Tec FPR DRG A3a 205

Uploaded by

vijayTec FPR DRG A3a 205

Uploaded by

vijay1 2 3 4 5

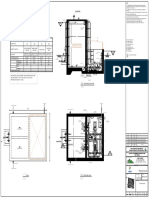

GENERAL KEY PLAN:

N

SCHEDULE OF FIRE PUMP EQUIPMENTS

PUMP SCHEDULE # DESCRIPTION SIZE/SPECS

LA

1. DIESEL ENGINE QIB

-

TANK

UNDERGROUND

MAIN BUILDING

DESIGNATION CAPACITY & HEAD PUMP TYPE SPEED APPROVAL UNDERGROUND

LOCATION

TANK

MAIN

BUILDING

NIC-A00-003-15

2. DIESEL FUEL TANK (0.68 M3 CAPACITY) -

VERTICAL TURBINE 3. DIESEL ENGINE / VERTICAL TURBINE FIRE PUMP 1500 GPM @ 125 PSI

MAIN FIRE PUMP SET 1500 GPM @ 125 PSI VERTICAL TURBINE 1750RPM UL & FM

1500 GPM @ 125 PSI

UNDERGROUND

TANK

4. ELECTRIC MOTOR / VERTICAL TURBINE FIRE PUMP

BUILDING

MAIN

(ELECTRIC DRIVEN)

VERTICAL TURBINE 5. JOCKEY / ELECTRIC VERTICAL TURBINE FIRE PUMP 20 GPM @ 135 PSI

STANDBY FIRE PUMP SET 1500 GPM @ 125 PSI VERTICAL TURBINE 1750RPM UL & FM

E (DIESEL DRIVEN) 6. OS & Y,GATE VALVE WITH TAMPER SWITCH DN200

7. CHECK VALVE DN200

JOCKEY PUMP SET

TANK

UNDERGROUND

-- --

BUILDING

MAIN

20 GPM @ 135 PSI VERTICAL CENTRIFUGAL

(ELECTRIC DRIVEN) 8. OS & Y,GATE VALVE WITH TAMPER SWITCH DN65

9. CHECK VALVE DN65

10. EXPANSION BELLOWS JOINT DN250

UNDERGROUND

TANK

MAIN

BUILDING

11. EXPANSION BELLOWS JOINT DN65

12. 2 X 12 VDC BATTERY & RACK -

13. FIBER GLASS INSULATION WITH ALUMINUM CLADDING -

14. DIESEL ENGINE EXHAUST PIPE SILENCER - NOTES:

15. DIESEL ENGINE EXHAUST PIPE DN 150

16. DIESEL FUEL SUPPLY LINE DN15 BLACK STEEL

17. DIESEL FUEL RETURN LINE DN15 BLACK STEEL

18. DIESEL ENGINE DRIVEN FIRE PUMP CONTROLLER -

19. ELECTRIC MOTOR DRIVEN FIRE PUMP CONTROLLER -

20. JOCKEY PUMP CONTROLLER -

21. SENSING LINE DN15 STAINLESS STEEL

D 22. SENSING LINE CHECK VALVE DN15

23. SENSING LINE GLOBE VALVE DN15

24. TEE PLUG (SENSING LINE) 6mm PLUG

25. ANGLE VALVE DN65 DN 65

26. EXHAUST FLAPPER -

REFERENCE NUMBER DESCRIPTION

G:\JED24-60478_33 to 13.8KV Secondary Substation\Work\00- FEED\Rev.02-Final\1-NIC-A00-003-015 [A3A]\8. Fire Protection System Drawings\03. PUMP ROOM\TEC-FPR-DRG-A3A-204.dwg

27. FIRE PUMP FLOW METERING DEVICE DN200

28. MAIN PRESSURE RELIEF VALVE, DN150 FLANGED

29. WASTE CONE DN150X250 FLANGED

0 500 MM 2500 MM 5000 MM

30. PRESSURE GAUGE -

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF NEOM. NO REPRODUCTION IN FULL, OR IN PART, SHALL BE OBTAINED FROM THIS DRAWING WITHOUT THE WRITTEN CONSENT FROM NEOM.

31. 2" AIR RELEASE VALVE - SCALE: 1:50 GRAPHIC SCALE

3 32. RAW WATER LINE TO DRAIN, DN25 - STAGE:

4

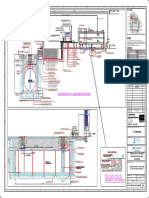

6 VJA-PS-ME Review: (21-05-2025):

As per NFPA 20 Section 7.2.2.1.2, the STAGE NO. - DESCRIPTION

REFER DWG No. TEC-FPR-DRG-A3A-200 submergence of the second impeller, measured NOTES:-

TANK FILLING LINE from the bottom of the pump bowl assembly, 2 ISSUED FOR APPROVAL APR.2025

1. FIRE PUMP AND CONTROLLER SHALL BE IN ACCORDANCE WITH THE

shall be at least 10 ft (3.2 m) below the pumping 1 ISSUED FOR REVIEW FEB.2025

water level when operating at 150 percent of the REQUIREMENT OF NFPA 20. 0 ISSUED FOR REVIEW JAN.2024

rated capacity 2. THE MINIMUM LENGTH BETWEEN CHECK VALVES SHALL BE AT LEAST REV DESCRIPTION APP DATE

C 1.5m. PURPOSE OF ISSUE:

3. THE STRAIGHT LENGTH SHALL BE REQUIRED 10 TIMES THE SUCTION

INFO/REVIEW

PIPE DIAMETER.

CLIENT: PROJECT MANAGEMENT CONSULTANT:

4. FIREWATER TANK SHALL BE SUPERVISED AT HIGH LEVEL, LOW LEVEL

VJA-PS-ME Review: (21-05-2025): AND LOW LOW LEVEL SHALL BE INTERFACE WITH FIRE ALARM SYSTEM.

The pump drawdown should be measured from 5. CABLE STAGING SHALL BE CONSIDER IN INSTALLATION PACKAGE

the minimum submergence level to the static ACCORDING TO HCIS SAF DIRECTIVES AND INTERNATIONAL STANDARD.

water level, and the aggregate capacity must be 6. THE 0.68 CUBIC METERS DIESEL TANK WILL BE ENOUGH FOR THE DIESEL

calculated accordingly. However, the total tank

PUMP TO BE WORKING FOR 12 HOURS ACCORDING TO NFPA20.

capacity is 592 cu.m, making it insufficient to

support two hours of operation. 7. A LOCAL VISIBLE AND AUDIBLE LOW LIQUID LEVEL SIGNAL SHALL BE

6400

PROVIDED IN THE TANK FILL MECHANISM.

UNDER GROUND WATER TANK-1 UNDER GROUND WATER TANK-2 8. EXTEND INTERNAL PIPING OF WATER INLET LINE NOZZLE AND TEST LINE

5549

DESIGN CONSULTANT NAME & LOGO (s): CONTRACTOR NAME & LOGO (s):

NOZZLE BELOW LEVEL OF THE FIRE WATER TANK.

9. THE OVERFLOW/DRAIN PIPE TO BE COORDINATED IN THE INSTALLATION

STAGE TO BE CONNECTED TO THE NEAREST DRAIN.

10. THE SHUTOFF (CHURN) PRESSURE OF THE FIREWATER PUMP (VERTICAL

VJA-PS-ME Review: (21-05-2025): TURBINE TYPE) SHALL NOT EXCEED 140% OF ITS RATED PRESSURE OR

TAJ AL JAZIRAH ENGINEERING CONSULTANCY

Please clarify how the tanks are to be partitioned 12.1 BAR (175 PSI) WHICHEVER IS IS SMALLER AS PER SAF-04

without interconnecting their water supplies, REQUIREMENT. tec-fire.com [email protected]

VJA-PS-ME Review: (21-05-2025) given that a single pump must deliver the 611 m³ 11. LOCAL CONTROL PANEL SHALL BE IN ACCORDANCE TO NFPA 20

As per NFPA 20 Section 14.2.6.3.6.1, water level

B detection is required for all vertical turbine pumps installed required for two hours of operation. DESIGN CONSULTANT / CONTRACTOR: NEOM'S REVIEW:

REQUIREMENTS.

in a well. This is necessary to monitor the water level at DRAWN: DRW M.A.

shutoff, as well as at 100 percent and 150 percent of rated

flow, to verify that the pump is operating within its design CHECKED: CHK M.M. CHECKED: CHK

parameters.

APPROVED: APR A.N. APPROVED: APR

SCALE: 1:50 SHEET SIZE: A1

DISCIPLINE NAME:

FIRE PROTECTION SYSTEM DRAWING

FIRE PUMP-SECTION A-A

PROJECT NAME:

MVSS 33/13.8kv SUBSTATIONS IN OXAGON

NIC-A00-003-015 [A3A]

OXAGON

NEOM

A

KINGDOM OF SAUDI ARABIA

MVSS 33/13.8kv SUBSTATIONS IN OXAGON REGION ASSET CODE CONTRACT CODE

NIC-A00-003-015 [A3A]

21/04/2025 5:12:15 م

03 371314 4800001271

FIRE PUMP-SECTION A-A GROUND FLOOR DRAWING NUMBER

1 FIRE PROTECTION SYSTEM DRAWING ORIGINATOR DISCIPLINE DOCUMENT TYPE SEQUENTIAL NUMBER REV NO.

FPR SCALE 1:50

TEC FPR DRG A3A-205 2

NEOM-NEN-PRC-010_TMP02_02.00

You might also like

- Fdas - Sprinkler - Fire Pump - Fire Pump Room For RFQ100% (1)Fdas - Sprinkler - Fire Pump - Fire Pump Room For RFQ49 pages

- Ficha Tecnica Motobomba Principal Patterson 6x5x14 SSC Ul-Fm 1000gpm@140psi - Puno0% (1)Ficha Tecnica Motobomba Principal Patterson 6x5x14 SSC Ul-Fm 1000gpm@140psi - Puno4 pages

- BCI - Curva y Drawing Patterson 4x3x11a ESNo ratings yetBCI - Curva y Drawing Patterson 4x3x11a ES3 pages

- Hydrant Post Connection: Pump House DiagramNo ratings yetHydrant Post Connection: Pump House Diagram1 page

- BOQ Fire Fighting (Hydrant) System R0 18-03-2020100% (2)BOQ Fire Fighting (Hydrant) System R0 18-03-20207 pages

- SECTION 15320 Fire Pumps and Accessories Part 1 General 1.01 Work IncludedNo ratings yetSECTION 15320 Fire Pumps and Accessories Part 1 General 1.01 Work Included9 pages

- Ficha Tecnica Motobomba SSC 2000gpm@180psi - MontanaNo ratings yetFicha Tecnica Motobomba SSC 2000gpm@180psi - Montana4 pages

- Fire Tank 200 KL Domestic Water Tank-1 175 KL Domestic Water Tank-2 175 KLNo ratings yetFire Tank 200 KL Domestic Water Tank-1 175 KL Domestic Water Tank-2 175 KL1 page

- Plot No.32, D-12 Markaz, Islamabad: Commercial & Apartment BuildingNo ratings yetPlot No.32, D-12 Markaz, Islamabad: Commercial & Apartment Building6 pages

- 4011-DRA-ABE-016-103-0010 - Rev03 - Process Drainage SystemNo ratings yet4011-DRA-ABE-016-103-0010 - Rev03 - Process Drainage System13 pages

- SCO-114 - UGT DETAILS R1 With Staircase UpdateNo ratings yetSCO-114 - UGT DETAILS R1 With Staircase Update1 page

- Dokumen - Tips - Marioff Hi Fog Gpu Systems For The Protection of Industrial Applications MarioffNo ratings yetDokumen - Tips - Marioff Hi Fog Gpu Systems For The Protection of Industrial Applications Marioff39 pages

- Design Basis of Fire Fighting Systems 1695377156No ratings yetDesign Basis of Fire Fighting Systems 169537715612 pages

- Specifications - Vertical Turbine Fire PumpsNo ratings yetSpecifications - Vertical Turbine Fire Pumps20 pages

- Single Wall Fuel Tank: FP 2.7 A-C Fire Pump SystemsNo ratings yetSingle Wall Fuel Tank: FP 2.7 A-C Fire Pump Systems1 page

- c3dci-Msft-ddc306-Ifc-Des-me-fps-gf-0100 - R0-Dammam MSFT Ddc306 Ancillary Buildings Ground Floor Fire Protection System LayoutNo ratings yetc3dci-Msft-ddc306-Ifc-Des-me-fps-gf-0100 - R0-Dammam MSFT Ddc306 Ancillary Buildings Ground Floor Fire Protection System Layout1 page

- 22036.2024-06-28.ServiceBlock - PlumbingSystems - MEP - 07No ratings yet22036.2024-06-28.ServiceBlock - PlumbingSystems - MEP - 071 page

- H&P ARG Rig 335 Equipment List From Final Wo100% (1)H&P ARG Rig 335 Equipment List From Final Wo12 pages

- F. P. General Notes: F. P. Legends & Symbols Fire and Jockey Pump ScheduleNo ratings yetF. P. General Notes: F. P. Legends & Symbols Fire and Jockey Pump Schedule1 page

- Day 2 - 3B - Submission Presentation - Session 5 - Fire & Life SafetyNo ratings yetDay 2 - 3B - Submission Presentation - Session 5 - Fire & Life Safety27 pages

- 03 006000 4200000074 CH2 FLS RPT 000005 NBNo ratings yet03 006000 4200000074 CH2 FLS RPT 000005 NB80 pages

- 14 191100 0000100120 Dah FLS DRG 101007 - CNo ratings yet14 191100 0000100120 Dah FLS DRG 101007 - C1 page

- 03 186005 4200000074 CH2 Arc DRG 011900 - PDF - ANo ratings yet03 186005 4200000074 CH2 Arc DRG 011900 - PDF - A1 page

- 13 213001 4200000086 Bei PLD SHD 000301 - 01No ratings yet13 213001 4200000086 Bei PLD SHD 000301 - 011 page

- Pm210011-Ais600-Uc1-00031 - 03 - LP Compressor Building Fire Protection System Hydraulic Calculation SupplyNo ratings yetPm210011-Ais600-Uc1-00031 - 03 - LP Compressor Building Fire Protection System Hydraulic Calculation Supply91 pages

- Problem Formulation and Methodology 3.1 Opening RemarksNo ratings yetProblem Formulation and Methodology 3.1 Opening Remarks7 pages

- Project On Measuring The Solubility of A Saturated SolutionNo ratings yetProject On Measuring The Solubility of A Saturated Solution9 pages

- Pressure Testing for Vessels in MalaysiaNo ratings yetPressure Testing for Vessels in Malaysia13 pages

- Solar Powered MBR Treating Wastewater For Reuse at A Hospital in Kampala - Pilot-Scale TrialsNo ratings yetSolar Powered MBR Treating Wastewater For Reuse at A Hospital in Kampala - Pilot-Scale Trials13 pages

- Lab 3 - Instructions - Wind Energy ModellingNo ratings yetLab 3 - Instructions - Wind Energy Modelling2 pages

- Design Parameters For Arbata Dam & Diversion SchemeNo ratings yetDesign Parameters For Arbata Dam & Diversion Scheme8 pages

- Geophysics Graduate CV: Suci Handayani QolbiNo ratings yetGeophysics Graduate CV: Suci Handayani Qolbi7 pages

- Electrical Engineer Resume - Saqib RasheedNo ratings yetElectrical Engineer Resume - Saqib Rasheed2 pages

- Petroleum (Exploration Development and Production) Act 2013No ratings yetPetroleum (Exploration Development and Production) Act 201375 pages

- EAMCET Sample Paper-7 (AP Eamcet 2014 - Medical Question Paper)No ratings yetEAMCET Sample Paper-7 (AP Eamcet 2014 - Medical Question Paper)30 pages

- G.E.R.M C+ Grid Earth Resistance MonitorNo ratings yetG.E.R.M C+ Grid Earth Resistance Monitor4 pages

- IET Power Electronics - 2019 - Bosso - Isolated Bidirectional DC To Three Phase AC Converter For Integration of RenewableNo ratings yetIET Power Electronics - 2019 - Bosso - Isolated Bidirectional DC To Three Phase AC Converter For Integration of Renewable11 pages