.

Spreader’s Movable distance Movable speed Energized solenoid Beginning

angle of cylinder of cylinder (valve) command value

S2, S8 (PV1, PV4) 18.27 mA (78.4%)

List outboard 3° 155mm 155mm/10sec

S3, S5 (PV2, PV3) 7.36mA (58%)

S1, S7 (PV1, PV4) 7.36mA (55%)

List inboard 3° 155mm 155mm/10sec

S4, S6 (PV2, PV3) 18.27 mA (78.4%)

S1, S3 (PV1, PV2) 7.6mA (55%)

Trim left 3° 130mm 130mm/10sec

S6, S8 (PV3, PV4) 18.08mA (76%)

S2, S4 (PV1, PV2) 18.08 mA (76%)

Trim right 3° 130mm 130mm/10sec

S5, S7 (PV3, PV4) 7.6mA (55%)

S1, S5 (PV1, PV3) 8 mA (50%)

Skew CCW 3° 125mm 125mm/10sec

S4, S8 (PV2, PV4) 18 mA (75%)

S2, S6 (PV1, PV3) 18 mA (75%)

Skew CW 3° 125mm 125mm/10sec

S3, S7 (PV2, PV4) 8 mA (50%)

When the cylinders move, the PLC should always control the speed of the

four cylinders.

Movement of the four TLS cylinders must synchronize. The synchronization

tolerance is 2%.

2.5 Trim/List/Skew Home

When press the “Trim/List/Skew Home" pushbutton, the spreader will do

“HOME” motion. PLC program will send signal to energize the corresponding

solenoid (among S1~S8 and S9A), the corresponding cylinders will move.

These four cylinders must reach the home position at the same time. Use the

proportional directional valve to control the flow volume and direction of the

separate cylinder. When four TLS cylinders returned to home position which

has been remembered, the corresponding solenoids should be de-energized.

2.6 Full travel from level to full tilt in either direction shall be accomplished in 10

seconds. The speed of trim/ list/ skew will be controlled by proportional valves,

PLC send command value signal through WANDFLUH electrical amplifier to

control the flow volume of proportional valve. And the speed of cylinder

movement will be controlled.

2.7 Speed control of Trim/List/Skew Home

After spreader do the trim, list and skew function, every cylinder stop at different

position. After operator press the “home” button, PLC measure the position of each

cylinder through the sensors mounted in the cylinders.

Following variable is defined:

Dn, n=A, B, C, D。Cylinder displacement output by sensor。

D0: home position diaplacement of cylinders

Aa: piston side area of cylinder Aa=380.13cm2

Ab: rod side area of cylinder Ab=179.07cm2

Qp —pump out flow, Qp=99 L/min

△Dn n=A, B, C, D, displacement of corresponding cylinder rod relative to home

position。

△DA= DA-D0

△DB = DB-D0

△DC= DC-D0

△DD= DD-D0

If △Dn>0, means corresponding cylinder rod retracted relative to its home position

If △Dn =0, means corresponding cylinder rod at its home position

If △Dn <0, means corresponding cylinder rod extended relative to its home position

Qn n=A, B, C, D

QA—flow into cylinder A

QB—flow into cylinder B

QC—flow into cylinder C

QD—flow into cylinder D

Vn n=A, B, C, D

VA—speed of cylinder A to extend or retract

VB—speed of cylinder B to extend or retract

VC —speed of cylinder C to extend or retract

VD—speed of cylinder D to extend or retract

Use above values, PLC can calculate the state of each cylinder (extend or retract), and

send out command current to control the direction and flow volume of the cylinder.

Control thoughts is like following:

①system first detect ②calculate the total ③figure out total

all the position of the volume of oil to all the time to use to finish

cylinder and aimed cylinder to finish each the work according

destination and know length according each to pump max. out

the direction and responding area* and flow and each

work out length for each volume of oil to cylinder speed** and

each cylinder to flow into each cylinder each cylinder oil

finish that make the cylinder flow into it

get to the destination

④select ⑤work out ⑥ compare ⑦according to

signal value cylinder’s instantaneous relationship

of current to actual speed with between flow and

individual instantaneous desirous speed to signal current to

proportional speed from decided the flow know the current

valve every PLC to be added or to add or reduce

according cycle and its reduced

formula journey in this

cycle

⑧notify system to make ⑧every several PLC cycles Until cylinders

readjustment. This cycle system re-detect destination arrive desirous

from ⑤ to here is and make cycle from ①, but destination

occurring at each PLC based current from now

cycle.

* when fill oil to piston side, area is bore area Aa=380.13cm2 ,when fill into rod side,

the area is annular area 179.07cm2

** each cylinder speed according to is the cylinder area, the area of rod side or piston

side.

For example, do home motion:

PLC first get the value DA, DB, DC, DD.

Then △Dn,n=A, B, C, D

Min. time of cylinders to home:

1 4 Dn

tr ( ( Dn A)) ,each cylinder speed: Vn

Q p n1 tr

if △Dn>0, cylinder should retract to home with solenoid S1or S3 or S5 or S7 being

energized with command value within 12-4mA to make flow from P to B and A to

T,A=Ab.

If △Dn<0,cylinder should extend to home with solenoid S2 or S4 or S6 or S8 being

energized with command value within 12-20mA to make flow from P to A and B to

T, A=Aa。

Flow into corresponding cylinder should be:

Qn Dn A / t r

According to the manual of Rexroth proportional valve, we know the following

relationship between flow output of valve and input command signal value current at

valve’s pressure drop in each way 10 bar:

If △Dn >0, I I 12 n 8 ; within 12-4mA; n (20 40Qn / 14) %

Q n (L / min)

When Qn=17L/min n 0.55 55% , I I 12 n 8 =7.6 mA

If △Dn<0, I I 12 n 8 ; within 12-20mA; n (20 40Qn / 28) %

Qn (L / min)

When Qn=34L/min n 0.784 78.4% , I I 12 n 8 =18.27mA

This value is initial given to valve, during motion of the cylinder, this value should be

adjusted by following thoughs to reduce or eliminate influence of oil viscosity

changing, tolerance of valve core, pressure compenstor’s pressure differential

fluctuating, non-exactitude of the relationship between flow output and input

command value, ect.:

In a PLC cycle, from the cylinder displacement of Dnt1 at t1 time obtained from

cylinder position sensor and Dnt 2 at t2 time obtained from cylinder position sensor the

cylinder’s instantaneous speed can be work out:

Dnt 2 t1 Dnt 2 Dnt1 ,n=A, B, C, D

Tn t 2 n t1n

Dnt 2 t1

Vnf n=A, B, C, D

Tn

Speed tolerance: Vn Vn f Vn n=A,B,C,D

According to system acknowledge, following relation formula is given:

3Qn 3Vn A

n (100%)

2 2

I n n 8 mA

2

when cylinder extend,A= Aa =380.13cm

when cylinder retract, A=2 Ab =2x179.07=358.08 cm2

Signal current

I 8

n n mA should be added or subtracted from current

signal current, to make more correct of cylinder speed and same time to get to

destinnation.

Every several PLC cycle, every actor should recognize its aimed destination and

work out time again speed again and readjust the command value based on current

value.

2.8 When cylinders do “home” function, PLC should be always detected the signal

of the sensors which are mounted on the cylinders, and calculate the speed

value of the cylinder, revise the command current constantly.These four

cylinders must return to home position synchronously. The synchronization

tolerance is 2%.

3. The working order of the TLS cylinder automatic-oil-replenish for cylinder

internal oil leakage. (That is the TLS cylinder operation position remember

and maintenance. )

After finishing any one time Trim/List/Skew/Home motion, the current position

of the four TLS cylinders (A, B, C, D) will be remembered by PLC program.

During the crane operation, if the deviation of any four TLS cylinders (A, B,

C, D) is greater than 10mm(because of internal oil leakage) in 10 minutes,

PLC displacement detection system will send signal to energize the

corresponding solenoid(among S1~S8 and S9A), the corresponding cylinders

will move. When any of four TLS cylinders returned to previous position which

has been remenbered, the corresponing solenoid will be deenergized. Above

procedure is called automatic-oil-replenish.

When the snag happen, the automatic-oil-replenish system is unvalid.

When spread rotates over a certain range, Motor M1B start,the solenoid

valve S9B energized, until the spread return to the normal range, Motor M1B stop

and S9B de-energized。

B: Trolley’s and Catenary Rope Tension hydraulic system

Hardware:

Tension motor M3: 5.5KW 1450rpm 400V/50Hz 1x

1 Motor heater M3H: M2H (230V/50HZ)

Motor thermometer M3T M2T(24VDC)

2 Solenoid S10,S11,S12: 230V/50HZ 3x

Pressure relay H5 for Trolley, H6 for 24VDC

3 Catenary (each pressure relay has 2x

two contactor):

4 Limit Switch D3 For Isolator Valve : D3 (24VDC) 1x

Limit switch LS1~LS4 for trolley’s 24VDC

5 4x

rope tension cylinder

Limit switch LS5~LS8 for Catenary’s 24VDC

6 4x

rope tension cylinder

1. When boom is level, the system should maintain pressure and tense

automatically.

When power control on, the tension motor M3 should be energized. Only

when the contact of the Limit Switch D3 which is used for valve has been closed,

the Pump Motor M3 can be energized. When power control shut off, the tension

motor M3 should be de-energized.

a. Only when the low contact of the pressure relay H5 and H6 close, trolley can

do move.

b. If the low contact of the pressure relay H5 or H6 open with 10 seconds,

trolley can do move slowly only. There should be a fault display such as “Trolley &

Catenary Hydraulic Tension is Trouble", and system alarm.

c. When trolley move, solenoid S11 and S12 should be de-energized. When

trolley stop, after 5 seconds, the solenoid valve S11 and S12 should be energized for

3 seconds.

d. When any of the eight limit switches (LS1~LS8) is touched, the trolley motion

is prohibit, and system alarm.

2. When boom up or down.

a. When boom is going up, the Motor M3 will be energized, the solenoid S10,

S11 & S12 should be energized.

When the high contact of the pressure relay H5 or H6 open, (when there give the

boom order, if the high contact of the pressure relay H5 or H6 open over 5s) boom

cannot do up and down. there should be a fault display such as “Trolley & Catenary

Hydraulic Tension is too high”,

b. When boom is going down, the Motor M3 will be energized, the solenoid S10,

S11 & S12 should be energized.

c. When boom stop at any other positions besides level position, the pump

motor M3 will stop and the solenoid S10, S11 & S12 should be de-energized.

d. When boom lower to Level position, the Motor M3 will be energized, the

solenoid S10, S11 & S12 should be de-energized, The system will be under the

maintain pressure and tension status automatically.

e. When boom is Stowed/Maintenance position, both the Motor M3 and the

solenoid S10, S11 & S12 will be de-energized.

3 Every tension cylinder is equipped with two limit switches. (Provided by the

mechanism)

C: Others

Hardware:

1. Thermometer(one point) T2 (24VDC) Qty: 1

2 Float switch L and temperature T1 L,T1(24VDC) Qty: 1

3 Cooler M 4(400VAC/50Hz,1.5KW) Qty: 1

1. When the power control on, if the oil temperature is higher than the preset

value of the higher temperature,the high oil temperature contractor T2 of the

Thermometer will open and send out a higher temperature signal to energize the

Cooler M4. when T2 close and send a signal ,after twenty minutes the Cooler M4

will de-energized.

2. When the power control on, if the oil temperature is higher than the preset

value of the too-high temperature,the high oil temperature contractor T1 of the

Thermometer will open and send out a too-high temperature signal to stop the

Motor M1A,M1B,M3. There should be a fault display such as "Oil temperature of

Multi-function hydraulic system is too high", and system alarm.

3. When the power control on, if the oil level of the oil tank is lower than the

preset value, the Float Switch L will open and send out a signal to stop the Pump

Motor M1A, M1B,M3. There should be a fault display such as "Oil level of Multi-

function hydraulic system is low", and system alarm.

B9.15 B9.12

B9.14

B45.1

B8.2

264

B47

B46

B9.16

185

B48.1 B42 B9.11

B41

160 274 160

B43.1 B48.2 B43.2

Technical parameters

1、The system working pressure :6Mpa-11Mpa;

2、 Port size P2 T3 C1 C2 PX1 PX2 :M18*1.5;

B44.2 B45.2

B44.1

B9.13

Description of Wheel Brake Hydraulic System

1. Hardware:

1.1 Pump Motor M: 5.5KW1450rpm 400V-50Hz 1x

MH 230V50HZ

MT 24VDC

1.2 Solenoid S: 230V50HZ 1x

1.3 Pressure Relay H: 24VDC 1x

1.4 Float level switch L/T: 24VDC 1x

1.5 Limit Switch for cylinders R1-R8: 8x

*Each pressure relay has 2 contact. One is high pressure contact, the other is low

pressure contact.

2. Working Order:

2.1 Pressure Relay H is used to control Pump motor M.

Low-Pressure Pump motor High-Pressure Pump motor M

contactor of the M will be contactor of the will be de-

Pressure Relay energized. Pressure Relay energized

HL opens, sends HH closes, send

out a signal out a signal

2.2 Press "release" button release gantry drive is allowed hold on the pressure

automatically system will brake if gantry stops for 5 minutes

press "release" buttom or gantry drive 8 limit switches R1-R8

joystick leaves zero position, Solenoid signals send out a signal and

S and motor M will be energized, green indictor lights, it means

accumulator and pump supply oil to the crane has been released,

wheel brakes , the system release starts gantry drive is allowed

when High-Pressure contactor of gantry stops Solenoid S is

the Pressure Relay HH close, send de-energized

out a signal, M is de-energized for 5 minutes

2.3 Press "wheel brake" button brake

press "wheel brake" button or R1-R4signal, red indicator light and it

gantry drive joystick returns means system in braking state

zero position, S is de-energized

and start to brake

3 Fault & Protection

3.1 When the oil temperature is higher than the preset value,the temperature contactor T

of the High temperature & Float switch will open and send out a high- temperature

signal to stop pump motor .There should be a fault display such as “Oil temperature of

wheel brake system too high”and system alarm.

3.2 When the oil level is lower than the preset valve,the contactor L of the High

temperature & Float switch will open and send out a low level signal to stop pump

motor .There should be a fault display such as “Oil level of wheel brake system too

low”and system alarm.

3.3 Emergency Stop:

When the speed of wind is over the value or Emergency Stop, the solenoid S and the

pump motor M will be de-energized immediately.

3.4 If the pump motor M energizes 4 times in 10 minuteS in automatic-pressure-

maintenance state, the motor shall stop and system alarm and display a fault “wheel

brake system motor start too frequently”.

3.5 When control on, if the motor continuously run more than 2 minutes, motor shall

stop and system shall alarm and display a fault “ time of wheel brake system motor

running too long”.

560 860

Technical parameters

1. Motor model:KEA 132S4A B5 5.5KW 400V50HZ;

2. Gear Pump model: AZPF-1X-011RCB20MB; Displacement: 11cc/r

3. Solenoid valve control voltage: :230V50Hz

4. The system working pressure:120-140BAR ;Relief valve set

pressure :160BAR;

Accumulator nitrogen charging pressure:100BAR

5.System flow:3.3LPM; working medium: L-HM46 Anti-wear

Hydraulic Oil

6. Effective volume of the oil tank :50L;

7. Power station exit B : M18*1.5

1354

1290

A A Engineering requirements

1.The Power station should be concise and beautiful .all The pipeline exports should

be sealed up by plastic cap or plastic film to prevent sundry from going into the

B pipelines.

420 750 2.In the station the pipelines and the other parts should be easily assembled and

disassembled.The layout of the pipelines should be reasonable.

500 800 3.When processing,the location of the welding parts should be reasonably placed and

the other parts shouldn’t be bruised. 。The burned parts should be cleaned up for

subsequent processing

4. The welding point of the oil tank should be passivated.the oil tank should be

cleaned up before assembling and there’s no sundry.It should be given a stationary

test with a pressure of 0.5bar.

5. After the Initial assembly ,the pipelines should be chamfered and the chips should

be removed and has acid pickling as well.they should not be wiped by cotton cloth.

6. The paint coating of the power station should be conducted according to ZPMC

7. Every part should have its Stainless steel plate in accordance with the Schematic

diagram nameplate and should be fixed with rivets

8. Functional tests should be carried out for the Components of the power station to

ensure the perfect function of the power station.after final assembly, debug

according

to the given parameters and technological requirements of standard and keep

records

on file.

957

210

120

130

130

191

Technical parameters

258

1.Oil port size P1、P2、Px、B: M18*1.5,T: G3/4;

2.Solenoid valve voltage is 230VAC 。

Maintenance and Repair of Hydraulic System

I. Trial Run of the Hydraulic System

1. Cleanliness of the hydraulic system

Prior to filling the oil, cleanliness of the reservoir, cylinders and piping must be

checked and ensured. If any contamination is found in the system it must be

recleaned thoroughly. The pump station on the crane may be used as oil supply

for the system blushing with some additional auxiliary piping. The cleaning

should be done as the following:

1.1. Clean up the appropriate site working area first;

1.2. The reservoir must be cleaned first. Then filled with oil and heat the oil up to

45°C~55°C. During flushing oil flow rate in piping shall reach 5~7m/s as far as

possible, and the relief valve shall be set less than 5.0MPa. A filter shall be

mounted on the return line.

1.3. Flushing is made for main piping and may be performed separately for sections

into which the piping is divided. Discharge or drain ports of hydraulic valves

should temporarily be shut off and connected to the flushing pipeline. The

directional valves should be activated to a certain position to make oil circulation

possible.

1.4. During system flushing piping should be shocked frequently and slightly by

hammer to assist the dirt and rust. 30 minutes later, the splotches of rust should

be removed and checked, then cleaned and reassembled. Repeat flushing

several times until the oil filter has no obvious contamination. This will take

about 2~3 hours for one flushing section. If it is cleaned by hydraulic oil, then

after cleaning the hydraulic oil must be tested and if the test result shows the oil

is satisfactory in respect of physical and chemical properties it can still be used.

1.5. Check oil's cleanliness after all the pipes have been cleaned. If the oil extend to

SAE 5, pipes can reset and repair to commission the hydraulic system. If not,

you shall repeat 1.3 and 1.4 until the oil cleanliness is SAE 5.

1.6. Please check the oil cleanliness again after finish commissioning the hydraulic

system. Repeat 1.1~1.5 if oil cleanliness has not extend to SAE 5.

2. Adjusting and testing of the hydraulic system:

It is necessary for either new or repaired hydraulic equipment to adjust and test

the performance data to fit practical data required for the specified application.

2.1. Purpose of the adjustment and test

We can know and familiarize with system performance and technical conditions

by adjustment and trial running. Defects and faults found during trial run shall

be eliminated and remedied immediately and thus reliable operation of hydraulic

system can be ensured.

2.2. Main contents of adjustment and test

2.2.1. Main data, such as force, speed, start point and end point of stroke, period of

each motion and total time taken for duty cycle, are to be adjusted to the valve

determined during original designing.

2.2.2. Adjustment of the complete system to make the system performance reaching

stable and reliable operation.

2.2.3. During adjustment the power loss of the hydraulic system should be evaluator

and the temperature rise of oil should be observed.

2.2.4. Reliability of each adjustable components should be checked.

2.2.5. Reliability and sensitivity of each control mechanism should be checked.

2.2.6. All those components which are not in compliance with design requirement

and/or with certain defects found should be remedied or replaced.

2.3. Method of adjustment and points for attention

In hydraulic system the power is transmitted by fluid pressure so that reasonable

setting is very important for ensuring normal system operation.

2.3.1. Familiarize with hydraulic system and its technical performance.

a) It is necessary to familiar with each pressure component and the entire system

feature. And it is also necessary to understand the function and characteristics

of the

equipment adjusted, the equipment design, fabrication accuracy and application

as well as relationship between mechanical, electrical and hydraulic systems.

b) It is also necessary to analyze seriously structure, function, performance and

adjusting range of the component and the practical location of each component

on the equipment should be known.

c) Pressure adjustment method and steps and operation procedure should be

developed to avoid damage to the equipment and personnel injury as far as

possible.

2.3.2. Pressure adjustment method

The pressure in the hydraulic drive static pressure of fluid. Working pressure is

developed when an external force acts on the fluid surface. Therefore

adjustment of the system pressure is essentially resistance to free flow of the

fluid. The method is as follows:

a) Before pressure adjustment the adjustable screw of the pressure relief valve is

loosened and the limit position of the actuator should be adjusted.

b) The actuator moves to the limit and stops, or shut off the oil flow by some

component to build op pressure in the system.

c) Pressure should be adjusted according to design required working pressure or

practical necessary pressure (it should not exceed design working pressure) to

decrease power consumption and temperature rise as far as practicable and to

minimize possible leakage due to high temperature.

d) Pressure should be set(adjusted) gradually till the valve needed. After that the

adjustable screw should be secured by fastening the locking nut to avoid

loosening.

2.3.3. Pressure adjustment (setting) range

Reasonably set pressure of various components in the system is significant for

normal and stable operation of the system as well as for limiting temperature rise.

If system pressure is set inadequate excessive energy loss and high temperature

rise may be resulted in and cooperation of motions may be affected harmfully

and even fault may happen. Therefore, pressure setting must meet the

requirement under specifications

or according to practical application conditions. Pressure setting is to be

determined with consideration of construction, quantity, piping used.

a) Pressure relief valve rated pressure shall 150% of its set max. working pressure

at least.

b) If there is a pressure relay in the system, the pressure relay adjusting pressure

shall 0.2~0.5MPa high or low than the working pressure of executive agency

which is controlled by the pressure relay.

c) Accumulator's charging pressure is 80~90% of its min. working pressure if there

is a accumulator in the hydraulic system. Pressure relief valve of accumulator

adjusting pressure is 110~120% of the its max. working pressure.

d) If there is a DFR model variable piston pump in the system, its set max. working

pressure is 80~90% of set pressure of the pressure relief which is mounted at the

output of the pump. Its ready pressure shall be about 20bar.

e) Range of return line back pressure is 0.1~0.3MPa.

2.3.4. Point for attention during pressure setting

a) Pressure adjusting under actuator(hydraulic cylinders, motors) motion is not

allowed.

b) Pressure gauge should be checked before pressure adjustment and must be

replaced if it is abnormal.

c) Pressure is not allowed to be adjusted without pressure gauge. It is necessary to

install a pressure gauge then pressure can be adjusted.

d) Pressure setting should be as specified in operation instruction or as practical

necessary (but freighter than specified is not allowed) to prevent from excessive

pressure and resulted temperature rise.

e) The locking nut should be secured anti-loosened after pressure set.

2.4. Speed regulation and others

2.4.1. Pump output oil supply to the executive agency at all, so you need not adjust

speed.

2.4.2. If there is a DFR model variable piston pump in the system, pump flow

quantity

adjusting figure is 1~2 l /min more than set flow quantity of the throttle valve

mounted out of the pump.

2.4.3. The 4 cylinder's speed are almost the same for the multi-function hydraulic

system. Speed error range is 1% if adjust the throttle valve.

2.4.4. There is a throttle valve in the system which mount a accumulator. So

accumulator output flow quantity can controlled and avoid shock.

2.4.5. Low oil level alarm device is installed in the oil reservoir. In case of lose

breakage or seal damage at valves that may result in a large at valves that may

result in a large amount of leakage and the later will lower the oil level in

reservoir the alarm device will be activated and pomp motor stops. The alarm

is activated when the level fall to 100~150mm.

II. Maintenance of hydraulic system

Proper operation and careful maintenance for the equipment is necessary for

prevention from earlier worn-out and damage, and results in extended service

life. Regular maintenance of the equipment will make it always in proper

technical condition and having desired efficiency.

1. Maintenance requirement of the hydraulic system:

1.1. It is necessary to have skilled operation, reasonable adjustment, careful

maintenance and regular inspection and appropriate repair to ensure expected

productivity and stable, reliable technical performance of the hydraulic

equipment. In addition, the following requirements must be met during

hydraulic equipment operation:

1.1.1. Reasonably set working pressure and speed in accordance with design

requirement. After pressure and speed (flow) setting to specified valve

adjustable screw should locked securely to prevent from loosing, or adjustable

handle (if applicable) should be locked.

1.1.2. Hydraulic oil should be selected as specified in the operation instruction.

The oil must be filtered to SAE 5 before filling into the system. Samples must

periodically

be taken from the system and be tested. If the oil quality is found unsatisfactory

it must be replaced.

1.1.3. Temperature of the oil in hydraulic system on the crane should not be over

63°C, normally it should be limited within the range of 0°C~63°C. Whenever

the oil temperature exceeds specified valve the cause must be found and

eliminated.

1.1.4. To ensure normal operation of the pressure relief valves stable power voltage

is necessary and voltage surge should be limited within 5%~15%.

1.1.5. Operation with defective or without pressure gauge is not permitted.

1.1.6. Electrical panel, junction box, operation console and master switch box etc.

should be equipped with cover or door normally closed during operation and

operation with opened covers or doors is not allowed.

1.1.7. When some portion failure of the system occurs(such as unstable pressure ,low

pressure ,vibration etc.) it must immediately be checked and the cause must be

found. Do not continue operation with this failure or accident may happen.

1.1.8. Regularly check the cooler and heater operation performance.

1.1.9. Frequently check and fasten pipe fittings, flanges etc. to prevent from

loosening . Hydraulic hoses must be periodically replaced.

1.1.10. Periodically replace seals, usually the seal life is one and half to two years.

1.1.11. Periodically measure the main components performance or regularly replace

or repair them.

1.2. Operation and maintenance procedure:

In addition to the conventional requirements for usual mechanical

equipment ,there are Some special requirements which must be met by the

hydraulic equipment as follows:

1.2.1. The operator must familiar with the function of hydraulic components used on

the crane and hydraulic system principle and operation sequences well.

1.2.2. Operator shall frequently observe hydraulic system operation condition,

working

pressure, speed, cylinder and hydraulic motor condition to ensure stable and

reliable system operation.

1.2.3. When temperature on reservoir reaches 63°C, the system condition must be

paid attention to and appropriate measure for inspection and maintenance should

be taken.

1.2.4. The operator shall not damage the system interlock devices, not damage or

move any limit switches.

1.2.5. The operator is not allowed to adjust or replace any hydraulic component

without permission of the related authority.

1.2.6. The operator is not allowed to do any thing with the fault when some trouble

in hydraulic system occurs. He should immediately notify maintenance

department of the trouble. Maintenance department must immediately send

personnel related to the job site for trouble shooting.

1.2.7. Hydraulic equipment must be maintained clean and protected from dust cotton

waste etc. Getting into the reservoir.

1.2.8. The operator shall carefully make "point inspection" according to equipment

point inspection cards.

1.3. Point inspection and periodic inspection

Point inspection is the basic of equipment maintenance. Point inspection of

hydraulic equipment should be made for specified items to check if the hydraulic

is in proper condition and the operation is normal by observing appearance and

listening to the running or measuring by simple tools and instruments. This is

done for advanced finding out abnormal problems or imperfect condition which

maybe solved in advance to minimize risk of accident the latter will affect

productivity of the crane. All abnormal problems and imperfect condition may be

eliminated at their beginning through point inspection. According to the data

obtained by point inspection the items which need to be repaired can be

determined and a repair plan can be developed, also the regularity of trouble

occurring in the system and service life of oil, seals and components and period

of their replacement may be find out.

Point inspection is divided into two categorizes: routine point inspection made

by the operator and periodic inspection means inspection after an interval of

more than one month made by maintenance personnel after crane be stopped.

Point inspection cargo shall be included in technical files and can be one of the

bases for repairing.

Contents of the point inspection are as follows:

1.3.1. Check if there is external leakage at any valve, cylinder and/or pipe fitting.

1.3.2. Check if there is abnormal noise during pump or hydraulic motor running.

1.3.3. Check if the cylinders move smoothly and normally.

1.3.4. Check if all of the pressure measuring points are in specified range and

pressure is stable.

1.3.5. Check if oil temperature is within allowable range.

1.3.6. Check if there is high frequency vibration during system operation.

1.3.7. Check if the solenoid and electric controlled directional valves are sensitive

and reliable.

1.3.8. Oil level in reservoir is within normal level range or not.

1.3.9. Check if there is position deviation of limit switches or limit blocks, fastening

bolts ate secured reliably.

1.3.10. Check if there is abnormal condition during manual or automatic system

operation duty cycle.

1.3.11. Periodically take samples from reservoir to check oil quality.

1.3.12. Periodically check accumulator performance.

1.3.13. Periodically check the cooler and heater performance.

1.3.14. Periodically check and fasten all main bolts, nuts, fittings and flange bolts.

Point inspection is made by listening, observing and testing. Results of

inspection (check) may marked by four symbols: "√" means perfect; "Δ" means

abnormal: "X" means waiting for be repaired; "⊗" means already repaired.

These symbols shall be printed in the following table.

Daily Point Inspection Card

Operator:

Mechanical:

Electrical:

Hydraulic:

Equipment No: Model: Date:

Contents of Point Inspection 1 2 3 30 31

10

11

12

Method Listening Mechanical

of in- Observing Electrical

pection Testing Hydraulic

Symbols Results of inspection should be

filled in with symbols every day.

"√" perfect, "Δ“ abnormal, Treatment

"×" to be repaired, "⊗"already

repaired.

2. Contents and requirements of periodic maintenance

System normal operation greatly depends on periodic maintenance contents of

which are as the following:

2.1. Periodic fastening:

Pipe fittings and fasteners may be loosened due to the air trapped in the

hydraulic system during operation, direction change impact, pipe vibration,

system vibration etc. Without periodic fastening of them serious leakage may

occur and accident may be resulted in that may cause equipment damage and/or

personnel injury. Therefore, those bolts, nuts and fittings which are subjected

to impact and vibration must be fastened periodically.

For intermediate pressure equipment fittings, hose fittings, flange bolts, securing

bolts of cylinders and cove bolts, piston and stopper bolts, accumulator piping,

limit switches and stop bolts etc. must be fastened once a month. For

equipment with lower pressure they may be fastened once every three months.

In addition, tension for each bolt shall be even and reaches a certain torque.

2.2. Periodic replacement of seals

Leakage and suction are trouble which often happen in hydraulic systems. So

sealing is very important and there ate two categories of method to solve the

problem of sealing:

One is clearance sealing which is dependent on pressure drop, clearance between

two sliding surfaces, seal length and oil viscosity. Another one is sealing by

elastic material means rubber seals which depends on seal structure, material,

working pressure, application and installation etc. Currently horbunan and

polyester amine are used as elastic sealing material. After long period service

they may not only be degenerated but also be permanently deformed under high

pressure for a long period that results in losing seal property. Therefore

periodic replacement is necessary. Replacement of seals is a main work of

hydraulic system maintenance. A schedule

of seal replacement should be developed according to operation conditions of the

system and schedule should be included in the technical files maintained for the

appropriate equipment. According to seal rubber manufacture and sulfuration

procedure the seals have a service life of 5 years or so.

2.3. Periodic cleaning or replacing hydraulic components

After long period operation, in some components some dirt due to wear, replace

due to fatigue. Valves shall be cleaned once approximately needed to after

every 5 years operation. Cylinders must be cleaned once after every 8 years.

At the same time seals must be replaced. After reassemble of these components

their properties shall be measurement of normal operation.

2.4. Periodic clean or replacement of filter element

After a certain period of operation the solid foreign matters (such as dirt, scraps

etc.) may build-op on the filter element and stop it affecting normal oil flow. In

this case pump noise, temperature may operation of system will occur. It is

obvious that a schedule of cleaning and replacement of filter element must be

made in accordance with the operation conditions. Normally the filter should

be cleaned every 3 months. Filter clean schedule should be included in

maintained technical files.

2.5. Periodic cleaning of the reservoir

During long term operation contamination builds-op on the inside bottom of the

reservoir. The built-op foreign matters may be sucked by the pump into the

system and cause trouble. Special attention should be taken to the cleanliness

inside of the reservoir during replacement. Normally the reservoir should be

cleaned every 3 years or so.

2.6. Periodic cleaning of the piping

Oil contamination may be accumulated at pipe bending portions and some flow

passages of manifold the longer the system is operated the more contamination is

accumulated. This not only increases flow flushed with oil flow and may block

off

damping hole of some component that results in trouble. Therefore piping must

periodically be cleaning by two method:

2.6.1. Those pipes which can be removed such as manifold, hose etc. may be

cleaned after their removing.

2.6.2. Piping may be cleaned by oil circulating once every 8 years or so.

2.7. Periodic changing of oil

2.7.1. After 500~700 hours operation following adjustment and trial run the oil in the

system filled firstly must be completely changed. After that every 3000~5000

hours operation the oil should be changed. The above figures ate only for

supervision. Accurate time interval should be determine depending oil quality,

working temperature and other operation conditions. Attention should be paid

to that every time the oil is changed the bottom of the reservoir must be cleaned.

2.7.2. Oil changing process:

a) Drain all the oil in hot condition.

b) Oil in the reservoir should be drained off completely.

c) When clean the reservoir to the bottom should be paid special attention.

d) Clean or replace the filter and its element at he same time.

e) If the equipment is seriously contaminated or the oil is change to another type

then the equipment (system) should be flushed to clean by the new type of oil

before it is filled into.

Commission of Hydraulic System

Principle for hydraulic system commission:

Principle of Safety

Take measure for person safety

High pressure oil spray will danger person

Take measure for equipment safety

Too high pressure will damage rope

Other item should be know to make protection or take measure

Some adjusting screw can be out from main body to lead oil spray

Pressure should be from low to high as to check piping

Speed should be from slow to fast as to make check

Principle of Completeness

All parameter should be adjusted and ensure it at right value

All motor rotation should be right direction

All PLC control logic should be activated and in work station

All wiring should be right like NO, NC and earthing. Sometimes 0VDC earthing prohibited.

If abnormal noise happen, to check or vent and resolve completely.

Principle of Reliability

All value and control should be approved or tested to ensure it right.

System with problem should not stop work and not conceal it.

Principle of Logical Sequence

Before commissioning, a detail and considerable plan with one by one step should be

stipulated to ensure safety and completeness. Plan in hand, work half.

Make sure how much work to do and how many point to set and what pressure to set.

Principle of Cooperation

Before commissioning, all control involved should be ensure in hand to prevent unexpected

startup or action.

Commissioning may need electrical cooperation

Principle of Knowing how

Before commissioning, the working control logic and system working principle should be

know detailed

How to dispose every part on hydraulic system

Making Full Check before Commission

System OK, has unload

All suction line open

All piping connect

Oil filling

Electrical wiring

Accumulator pre-charge

Warning!

Misuse, wrong operation, insufficient handling or maintenance

endangers life or result in p equipments damage!

For making maintenance, working control and function should be known

first so able to analyze what is the problem and make assure that

under safe condition like unloading pressure oil in accumulator comple-

tely and in cylinder, shutting motor power off or crane CONTROL OFF

or EMERGENCY STOP, even mechanical locked. When do some step,

the result which can lead should have in idea for every step.

Following methods can be applied to resolve the fault:

Method of Inspecting, by looking, feeling

Method of Logical Analysis

Method of Exchanging Part

Method of Excluding

Method of Making Trial

Method of Knowledge Tree

Method of Measure by Device

The following faults can not include all faults that may meet in practice

days, more contents can be added to make it more complete and more

capable to direct working or more experienced by involved person. Every

problem should be coped with carefulness and more consideration even

taking further step to prevent it from happening again.

Troubleshooting for Rope Tension Hydraulic System

Symptoms or Problem Possible Causes Solution

Motor no power Check control system and wire

Pump pressure compensator setting low Re-set pump pressure

Motor rotary direction wrong Exchange wire to correct the direction

System no pressure System relief valve setting low Re-set pressure of relief valve

Shut-off valve open let pump unload Close shut-off valve

Cylinder seal damage to enlarge its Check inner leakage and Change seals if

inner leakage necessary

Boom relief valve setting too high Check boom relief valve setting pressure

Solenoid coil damage Check solenoid coil

high pressure signal

Pressure relay setting too low Check pressure point setting on pressure

when boom run

switch which give high pressure signal

The rope is winded Check

tensioning low pressure Pump is not work or destroyed Check

signal Throttle valve 53.1 is open Close it

tensioning cylinder Valve have inner leakage Check and change

automatically retract Cylinders have inner leakage Check seal and change

when control off

The setting pressure of the pressure Adjust the setting pressure

switch (lower point) is not proper

Motor start frequently

Throttle valve 53.1 or 53.2 is open Close it

Valve or cylinder have inner leakage Check

Motor start frequently Check

Overheating signal

Relief valve work Check

Troubleshooting for wheel brake Hydraulic System

Symptoms or Problem Possible Causes Solution

Motor no power Check control system and wire

The pump is destroyed Check and change

System no pressure Motor rotary direction wrong Exchange wire to correct the direction

Throttle valve 8 is open Close it

The setting pressure of the pressure Adjust the setting pressure

switch is not proper

Throttle valve 8 is open Close it

Motor start frequently Throttle valve 9 is close Open it

Accumulator is not work or destroyed Check

Exterior oil leakage Check

Valve have inner leakage Check

The higher setting pressure of the Adjust the setting pressure

pressure switch is not proper

Throttle valve 8 is open Close it

The setting pressure of relief valve is Adjust

Motor run too long

higher

The pump is destroyed Check and change

Exterior oil leakage Check

Valve have inner leakage Check

Valve have inner leakage Check

The setting pressure of relief valve is Adjust

Over temperature signal lower

Exterior oil leakage Check

Throttle valve 08 is open Close it

Exterior oil leakage Check

Low level fault The level is lower in fact Fill oil

The float switch is destroyed Check and change

Motor run too long

The coil and plug of the solenoid valve

The releasing time is too

is destroyed

long

The limit switch of the brake can’t

work

Troubleshooting for boom&hoist disc brake Hydraulic System

Symptoms or Problem Possible Causes Solution

Motor no power Check control system and wire

The pump is destroyed Check and change

System no pressure Motor rotary direction wrong Exchange wire to correct the direction

Throttle valve 8.1 is open Close it

The setting pressure of the pressure Adjust the setting pressure

switch is not proper

Throttle valve 8.1 is open Close it

Motor start frequently

Accumulator is not work or destroyed Check

Exterior oil leakage Check

Valve have inner leakage Check

The higher setting pressure of the Adjust the setting pressure

pressure switch is not proper

Throttle valve 8.1 is open Close it

The setting pressure of relief valve is Adjust

Motor run too long

higher

The pump is destroyed Check and change

Exterior oil leakage Check

Valve have inner leakage Check

Valve have inner leakage Check

The setting pressure of relief valve is Adjust

Over temperature signal lower

Exterior oil leakage Check

Throttle valve 8.1 is open Close it

Exterior oil leakage Check

Low level fault The level is lower in fact Fill oil

The float switch is destroyed Check and change

Motor run too long

The coil and plug of the solenoid valve

The releasing time is too

is destroyed

long

The limit switch of the brake can’t

work

MAINTENANCE MANUAL

APMT Tangiers MED 2,MOROCCO

TWELVE QUAYSIDE CONTAINER CRANES

____________________________________________________________________

SHANGHAI ZHENHUA HEAVY INDUSTRIES CO.,LTD

Address: 3261 DONGFANG ROAD, PUDONG NEW DISTRICT, SHANGHAI, CHINA

Postcode: 200125

Tel: 001-86-21-58396666

Fax: 001-86-21-58399555

Website: http://www.zpmc.com

____________________________________________________________________

You might also like

- Dkyc 320 31.5d Hydraulic Power Control UnitNo ratings yetDkyc 320 31.5d Hydraulic Power Control Unit30 pages

- Operating Manual For Climbing Formwork Hydraulic SystemNo ratings yetOperating Manual For Climbing Formwork Hydraulic System22 pages

- Hydraulic Surface Grinder Operator ManualNo ratings yetHydraulic Surface Grinder Operator Manual16 pages

- SX07 Manual 72116209 From Batch 211001-2022.02No ratings yetSX07 Manual 72116209 From Batch 211001-2022.0232 pages

- Autonomous Training Material Step 4 - HydraulicsNo ratings yetAutonomous Training Material Step 4 - Hydraulics66 pages

- Operation Manual: The Fifth Edition Edited JULY 01, 1997 FOR TM6X+T6C SequenceNo ratings yetOperation Manual: The Fifth Edition Edited JULY 01, 1997 FOR TM6X+T6C Sequence165 pages

- Piston Pump (Main) - Test: SMCS - 5070-081100% (2)Piston Pump (Main) - Test: SMCS - 5070-08116 pages

- Operator & Maintenance Manual - Hydra 14 EX (25402)100% (3)Operator & Maintenance Manual - Hydra 14 EX (25402)100 pages

- Comparison of k ε and RNG k ε Turbulent Models for Estimation of Velocity Profiles along the Hydraulic Jump on Corrugated BeNo ratings yetComparison of k ε and RNG k ε Turbulent Models for Estimation of Velocity Profiles along the Hydraulic Jump on Corrugated Be6 pages

- Bosserman2008control of Hydraulic TransientsNo ratings yetBosserman2008control of Hydraulic Transients26 pages

- The Operation of Pressure Safety DevicesNo ratings yetThe Operation of Pressure Safety Devices4 pages

- Orifice Plate Design and Calculation GuideNo ratings yetOrifice Plate Design and Calculation Guide8 pages

- Pump 2 - Data - Sheet - 32X32 - FSS2FC - 6 - 1.5 - HNo ratings yetPump 2 - Data - Sheet - 32X32 - FSS2FC - 6 - 1.5 - H4 pages

- Measuring Total Head with Bernoulli EquationNo ratings yetMeasuring Total Head with Bernoulli Equation5 pages

- Metering Pump Prominent Pneumados: Instruction ManualNo ratings yetMetering Pump Prominent Pneumados: Instruction Manual34 pages

- Wind Load Reaction Force Due To Wind Action From Stack Acting On The Fan DeckNo ratings yetWind Load Reaction Force Due To Wind Action From Stack Acting On The Fan Deck3 pages

- HM 150.04 Centrifugal Pump Gunt 551 PDF - 1 - en GB100% (1)HM 150.04 Centrifugal Pump Gunt 551 PDF - 1 - en GB3 pages

- Micro-Bubble Generator Performance StudyNo ratings yetMicro-Bubble Generator Performance Study10 pages