Civil Engineering Smart Scan - Removed - Compressed

Uploaded by

rushavanagCivil Engineering Smart Scan - Removed - Compressed

Uploaded by

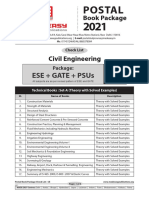

rushavanagCivil Engineering

AE, JE, State PSC, ESE, PSU's & Other Competitive Exams

SSC-JE (Pre & Mains) RRB-JE UPSSSC-JE UPPSC-AE :

NHPC-JE UKPSC AE BPSC AE CGPSC AE MPPSC AE RPSC AE DMRC JE

LMRC JE JMRC JE BMRC JE DSSSB JE/AE SJVN JE UKSSSC JE RSMSSB JE

HPSSC JE MPPEB SUB ENGINEER DDA-AE/JE HSSC JE JSSC JE BSSC JE

DRDO JE ISRO CGPEB SUB ENGINEER UPPCL AE/JE UPRVUNL AE/JE JVUNL

JE SAIL JE GAIL JE BHEL JE NTPC JE DFCCIL COAL INDIA LTD. JE

WBPSC AE TAMILNADU TRB TNPSC AE J&K PSC AE SIKKIM PSC AE OPSC

AE MPSC AE GUJARAT PSC AE PTCUL

Chief Editor

A.K. Mahajan

Compiled & Written by

Er. Maneesh Kr. Yadav (Highway Engineer Delhi)

Er. Pradeep Kr. Gupta, Er. Anees kr. Verma,

Computer Graphics by

Bal Krishna, Charan Singh, Arjun Prasad & Pankaj Kushwaha

Editorial Office

12, Church Lane Prayagraj-211002

Mob. : 9415650134

Email : [email protected]

website : www.yctbooks.com / www.yctfastbook.com

© All rights reserved with Publisher

Publisher Declaration

Edited and Published by A.K. Mahajan for YCT Publications Pvt. Ltd.

and printed by EXAM PREPARATION APP In order to Publish the E-book,

full care has been taken by the Editor and the Publisher,

still your suggestions and queries are welcomed. Rs. : 595/-

In the event of any dispute, the judicial area will be Prayagraj.

Index

Appendix .............................................................................................................................................................................. 17-20

Amendment (IS 456 : 2000) 2013 & 2019 .......................................................................................................... 21-30

Building Material ------------------------------------------------------------------------------------------31-67

1. Building Rock and Stone ..............................................................................................................32-37

2. Bricks ............................................................................................................................................38-44

3. Lime ..............................................................................................................................................45-46

4. Cement ..........................................................................................................................................47-54

5. Timber ............................................................................................................................................55-60

6. Paint ...............................................................................................................................................61-65

7. Ferrous and Non-Ferrous Material ................................................................................................66-66

8. Glass ...............................................................................................................................................67-67

Building Construction and Maintenance Engineering ..............................................................68-107

1. Introduction ...................................................................................................................................69-72

2. Masonry ........................................................................................................................................73-81

3. Lintel and Arches ...........................................................................................................................82-83

4. Stairs .............................................................................................................................................84-86

5. Scaffolding and Shoring.................................................................................................................87-90

6. Door, Window & Ventilators .........................................................................................................91-96

7. Roofs and Roof covering .............................................................................................................97-102

8. Surface Finishing .......................................................................................................................103-104

9. Construction Equipment ............................................................................................................105-107

Concrete Technology ................................................................................................................. 108-144

1. Introduction ................................................................................................................................109-115

2. Property of Concrete ..................................................................................................................116-120

3. Water Cement Ratio ...................................................................................................................121-122

4. Formwork ...................................................................................................................................123-124

5. Proportioning of Concrete mixes ...............................................................................................125-128

6. Concreting Operations ...............................................................................................................129-135

7. Concreting in Adverse Conditions .............................................................................................136-136

8. Durability of Concrete ...............................................................................................................137-139

9. Repair and Maintenance of Concrete .........................................................................................140-140

10. Special Types of Concrete .......................................................................................................141-143

11. Miscellaneous...........................................................................................................................144-144

Earthquake Engineering and Disaster Management ..............................................................145-151

Surveying Engineering ...............................................................................................................152-207

Surveying I ...............................................................................................................................152-181

1. Introduction of Surveying ..........................................................................................................153-156

2. Chain Surveying.........................................................................................................................157-164

3. Compass Surveying....................................................................................................................165-170

4. Levelling ....................................................................................................................................171-177

5. Calculation of Area ....................................................................................................................178-179

6. Minor Instrument .......................................................................................................................180-180

7. Conventional sign ......................................................................................................................181-181

Surveying II ............................................................................................................................182-197

1. Plane Table Surveying ...............................................................................................................182-185

2. Contouring .................................................................................................................................186-189

2

3. Theodolite ..................................................................................................................................190-193

4. Tacheometric Surveying ............................................................................................................193-195

5. Curve ..........................................................................................................................................196-197

Advance Survey ......................................................................................................................198-207

1. Modern Field Survey System.....................................................................................................198-200

2. Photogrammetric or Areal survey ..............................................................................................201-204

3. Field Astronomy ........................................................................................................................205-207

Estimating Costing & Valuation ............................................................................................. 208-224

1. Introduction ................................................................................................................................209-211

2. Unit of Measurement and Payment ............................................................................................212-214

3. Methods of Building Estimate ...................................................................................................215-216

4. Earth work in road and canal .....................................................................................................217-218

5. Analysis of Rates .......................................................................................................................219-221

6. Valuation ....................................................................................................................................222-224

Engineering Drawing..................................................................................................................225-238

Auto Cad ..................................................................................................................................... 239-243

Construction Management, Accounts & Entrepreneurship Development (CMAED) ........ 244-254

1. Construction Management, Planning and Scheduling ...............................................................245-251

2. Organization ...............................................................................................................................252-252

3. Miscellaneous.............................................................................................................................253-254

Reinforced Cement Concrete....................................................................................................255-287

1. Introduction ................................................................................................................................256-258

2. Working stress method (WSM) .................................................................................................259-262

3. Doubly Reinforced Beam...........................................................................................................263-263

4. Shear and Bond Strengths ..........................................................................................................264-267

5. Reinforced Concrete Slab ..........................................................................................................268-272

6. T-Beam or Flanged Beams ........................................................................................................273-275

7. Columns and Footing .................................................................................................................276-279

8. Retaining Walls ..........................................................................................................................280-282

9. Limit State Method ....................................................................................................................283-285

10. Prestressed Concrete ................................................................................................................286-287

Applied Mechanics .................................................................................................................... 288-295

Strength of Material ................................................................................................................. 296-330

1. Simple stress and strain ..............................................................................................................297-302

2. Principal Stress and Strain .........................................................................................................303-305

3. Strain Energy..............................................................................................................................306-306

4. Theories of Failure .....................................................................................................................307-308

5. Shear Force and Bending Moment.............................................................................................309-312

6. Direct stress and bending stress .................................................................................................313-313

7. Slope and Deflection of Beam ...................................................................................................314-316

8. Bending Stress in Beams............................................................................................................317-318

9. Shear Stresses in Beams and Shear Centre ................................................................................319-320

10. Column and Strut .....................................................................................................................321-322

11. Torsion .....................................................................................................................................323-324

12. Springs .....................................................................................................................................325-326

13. Pressure vessels ........................................................................................................................327-328

14. Centre of gravity and moment of Inertia ..................................................................................328-330

Design of Steel Structure ........................................................................................................... 331-362

1. Introduction ................................................................................................................................332-333

2. Structural Fasteners ....................................................................................................................334-342

3

3. Tension Member ........................................................................................................................343-345

4. Compression Member ................................................................................................................346-349

5. Beam & Gantry Girder ...............................................................................................................350-352

6. Eccentric Connections................................................................................................................353-354

7. Column Bases ............................................................................................................................355-356

8. Plate Girder ................................................................................................................................357-359

9. Plastic Analysis ..........................................................................................................................360-362

Structural Analysis .................................................................................................................... 363-384

1. Determinacy and Indeterminacy ................................................................................................364-366

2. Truss ...........................................................................................................................................367-368

3. Influence Line Diagram .............................................................................................................369-372

4. Suspension Bridge, Cables and Arches......................................................................................373-378

5. Methods of Structural Analysis..................................................................................................379-382

6. Matrix Method ...........................................................................................................................383-384

Fluid Mechanics ......................................................................................................................... 385-434

1. Properties of Fluids ....................................................................................................................386-389

2. Pressure and its Measurement ....................................................................................................390-392

3. Hydrostatic forces on surfaces ...................................................................................................393-393

4. Buoyancy and Floatation ...........................................................................................................394-395

5. Kinematics of Flow ....................................................................................................................396-400

6. Fluid Dynamics ..........................................................................................................................401-403

7. Orifices and Mouthpieces ..........................................................................................................404-405

8. Notches and Weirs .....................................................................................................................406-408

9. Viscous Flow..............................................................................................................................409-409

10. Turbulent flow..........................................................................................................................410-411

11. Flow Through Pipes .................................................................................................................412-413

12. Dimensional and Model Analysis ............................................................................................414-415

13. Boundary Layer Theory ...........................................................................................................416-419

14. Open Channel Flow .................................................................................................................420-425

15. Impact of Jets and Jet Propulsion .............................................................................................426-427

16. Turbine and Pumps ..................................................................................................................428-434

Irrigation Engineering............................................................................................................... 435-472

1. Irrigation Technique and quality of irrigation water ..................................................................436-438

2. Water requirement of crops........................................................................................................439-442

3. Canal irrigation System..............................................................................................................443-445

4. Design of Irrigation Channel......................................................................................................446-448

5. Construction and Maintenance of Canals ..................................................................................449-451

6. Diversion Headworks .................................................................................................................452-454

7. River Training Works ................................................................................................................455-458

8. Cross Drainage work..................................................................................................................458-459

9. Design and construction of gravity dam ....................................................................................460-466

10. Water Logging and Drainage ...................................................................................................467-468

11. Ground Water...........................................................................................................................469-472

Engineering Hydrology.............................................................................................................. 473-491

1. Introduction ................................................................................................................................474-475

2. Precipitation ...............................................................................................................................476-481

3. Abstraction from precipitation & Stream Flow Measurement ...................................................482-485

4. Runoff and Hydrograph .............................................................................................................486-488

5. Floods and Flood Routing ..........................................................................................................489-491

4

Environmental Engineering .......................................................................................................492-538

Water Supply Engineering .....................................................................................................492-515

1. Water Demand ...........................................................................................................................493-496

2. Water Quality Parameter ............................................................................................................497-503

3. Treatment of Water ....................................................................................................................504-509

4. Disinfection and Softening of Water..........................................................................................510-512

5. Distribution System....................................................................................................................513-515

Sanitary Engineering ..............................................................................................................516-538

1. Public Sanitation quantity of sewage .........................................................................................516-517

2. Sewerage Systems and sewer .....................................................................................................518-520

3. Building Drainage and plumbing ...............................................................................................521-522

4. Characteristics of Waste Water or Sewage ................................................................................523-525

5. Sewage Treatment ......................................................................................................................525-531

6. Disposal of Waste Water and Sewage .......................................................................................532-533

7. Pollution (Air and Noise) ...........................................................................................................534-538

Soil Mechanics............................................................................................................................ 539-594

1. Origin of soil ..............................................................................................................................540-540

2. Basic definition & simple test of soil .........................................................................................541-544

3. Index properties of Soil ..............................................................................................................545-550

4. Soil classification .......................................................................................................................551-553

5. Soil Structure and Clay Mineralogy...........................................................................................554-555

6. Effective and Neutral Stresses ..................................................................................................556-556

7. Soil Hydraulic ............................................................................................................................557-561

8. Compaction ................................................................................................................................562-564

9. Consolidation .............................................................................................................................565-568

10. Stability of Slope......................................................................................................................569-571

11. Earth Pressure Theory ..............................................................................................................572-574

12. Stress Distribution in Soil ........................................................................................................575-577

13. Shear Strength of Soil ..............................................................................................................578-581

14. Foundation ...............................................................................................................................582-587

15. Bearing Capacity of Shallow Foundation ................................................................................588-592

16. Soil Exploration .......................................................................................................................593-594

Highway Engineering ................................................................................................................ 595-627

1. Highway Development and Planning.........................................................................................596-598

2. Geometric Design of Highways .................................................................................................599-608

3. Traffic Engineering ....................................................................................................................609-618

4. Highway Materials .....................................................................................................................619-622

5. Pavement Design........................................................................................................................623-627

Railway Engineering ................................................................................................................. 628-645

1. Introduction ................................................................................................................................629-630

2. Rail Joints, Defect and Track Stresses .......................................................................................631-634

3. Geometric Design of Track ........................................................................................................635-637

4. Point and Crossing .....................................................................................................................638-639

5. Sleeper, Ballast, Fastening and Fixtures ....................................................................................640-642

6. Railway Signal and Station Yard ...............................................................................................643-645

Bridge, Tunnel and Airport Engineering ................................................................................ 646-656

1. Bridge Engineering ....................................................................................................................647-649

2. Tunnel Engineering ....................................................................................................................650-652

3. Airport Engineering ...................................................................................................................653-656

5

10. 5.2.3.2 Concrete containing mineral admixtures may exhibit and increase in plastic shrinkage cracking

because of its low bleeding characteristics. The problem may be avoided by ensuring that such

concrete is protected against drying, both during and after finishing.

(after Amendment No.5 July 2019)

11. 5.2.3.3 Some other properties of concrete such as modulus of elasticity, tensile strength, creep and

shrinkage are not likely to be significantly different. For design purposes, it will be sufficiently

accurate to adopt the same values as those used for concrete made with ordinary Portland cement

alone.

(after Amendment No.5 July 2019)

12. 5.2.3.4 Mixes that contain very fine mineral admixtures such as silica fume, can be sticky and difficult to

finish.

(after Amendment No.5 July 2019)

13. 5.2.3.5 Concrete made using blended cements such as Portland Pozzolana cement and Portland slag cement

shall also adhere to 5.2.3.1, 5.2.3.2 and 5.2.3.3.

(after Amendment No.5 July 2019)

14. 11.0

Formwork Type Formwork Minimum Type of minimum Period

Period Before Formwork Before

Striking for For concrete

Formwork concrete Made Using

(a) Vertical formwork to 16–24 h made Cement

columns, walls, RRB SSE using OPC Other than

Secundrabad-01-09-

beams OPC or

2015 (Shift-I)

Using

(b) Soffit formwork to slabs 3 days

(Props to be Mineral

refixed immediately after Admixtures

removal of formwork) Like Fly

Ash and

(c) Soffit formwork to beams 7 days

(Props to be refixed slag

immediately after i) Vertical 16–24h 16–24 h

removal of formwork) formwork

(d) Props to slabs to

columns,

(i) Spanning up to 4.5 m 7 days

UPPCL JE 02-01-

walls,

2021(Shift-I) beams

SSB HP-18-11-2018 ii) Soffit 3 days 7 days

RRB SSE formwork

Secundrabad-01-09-

2015 (Shift-II) to slabs

(ii) Spanning over 4.5 m 14 days (Props to

LMRC AE-2017 be refixed

(Shift-I) immediate

(e) Props to beams and arches ly after

(i) Spanning up to 6 m 14 days removal of

RRB SSE Online-01- formwork)

09-2015 (Shift-II)

iii) Soffit 7 days 10 days

(ii) Spanning over 6 m 21 days form work

to beams

(props to

be refixed

immediate

ly after

removal of

formwork)

iv) Props to

slabs: 7 days 10 days

1) Spanning 14 days 14 days

up to 4.5

m

2) spanning

over 4.5 m

Civil Engineering Smart Scan 22 YCT

6. Table 2 –

Grades of Group Grade Specified Group Grade Specified

Concrete designation characteristic designation characteristic

compressive strength compressive

of 150 mm cube at 28 strength of 150

days in N/mm2 mm cube at 28

UPSSSC JE 16-4-2022 days in N/mm2

M 10 10 UPSSSC JE 16-4-2022

Ordinary M 15 15 M 10 10

concrete SSC JE-03-03-2017 Ordinary M 15 15

(Even.) concrete Andman&Nicobar

M 20 20 APWD JE Civil 27-

NBCC JE-2018 (Morn.) 7-2019

M 25 25 SSC JE-03-03-2017

M 30 30 (Even.)

M 35 35 M 20 20

Standard KPSC AE Civil

M 40 40 26-2-2023

Concrete

M 45 45 NBCC JE-2018

M 50 50 (Morn.)

M 55 55 M 25 25

M 60 60 Andman & Nicobar

Plan.Asst. 6-3-

M 65 65

High strength Standard 2023 (Shift-I)

M 70 70

Concrete Concrete M 30 30

M 75 75

M 35 35

M 80 80

M 40 40

KPSC AE

Note- Civil

(1) In the designation of concrete mix M refers to 26-2-2023

the mix and the number to the specified M 45 45

compressive strength of 150 mm size cube at 28 M 50 50

days, expressed in N/mm2

M 55 55

(2) For concrete of compressive strength greater

M 60 60

than M 55, design parameters given in the

standard may not be applicable and the value M 65 65

may be obtained from specialized literature and M 70 70

experimenal results. High M 75 75

strength M 80 80

Concrete

M 85 85

M 90 90

M 100 100

In this amendment, Classification of

Concrete has been changed. M60Gr. has

been shifted to Standard concrete and from

Grades M85 to M100 are added to High

strength concretes. In note to M55 is

replaced with M60.

7. 8.1 A durable concrete is one that performs A durable concrete is one that performs

General satisfactorily in the working environment during its satisfactorily in the working environment during

anticipated exposure conditions during service. The its anticipated exposure conditions during

materials and mix proportions specified and used service life. The materials and mix proportions

should be such as to maintain its integrity and, if specified and used should be such as to maintain

applicable, to protect embedded metal from its integrity and, if applicable, to protect

corrosion. embedded metal from corrosion.

8. NOTES to Cement content prescribed in this table is Cement content prescribed in this table is

Table 5 irrespective of the grades of cement and it is irrespective of grades and types of cement

Minimum inclusive of additions mentioned in 5.2. The and is inclusive of mineral admixtures

Cement additions such as fly ash or ground granulated blast mentioned in 5.2. The mineral admixtures

Content, furnace slag may be taken into account in the such as fly ash or ground granulated blast

Maximum concrete composition with respect to the cement furnace slag shall be taken into account in

Civil Engineering Smart Scan 24 YCT

14 Table 8

. Assumed

Standard

Deviation

NOTES -

The above values correspond to the site control NOTES -

having proper storage of cement; weight batching 1. The above values correspond to the site

of al materials; controlled addition of water; control having proper storage of cement;

regular checking of all materials, aggregate weight batching of al materials;

gradings and moisture content; and periodical controlled addition of water; regular

cheacking of workability and strength. Where there checking of All materials, aggregate

is deviation from the above the values given in the gradings and moisture content; and

above table shall be increased by IN/mm2. periodical cheacking of workability and

strength. Where there is deviation from

the above the values given in the above

table shall be increased by 1N/mm2

2. for grade above M60, the standard

deviation shall be established by actual

trials based on assumed proportion,

before finalizing the mix.

3. In this amendment, M55 and M60 has

been added in the amended version to the

Grade of Concrete. Also note 2 is added

15 10.2 To avoid confusion and error in batching, To avoid confusion and error in batching,

Batching consideration should be given to using the smallest consideration should be given to using the

practical number of different concrete mixes on any smallest practical number of different

site or in any one plant. In batching concrete, the concrete mixes on any site or in any one

quantity of both cement and aggregate shall be plant. In batching concrete, the quantity of

determined by mass; admixture, if solid, by mass; both cement and aggregate shall be

liquid admixture may however be measured in determined by mass; admixture, if solid, by

volume or mass; water shall be weighed or mass; liquid admixture may however be

measured by volume in a calibrated tank (see also IS measured in volume or mass; water shall be

4925). Ready-mixed concrete supplied by ready- weighed or measured by volume in a

mixed concrete plant shall be preferred. For large calibrated tank (see also IS 4925).

and medium project sites the concrete shall be For large and medium project sites, the

sourced from ready mixed concrete plants or from concrete shall be sourced from Ready mixed

on site or off site batching and mixing plants (see IS concrete plants or from captive on site or off

4926). site automatic batching and mixing plants.

The concrete produced and supplied by

ready-mixed concrete plants shall be in

accordance with IS 4926. In case of

concrete from captive on site or off site

automatic batching and mixing plants,

similar quality control shall be followed.

16 10.2.1 Except where it can be shown to the satisfaction of The grading of aggregate shall be controlled

the engineer-in-charge that supply of properly by obtaining the coarse aggregate in

graded aggregate of uniform quality can be different sizes and blending them in right

maintained over a period of work, the grading of proportions, the different sizes being

aggregate should be controlled by obtaining the stocked in separate stock piles. The material

coarse aggregate in different sizes and blending should be stock-piled for several hours

them in the right proportions when required, the preferably a day before use. The grading of

different sizes being stocked in separate stock-piles. coarse and fine aggregate should be checked

The material should be stock-piled for several hours as frequently as possible, the frequency for a

preferably a day before use. The grading of coarse given job being determined by the engineer-

and fine aggregate should be checked as frequently in charge to ensure that the specified

as possible, the frequency for a given job being grading is maintained.

determined by the engineer-in charge to ensure that

the specified grading is maintained.

Civil Engineering Smart Scan 26 YCT

1. Building Rock and Stone ......................................................................................................... 32

2. Bricks ....................................................................................................................................... 38

3. Lime ......................................................................................................................................... 45

4. Cement ..................................................................................................................................... 47

5. Timber....................................................................................................................................... 55

6. Paint .......................................................................................................................................... 61

7. Ferrous and Non-Ferrous Material ........................................................................................... 66

8. Glass.......................................................................................................................................... 67

Trend Analysis of Questions topicwise from SSC JE/ ESE/ State PSC & other exam

Civil Engineering Smart Scan 31 YCT

01.

BUILDING ROCK & STONE

Introduction- 4. Luster-

Petrology deals with the study of origin and GES 2019

characteristics of rock. It is the shining of the surface of mineral under

Rate of increase of temperature below the earth reflection of light. It is classified as glassy, greasy,

surface is 150-300 C/km or 10C for every 32 meter. pearly, dull, resinous, silky and metallic.

The molten mass present at deep depth from the 5. Texture- It indicate the coarseness/arrangement of

earth surface is known as magma. It is the part of the grains of mineral.

upper mantle. When magma comes above the earth ❑ CLASSIFICATION OF ROCKS-

surface then it is known as lava.

The major composition of magma is - Feldspar,

Quartz, mica.

Rock Forming Minerals-

UPMRC AM 2023, SSC JE 2018,UPMRC JE 2015

Calcite, Dolomite, Feldspar, Quartz, Mica, Gypsum,

Amphibole, olivine.

Gypsum and Dolomite are rock and minerals both.

Properties of Mineral-

1. Cleavage-

It is the measure of the capability of minerals to split

along certain planes parallel to the crystal faces.

Types of cleavage seen in minerals are basal,

prismatic, cubic, octahedral.

2. Hardness-

Hardness is the resistance of a smooth surface

against abrasion or scratching. It is measure on

Moh's scale.

Minerals Hardness on Description

Moh's scale

Talc 1 Scratched by the finger

Gypsum 2 nail

Calcite 3 Scratched by knife

Fluorite 4

Apatite 5

Feldspar/ 6 Scarcely scratched by

Orthoclase knife

Quartz 7

Topaz 8 Not scratched by

Corundum/ 9 knife

Sapphire

Diamond 10

3. Streak-

UPPSC AE 2020

It is the color of mineral in the powder form.

Civil Engineering Smart Scan 32 YCT

Geological Classification- properties and new types of rock formed. These new

CHB JE 2023, UPRVUNL JE 2022, MHWRD JE 2022,

types of rock are called metamorphic rock. The

UPPCL JE 2022, SSC JE 2022, NWDA JE 2021

resultant mass may have a foliated structure.

Igneous/Primary/Unstratified/Eruptive rock- Parent Metamorphic

Rock form

SSC JE 2022, DSSSB JE 2019

These rocks are formed by the cooling of molten Granite, Syenite Gneiss

magma forced up through crack in the earth crust. Dolerite, Basalt, Laterite Schist

These rocks have crystalline structure and hard, Dolomite, Lime stone, Marl Marble

durable, massive and stronger than other rocks. UKPSC JE 2022 PAPER-II

Ex. Basalt, Trap, Syenite, Diorite etc. Mudstone, Shale Slate

Igneous rocks are following two types– Sand stone Quartzite

1. Extrusive/Volcanic/Effusive Rock- Gabbro Serpentine

These rocks are formed when the molten magma is

Bituminous coal Graphite

cooling and freezing above or at the earth's surface.

These rocks have extremely fine grained crystalline Lignite coal Anthracite

structure. i). The texture of igneous rock is depends upon

Ex. Basalt, Trap, Andesite, Dolomite, Dacite, the rate of cooling of magma.

Rhyolite, Pumice, Tuff, Scoria etc. ii). Texture of igneous rock and sedimentary rock

2. Intrusive Rock- is crystalline and granular respectively.

GPSC AE 2018 Chemical Classification-

Due to cooling of magma at a deep/considerable DDA JE 2023, UPPCL JE 2022

depth from earth's surface. DSSSB JE (Tier-I) 2022, PSTCL AE 2021

These are following two types– Types of rock Example

(i) Plutonic Rock- Siliceous Rock- Granite, Syenite, Basalt,

UPRVUNL JE 2022, DSSSB JE (Tier-I) 2022 Major constituent is silica Trap, Sand stone,

Mizoram PSC 2021, UPMRC JE 2018 (SiO2). It is very hard and Quartzite, Gneiss etc.

These rocks are formed when the molten magma durable.

freezing at the deep depth from the earth surface. Calcareous Rock- Gypsum, Lime stone,

These rocks have coarse grained crystalline Major constituent is lime. Dolomite, Marble etc.

structure.

Ex. Granite, Syenite, Gabbro, Pegmatite, Diorite. Argillaceous Rock- Shale, Slate, Laterite,

(ii) Hypabyssal Rock- Major constituent is clay Kaolin etc.

GPSC AE 2021, DSSSB JE 2019 (Al2O3). It is hard and

These rocks are formed when molten magma is brittle in nature.

solidifies at the shallow depth from the earth surface. Physical/Petrological Classification-

These rocks have fine grained crystalline structure. 1. Stratified Rock-

Ex. Dolerite, Diorite JSSC JE 2022, RSMSSB JE 2022, NWDA JE 2021

SSC JE 2020, DSSSB JE 2019

Sedimentary/Aqueous/Stratified Rock-

These rocks show distinct layers along which the

MHWRD JE 2022, SSC JE 2022

rocks can be split.

UKPSC AE 2022, GPSC AE 2021, NWDA JE 2021

Ex. All sedimentary rock like sand stone, lime stone

BSPHCL JE 2019, DDA JE 2018, SSC JE 2018

marble, shale, slate etc.

These rock are formed by the accumulation or

2. Un-stratified Rock-

regular deposition of mineral or organic particles at

Do not show any stratification and can't be easily

earth surface followed by cementation these rocks

split into thin layers.

have granular structure.

Ex. All igneous rocks like granite, syenite, basalt,

Ex. Sand stone, Lime stone, Gypsum, Laterite, trap etc.

shale, Kankar etc.

3. Foliated Rock-

Metamorphic Rock- MHWRD JE 2022, NHPC JE 2022, DSSSB JE 2019

ESE 2022, MHWRD JE 2022, MHADA JE 2022 These rock can be split up only in a definite

JSSC JE 2022 DSSSB JE (Tier-I) 2022, RSMSSB JE 2021 direction. Most of the metamorphic rocks have

Due to high pressure and temperature igneous and foliated structure, except quartzite, serpentine and

sedimentary rocks have changed their physical marble.

Civil Engineering Smart Scan 33 YCT

On the basis of minerals available- Basalt Marine work, Rubble masonry.

Types of rock Example Kankar Manufacture of Hydraulic lime.

Monomineralic Rock- Gypsum, Marble, Gneiss Rough stone masonry work,

These rocks are formed Quartzite etc. (metamorphic) stone pitching and road metal.

by only one types of Sand stone In the form of flag stone, for

mineral. paving, tile stone for roofing,

Polymineralic Rock- Granite, Gneiss, Basalt, natural stone for ornamental

These rocks are formed Lime stone, Sand stone, work and grit for heavy

by two or more than two Trap, Basalt, Shale, Slate engineering work.

types of minerals. etc. Stiffness of Rock-

Descriptive Modulus of

Key Points Elasticity (kg/cm2)

■ When heated to 205 ºC, pure gypsum loses its Very Stiff Rock 8 × 105 − 16 × 105

luster and its specific gravity is increased

from_____to_____due to the loss of water of Stiff Rock 4 × 105 − 8 × 105

crystallization– 2.3 ; 2.95 Medium Stiff Rock 2 × 105 − 4 × 105

■ 24 – Hours water absorption of granite should not Less Stiff Rock 1 × 105 − 2 × 105

be greater than– 1%

■ If stone quarrying is done by the blasting method Yielding Rock 0.5 × 105 − 1× 105

with a length of line of least resistance of 2 m, the High Yielding Rock 0.25 × 105 − 0.5 × 105

rough estimate of gun powder required is– 500 g

■ The metamorphe stone that has porous and spngy Quarrying of stone-

structure, can be easily quarried in blocks contains Quarry-

high percentage of iorn–oxide and available in The place at which stone is obtained is known as

different colours– Laterite quarry.

■ The number of minerals arranged in the Moh's Quarrying-

scale of hardness is– 10 UPSSC JE 2022, SSC JE 2022

■ The aggregates in an example of crystalline The process under which stone is obtained from rock

surface texture– Gabbro is known as quarrying.

■ Specific gravity for most of the building stones lies Quarry Sap-

between– 2.5 to 3.0 The moisture present in newly quarried stone is

called quarry sap.

On the basis of Percentage of silica

❖ Tools used in Quarrying of stone-

available in rock-

1. Acidic Rock- Name of Tools Use

Silica is greater than 70%- 80%. Priming Needle To make space for fuse

Ex. Granite, Syenite, Rhyolite, Andesite etc. Jumper To make hole

2. Basic Rock- Dipper For making deep hole

Silica is less than 60%. Scraping spoon For cleaning hole

Ex. Basalt, Gabbro, Dolomite, Dolerite etc. Tamping Rod For tamping of explosive

Use of Various Types of stone- length = 600mm, dia. = 16mm

UKPSC AE 2021, SSC JE 2019

Hammer To penetrate the wedge in rock

Stone Use hole

Granite Railway ballast, roofing, Wedge For split the rock slab

abutment pier sea walls, and Crow bar To removed the wedge

light house.

It is costly so not used in ❖ Methods of Quarrying-

UPSSSC JE 2021, PSTCL AE 2021, KPSC AE 2018

general work.

Marble Ornamental work, monuments, Method Suitability Example

flooring. Wedging Costly, soft and Sand stone,

stratified rock. Lime stone,

Lime Stone Manufacture of cement.

Laterite, Marble

Slate Flooring, Roofing for ordinary and Slate etc.

slab, damp proofing. Heating Those rock whose Granite, gneiss

Quartzite Retaining wall, rubble masonry thermal expansion is etc.

It has best weather resistance. very low.

Civil Engineering Smart Scan 34 YCT

Digging To get stone at a Serpentine, Dressing of Stone-

small scale. Gypsum, NBCC JE 2017

Aterite. The action which is done on the rough surface of

Channeling Obtaining stone in the - stone to obtain a definite and regular shape are

form of block. called dressing.

Blasting To obtain stone at a - Dressing of stone is done immediately after

large scale. quarrying and before seasoning to achieve less

Blasting- weight for transportation.

Boring→Cleaning→Charging→Tamping→Firing ❑ TYPES OF STONES FINISHING-

Quantity of explosive (N)- (i) Boasted finishing-

PGCIL DT 2023, UPPCL JE 2022

JSSC JE 2022, PGCIL DT 2018, UPRVUNL JE 2016

2

N = [L.L.R.(in m)] × 1.5 (in gm) It is the making non-continuous parallel marks on

[L.L.R.(in m)]2 [L.L.R.(in cm )]2 the surface of stone.

N= kg N = kg It is done by a tools called boaster.

0.008 61

Where, L.L.R.=Length of line of least resistance (ii) Furrowed finishing-

It has beautiful appearance in which sides are sunk

❖ Explosive material used in blasting-

APSC JE 2018, SSC JE 2017, HPPSC AE 2016

up to 20 mm width and the middle portion is

projected by 15 mm.

Name of Chemical composition

Explosive (iii) Polished finish-

Blasting Gelatin Nitroglycerin (93%) + Gun- It is provided for marbles, granite which are mostly

Cotton (7%) used for floor tiles.

Use- In deep well, under- (iv) Reticulated finish-

ground work, in wet MPPGCL JE 2023

Condition A margin of 20 mm wide is marked on the sides of

Gun-Cotton Cotton with the solution of surface and irregular sinking type finish is made in

(most powerful) (HNO3 + H2SO4) the middle area.

Use- Where demolitions are (v) Tooled finish-

required. It is a classic finish which consists parallel

Dynamite Nitroglycerine (75%) + Fine continuous marks.

sand (25%)

(vi) Scrabbling finish-

Use- Both under water and

surface blasting The resultant rough surface finish achieved after

removing irregular projections on the stone surface

Blasting power Potassium nitrate (75%) +

by the scrabbling hammer.

/Gun powder Charcoal Powder (15%) +

Sulphur (10%) (vii) Vermiculated finish-

Use- In quarrying large block Sinking in this type of finish is more curved and like

Rock-a-Rock Potassium chlorate, 79% + worm eaten appearance.

Nitrobenzol, 21% Seasoning of stone-

Use-Best for under water and UPMRC JE 2020

damp situation blasting. The process under which quarry sap are remove

Cordite It is gelatinized combination from the stone are called seasoning.

of Nitroglycerine and

Nitrocellulose Time required for perfect seasoning of stone is-

Use- Under water 6 to 12 month.

Lithofracteur Nitroglycerine (33%) + ❖ Type of stone crusher and its equipment-

Nitrate of baryta (16%) + Crusher type Equipment

Sulphur (26%) + Kieselguhr

(22%) charcoal (3%) Primary Jaw crusher, Impact and

Use- In tunnels Gyratory crusher and Hammer

Detonator- mill Crusher.

It is used to trigger an explosive device. Secondary Roll crusher, Cone crusher,

• Length = 25 mm Hammer mill

• Diameter = 6 mm Tertiary Ball mill, Roll mill & Rod-mill

Civil Engineering Smart Scan 35 YCT

Test of Stone- Durability Test-

Specific Gravity Test- Durability is the ability of a material to resist

changes in its properties.

Aim– To find out the unit weight of stone.

For determining durability of stone the

Specific gravity of stone are following two types- crystallization (weathering resistance) test is

(a) Apparent Specific Gravity (IS : 1124 - 1974) prescribed by Bureau of Indian Standards.

Weight of stone/volume of stone The durability (Soundness) test is performed to find

= out the capacity of stone to resist disintegration and

Unit weight of water at 40 C decomposition.

(b) True Specific Gravity (IS : 1122 - 1974) Acid test to check weather resistance.

Brard's test for frost resistance.

Weight of stone particle/volume of stone particle

= Crushing Strength Test [IS : 1121 (Part-I)]

Unit weight of water at 40 C PGCIL DT 2023

Aim- To find out crushing strength of stone.

True specific gravity > Apparent specific gravity

Apparatus-Compression Testing Machine (CTM).

In case of stone, apparent specific gravity is most Size of Specimen-

frequently used which value is 2.4 to 2.8. (i) Cube (50 mm side)

Specific gravity of various types of stone- (ii) Cylinder (dia.- 50 mm, height- 50 mm)

DDA JE 2023, MP Vyapam Sub. Engg. 2022

Rate of loading- 140 kg/cm2/min

RPSC ACF & FRO 2021, DSSSB JE 2019, SJVN JE 2018

SJVNL JE 2021

Name of Stone Specific Gravity For good building stone compressive strength

Sand Stone 2.65 - 2.95 ≮100N/mm2 or 1000 kg/cm2

Marble 2.7 - 2.85 PPSC JE 2022, NHPC JE 2022

RIICO Draughtsman 2021

Granite 2.65 - 2.79

❖ Compressive Strength of Various Types of Stone-

Basalt 2.6 - 3.0 TNPSC AE 2019

Slate 2.72 - 2.89 Stone Compressive Strength (in M.Pa)

Laterite 2.0 - 2.2 Trap 350 - 380

Lime Stone 2.0 - 2.75 Gneiss 200 - 370

Gneiss 2.5 - 2.7 Basalt 150 - 180

Quartz 2.65 Slate 75 - 200

Water Absorption Test (IS : 1124 - 1974) Dolerite 90 - 150

Aim - To find out pore (air voids) in stone mass. Syenite 90 - 150

Granite 75 - 120

W2 − W1

w= ×100 Sandstone 64

W1

Lime stone 54

W1 = Weight of oven dry stone Key Points

W2 = Weight of stone after immersing in ■ The textures of a rock, the arrangement of minerals

is in the form of parallel layers– Foliated

water for 24 hours. ■ The rock exhibits less crushing strength when

w % of various types of stone >/ 5% and for compared to other mentioned type of rocks–

hydraulic structure >/ 0.5% Laterite

UPPCL JE 2018, GPSC AE Class-2 2021 ■ The correct unit of measurement for an item of

Stone is rejected if w % is > 10%. work 'Quarrying of stone or boulders' is–

Cubic metre

❖ Water absorption of various types of stone (after

24 hours)-

Transverse Strength Test [IS : 1121 (Part-II)]-

NHPC JE 2022, TSPSC AEE 2018 Aim-To find out the transverse strength of stone.

Size of specimen - Beam ( 200 × 50 × 50 mm)

Types of Stone Water absorption

(% not greater Effective length of specimen - 150 mm

than 3WL

Transverse strength R = N/mm2

Sand stone, Shale, Lime 10 2bd 3

stone Where,

Trap 6 W = Central breaking load in N

Quartzite 3 L = Length of span in mm

Granite, Gneiss, Slate 1 b = Average width of test piece in mm

d = Average depth in mm

Civil Engineering Smart Scan 36 YCT

Tensile Strength Test [IS : 1121 (Part III)] Important Point-

ISRO 2019, GES 2017

• Cylinder [dia. = 50 mm, H = 100 mm] Hard Steel ball are used in Brinell hardness test.

• Diameter to height ratio = 1 : 2 Corundum is a Amery type of stone.

Ammonia dynamite are used for tunneling in soft rock.

Shingle is a water bound pebbles.

Chronological order of Hydraulic conductivity

Vesicular basalt > Fractured metamorphic rock >

Lime stone > Sand stone.

Black marble is obtained from Jaipur.

2W Hydrolysis is a type of chemical weathering under

Tensile Strength S = which granite is convert into clay.

πDL

❖ Stone used in various work-

Where,

UPPSC AE 2013

W = Applied load in N

Hard stone Used in Rubble masonry

D = Diameter of specimen in mm

L = Length of specimen in mm • Cross cut saw is

used for cutting

Shear strength test [IS : 1121 (Part-IV)]-

This test is performed by Johnson shear tool or Heavy weight stone Used in Dam, retaining

wall and harbor

Dutton punching shear device.

Light weight stone In Arch masonry

Glance overview of stone test and

The load which is acting on the surface of stone,

purpose- must be normal to the natural bed of stone.

JSSC JE 2022, SJVNL JE 2021, GPSC JE 2020

Type of Test Determine for Marble and slate have low electric conductivity.

Abrasion Test Hardness and wearing Compacted sand stone has good fire resistance.

(By Dory Testing resistance Natural bed of stone is radial in arch and

Machine) perpendicular in wall masonry.

Attrition Test Hardness, Toughness and

(By Deval Testing rate of wearing resistance

Machine)

Crushing Strength Test Compressive strength

(By C.T.M)

(IS : 1121-1974)

Soluble minerals/ Muddy

matter.

Smith's Test

It is only qualitative

test.

Crystallization Test Durability

(IS : 1126-1974) JSSC JE 2022

Hardness Test Hardness

(Mohs Scale)

Impact Test Toughness

(By Page Impact Machine)

Water Absorption Test % Voids Colour of sedimentary rock is usually determined by Iron.

(IS 1124-1974) (≯5% for good stone) Biotite (rock forming mineral) are also known as

black mica.

❖ Bearing capacity of various types of stone-

Iron slag is used for manufacturing of garlic stone.

Stone Max. Bearing Baryta solution [Barium Hydroxide {Ba(OH)2}] is

Capacity (tone/m2) used on stone surface as preservative material.

Lime Stone 400 Calcium hydroxide is used to protect stones from

Schist and Shale 300 sulphate attack in Industries.

Clay Shale 100 Spalling hammer is used for rough dressing of stone.

Compacted sand stone 45 Broken bricks or stone chips are also called spall.

Granite 30 - 35 Composition of sand stone Quartz, Lime and Silica.

Loose gravel 25 Composition of granite Quartz, Feldspar, Mica.

Civil Engineering Smart Scan 37 YCT

02.

BRICKS

Function of Various Ingredients of Brick-

CHB JE 2023, ESE Pre. 2023, DDA JE 2023, MHADA JE 2022, UKPSC JE 2022, UKPSC AE 2022 (Paper-II), CGPSC AE 2022

Ingredients Properties Excess

Imparts strength and durability

Silica Prevents shrinkage, cracking and Brittle and weak on burning and

(main ingredient) warping disintegrate the corner of brick

(50-60%) Retain its uniform shape and make (Due to loss of cohesion)

sharp edge of brick

Increase shrinkage and warping of bricks

Introduce binding property and impart

Alumina during drying and burning.

plasticity

(20-30%) Cracks developed on surface and corner

deformed

Used as flux and reduces the

Lime shrinkage on drying (Reduce melting

(mixed in powder form) point) Brick over burnt and looses its shape

(10%) Causes silica in clay to melt on

burning and thus help to bind it

Used as flux

Iron Oxide

Provide red colour, strength and Provide dark blue or blackish colour

(< 7%)

hardness

Impart yellow colour & prevent

shrinkage,

Magnesia

In burning, it causes the clay to soften Decay of brick and give yellowish colour

(<1%)

at slower rate than does time and

reduces warping.

Note- ↓

Liquid limit of brick earth, 25 - 38%. 4. Drying

Plasticity index Ip, 7 - 13% i. Natural drying ii. Artificial drying

Harmful substance in brick earth- ↓

i. Lime stone or lumps 5. Burning

ii. Gravel, Kankar i. Pazawah or clamp ii. Intermittent kiln

iii. Alkalies iii. Semi continuous kiln iv. Continuous kiln

iv. Organic matter (Vegetables, roots) Unsoiling-

v. Sulphur The process of removing 20-30 cm thick the top

Note- layer of the earth which contain stone, kankar roots

As per the Bureau of Indian Standards, burnt clay and organic substance is termed as unsoiling.

bricks are classified in 11 classes based on their Digging-

minimum average compressive strength. The process of excavation of soil mass after

Vane diagram for manufacturing of unsoiling is called digging. The digging operation

brick- should be done before rain season.

DSSSB AE 2021 Weathering-

1. Site Selection SSC JE 2017

↓ Under this operation the excavated soil is left in

2. Preparation of brick earth exposed weather for some periods due to which it

↓ could achieved a good plasticity.

(i) Unsoiling → (ii) Digging→ (iii) Weathering→ Blending-

MH WRD JE 2022, SJVNL 2021, SSC JE 2020

(iv) Blending→ (v)Tempering→ Kneading or Pugging

The Process of mixing ingredient which is not

↓ present in sufficient quantity in brick earth and to

3. Moulding obtain uniform mixture is called blending.

The process of blending should be done at the time

i. Hand moulding, ii. Machine moulding of weathering.

Civil Engineering Smart Scan 38 YCT

Tempering- Size of various types of bricks-

Under this process required quantity of water is CHB JE 2023, UPRVUNL JE 2022, UPPCL JE 2022

added in soil mass and the whole mass is kneaded as MH WRD JE 2022, JSSC JE 2022, PPSC JE 2022

Pressed under the feet of men or cattle and obtain a DSSSB JE (Tier-I) 2022, UPPCL JE 2020, SSC JE 2020

KPSC JE 2016

homogeneous mass having uniform character.

Kneading or Pugging- Brick Nominal

Usual size

PGCIL DT 2023, ISRO 2018, SSC JE 2017 Classification size

Pugmill is used to preparation of brick earth it is "

called pugging or kneading.

Conventional/ " " 9"× 4 1 × 3"

2

For manufacturing good brick tempering is done in

Traditional/ 9"× 4 3 × 2 3

user size 8 4 or

pugmill. This operation is called pugging. (23×11.4×7.6)cm

The process of mixing water, clay and other Standard/ Modular/

ingredients to make bricks is called kneading. (19×9×9) cm (20×10×10)cm

Normal size

Weight of modular brick is ≃ 3kg.

Frog-

UPPCL JE 2016, UKPSC AE 2022, SSC JE 2022, DDA JE 2023

It is the depression on the top face of the brick made

by stock board.

Frog of brick is kept on the top while constructing a

wall so that mortar is filled properly in it.

Binding and shear strength of walls are increased

due to frog.

Object of frog is forming a key between two course

of brick wall.

Moulding- JKSSB JE 2022

The process of giving a required shape and size to

brick earth in the form of brick is called moulding. It

is two types-

(i) Hand moulding (ii) Machine moulding

Steel mould Wooden mould

Made of steel sheet It is generally made of Stock board- It is use for making frog on the

Shisham surface of brick.

Sharp surface and corner Compared to steel mould

are achieved is less

Per day brick moulding Its moulding capacity is

capacity is less more

Note-

Steel moulded bricks are good compared to wooden

moulded bricks.

Steel moulded brick are used in facing work.

Internal dimension of mould is 10% more than

completely burned brick. It is the approximately Strike-

same as nominal size of brick. It is use for removing excess soil from the surface of

mould. These are two type-

Key Points

(i) Wire strike, (ii) Wooden strike

■ The bricks which are extensively used for basic

refractories in furnaces are– Magnesite bricks

■ According to IS : 1077-1992, non–modular size of

the bricks is– 230×110×70 mm

■ Body bricks are well burnt bricks occupying

central portion of the kiln.

Civil Engineering Smart Scan 39 YCT

Pallet board– BPSC AE 2018 ❖ Strength of hand molded brick-

It is used to carry the moulded brick for drying. Strength Value (in kN/m2)

Crushing strength 60000

Shear strength 6000

Tensile strength 2000

MH WRD JE 2022

Burning of bricks

Steps used for burning of bricks-

Loading

↓

Pre-heating

Note- DFCCIL 2021 ↓

Frog 10 cm × 4 cm × 1 or 2 cm Burning

Stock Board 21 cm × 10 cm × 6 cm ↓

(To make frog)

Cooling

Pallet Board 30 cm × 12 cm × 1 cm

(To dry the brick) ↓

Unloading

Key Points

■ Second class bricks are recommended for–

Hidden masonry work

■ The general specification of first class building

mentioned below is associated to : "Shall be of

first class burnt brick work in lime or cement

mortar (1 : 6)"– Superstrucutres

■ The types of special mortars are used for setting

refractory bricks in the furnace linings where the

temperature is too high for ordinary mortars–

Fire–shielding mortars

Drying-

The main purpose of drying is to remove the

moisture to control the shrinkage and save fuel and

time during burning.

Green brick contain about 7 to 30% moisture

depending upon the method of manufacture.

Drying of brick is done by following two types

1. Natural drying-

Brick should be dried in shaded area, not in sun

light.

Number of brick course 7 to 8 ( in hollow)

Time required for dry = 3 to 7 day (depend on the

climate) Time required for burning of brick in the kiln is

2. Artificial drying- about 24 hours and only 12 days are required for

This method are use in rainy season or more brick cooling of brick.

are required in less interval. In this method kiln are Stage of burning zone- KPSC JE 2016

used for drying brick. Dehydration (400 - 6500C)

Strength of Sun dried brick, 15 - 25 (kg/cm2) ↓

average 21 kg/cm2 Oxidation (650 - 9000C)

Moisture content should be available in sun dry ↓

brick 3% - 4%. Vitrification (900 - 12000C)

Civil Engineering Smart Scan 40 YCT

(iv) Fourth class or jhama brick- GPSC AE 2021

• Due to over burned its shape and size are changed.

• Compressive strength = 300 – 350 kg/cm2

• Water absorption = 8 – 10%

Colour - Dark blue

Use : Soling coat of road and foundation.

Note-

According to IS code : bricks having compressive

strength < 35 kg/cm2 should not be used.

2. On the basis of grade (IS : 1071 - 1971)-

NBCC JE 2017, DFCCIL JE 2016

Grade of brick Min. Compressive strength

(kg/cm2)

Grade AA 140

Grade A 105

Grade B 70

Grade C 35

3. On the basis of compressive strength-

UP Awash Vikash Parishad 2022

Class Average Compressive Strength

Continuous kiln not less than (kg/cm2)

❑ CLASSIFICATION OF BRICK- 35 350

40 300

1. On the basis of physical and mechanical

25 250

Properties

20 200

(i) First Class Brick-

17.5 175

GPSC AE 2020-21 & 23 , MHADA JE 2022

PPSC JE 2022, GES 2019, DFCCIL 2018

15 150

• Minimum compressive strength 105 kg/cm2 12.5 125

10 100

• Water absorption after immersed in water for 24

7.5 75

hours 20% 5 50

• Weight – 2.75 – 3 kg 3.5 35

Colour- Uniform deep red or cherry red ❑ SPECIAL TYPES OF BRICKS-

Hardness- MPPGCL JE 2023, GPSC AE 2022

No impression should be left on the brick when a DSSSB JE 2019, NBCC JE 2018

scratch is made by a finger nail. 1. Refractory brick/Fire resistance brick-

It should be free from efflorescence. These brick are capable to resist very high

The surface should be smooth and rectangular with temperature up to 15000C without melting or

softening. RPSC ACF & FRD 2021

parallel, sharp and straight edges and square corner.

Lime quantity kept less so that brick burnt at high

A metallic sound should come when two bricks are

temperature of 1700 - 18000C.

struck against each other.

The minimum average compressive strength- 32.5

When a horizontal brick is kept on a vertical brick MPa.

and fall at a 1.5m height the horizontal brick should Water absorption- 4 - 10%

not be break. Colour- Whitish yellow or light brown.

(ii) Second Class Brick- Use- Furnace lining, hollow tiles etc.

MHADA JE 2022, DSSSB JE 2019, RPSC 2016 Refractory bricks are following three types-

2

• Minimum compressive strength 75 kg/cm UPPCL JE 2022, CGPSC AE 2021

• Water absorption 22% A. Acid refractory brick-

• Colour - Light red Ingredient: 95 - 97% silica + 1 - 2% lime

• The impression is left when scratched by finger nail. Use: Where acidic slag are formed.

• Dull sound formed if two bricks are strucked. B. Basic refractory brick-

These are use where basic slag are made. These are

(iii) Third class brick-

two types-

• It is also known as under burned brick.

2 a. Magnesia refractory brick-

• Minimum compressive strength 35 kg/cm RSMSSB JE 2022

• Water absorption < 25% Ingredient- 70% magnesium oxide (MgO) + 30%

• Colour - Yellowish silica and alumina

Civil Engineering Smart Scan 41 YCT

b. Dolomite refractory brick- ❑ TEST OF BRICK-

In these brick is carbonate of calcium and 1. Dimension Test (IS : 1077)-

magnesium [CaMg(CO3)2] are used as raw material RSMSSB JE 2016, UPSSSC JE 2015

Use : In shaft and rotary kilns, which are use for

production of lime and cement.

C. Neutral refractory brick-

Ingredient of these brick are bauxite, silica and iron

oxide. It is use where acidic or basic slag are made.

2. Hollow brick (IS : 3952)- SSC JE 2017

Maximum hollow 50% of total plan area.

It is use for making sound proof and heat resistance

wall.

3. Perforated Brick [IS : 2222]- ❖ For modular size brick-

For 20 brick Dimension Tolerance

(cm) (mm)

Length 380 ± 80

Width 180 ± 40

Total hollow area 30 - 40% of total plan area. Height-

Use- Covering wall sound proof and heat insulating (i) 9 cm 180 ± 40

wall construction. (ii) 4 cm 80 ± 20

Compressive strength </ 7N / mm 2 2. Warpage Test [IS : 3495 (Part-IV)]-

Water absorption >/ 15% Warpage of brick is measured with half of a flat steel

Efflorescence >/ 10% or glass surface and measuring ruler graduated in

Warpage >/ 3 % 0.5mm division or wedge of steel 60×15×15 mm.

4. Over-burnt brick-

In over burnt brick a soft molten mass is produced

and the brick loose their shape.

5. Under burnt brick-

NHPC JE 2022

When bricks are not burnt to cause complete

vitrification, the clay is not softened because of

insufficient heat and the pores are not closed. These

brick have higher degree of water absorption and 3. Efflorescence Test [IS : 3495 (Part III)]-

APSC JE 2020, DSSSB JE 2019, ESE 2016

less compressive strength.

Aim- To find the alkali matter of soluble salts

❖ Sample required for various brick test- present in brick.

I.S. Code No. of Efflorescence is characterized by the white patches

Bricks Test

Sample on the surface of the brick.

Compressive strength 3495-Part I 6 Depth of water in container = 25 mm

test

Percent area covered Efflorescence

Water absorption test 3495-Part II 5

by white Patches

Efflorescence test 3495-Part III –

0% Nil

Warpage test 3495-Part IV 10

Dimension test 1077 20 0% – 10% Slight

10% – 50% Moderate

Key Points >50% [But white patches

■ ...........are caused in bricks by entrapped air the does not change in powder Heavy/severe

void of clay– Lamination form]

■ ............ is comparatively finer and possesses better >50% [White patches Serious

adhesive and cohesive properties– Clay changes into powder form]

■ Refractory bricks are specially manufactured to– The efflorescence to be not more than moderate (10

withstand high temperature – 50%) for class 12.5 and not more than slight (<

■ The most important purpose of frog in a brick is 10%) for higher class.

to– Brick should be rejected if white powder available

Form keyed joint between bricks and mortar on the brick surface is > 50% of total area.

Civil Engineering Smart Scan 42 YCT

4. Compressive Strength Test [IS : 3495(Part-I)]- 6. Blister-

This test is performed by compression testing Broken blister are generally caused on the surface of

machine sewer pipes and drain tile due to air imprisoned

Rate of loading = 140 kg/cm2/minute during their molding.

Proportion of mortar to fill the frogs- 1:3 7. Lamination-

5. Water Absorption Test [IS : 3495(Part-II)]- It is the thin lamina produces on the brick faces.

Aim- To find out the existence of pores in brick. Cause-Entrapped air in clay voids.

W2 − W1 8. Bloating-

w= × 100

W1

Where,

w = Water absorption (in percent)

W1 = Weight of oven dry (105 ± 50 C) brick

W2 = Weight of brick after immersion it in water

for 24 hours.

If w < 7% Then brick is high resistance to damage

by freezing.

Field test of brick earth- This defect observed as spongy swollen mass over

1. Consistency test the surface of burnt brick. It is caused due to the

2. Moulding test

presence of excess carbonaceous matter and sulphur

3. Deformation and shrinkage test

in brick clay.

4. Strength test

9. Checks or Cracks-

5. Testing, nature of soil ground

This defect may be because of lumps of lime or

❑ DEFECT OF BRICKS excess of water.

1. Under burnt- 10. Black core-

Caused due to insufficient heat and are not able to If bituminous matter or carbon is present in brick

carry the desire load.

earth and they are not completely removed by

2. Over burnt-

oxidation, the brick result in black core. Prime cause

It occurs due to extremely high heat and not suitable

of brick black core is improper burning.

for construction work.

3. Lime bursting problem- 11. Spots-

A common defect of bricks/tiles which is caused by Due to presence of iron sulphide in brick earth, the

the hydration of quick lime particles. dark spots remains on the brick surface.

By mixing common salt in black cotton soils, lime Unsuitable for exposed masonry work.

bursting can be prevented, 0.5% Sodium chloride is 12. Brick spalling-

sufficient. It is the irregular portion of the brick away or fall off

Put all the bricks in water just after they removed from the surface.

from the kiln, this process is called docking. Cause-Heating of water inside brick.

4. Efflorescence- CIL MT 2020 IS : 3102 → Classification of burnt clay solid brick.

Presence of drying grey or white powder patches on Heavy duty burnt clay brick (IS : 2180)-

the brick surface is known as efflorescence. MP Vyapam 2022, ESE 2017

This defect is caused because of alkalis present in These are similar to burnt clay brick and of the same

bricks. size but with high compressive strength.

Burnt clay paving brick (IS : 3585)-

These are used in drive ways and for land scaping

parks and garden.

Compressive Strength </ 40 N / mm 2

Water absorption >/ 5%

Soling brick [IS : 5779]-

These are used for soling of roads.

5. Chuffs- Compressive strength </ 5 N / mm 2

DSSSB JE 2019, MPSE 2018, SSC JE 2017

The deformation of the shape of bricks caused by the Water absorption >/ 20%

rain water falling on hot brick is known as chuffs. Efflorescence >/ 10%

Civil Engineering Smart Scan 43 YCT

TILES It is used for manufacturing sanitary wares

The clay product which thickness is less than 40mm containers and crucibles, reactor chambers and

is known as tiles. electric insulators.

Burning of tiles is same as brick burning but some Glazing-