Industrial Silo Assembly Guide

Uploaded by

mostafanasr4Industrial Silo Assembly Guide

Uploaded by

mostafanasr4GENERAL NOTES :

- All dimensions are in millimeters.

5 4 3 11 - Unspecified Weld Thickness A=0.8*s.

- Max. permissible tolerances ovality %0.2 of the inside

diameter.

- The manufacturing company is obliged to check and

approve all dimensions before manufacturing and to report

missing or incorrect dimensions to ENTE project department.

- Longitudinal and circumferential seams shall not cross.

- Each longitudinal sheet plate welding shall be sequenced.

- All sheet weldings shall be seal weld. manufacturer shall

decide welding method and welding groove accordingly.

- Full penetrant is required.

- Magnetic test is required for weld joints.

n 3850

12664.8

13663.8

16 16 NUT DIN 934 - M27 CL 8

2 1 15

14

16

16

SPRING WASHER

WASHER

DIN 128 - A27

DIN 125 - A 28

St

St

13 16 HEXAGON BOLT DIN 933 - M27 x 90 CL 8.8

12 24 HEXAGON BOLT DIN 933 - M8 x 30 CL 8.8

11 1 RAILING 208-0104-0010-0

10 48 NUT DIN 934 - M8 CL 8

9 48 SPRING WASHER DIN 128 - A8 St

8 24 HEXAGON BOLT DIN 933 - M8 x 22 CL 8.8

7 48 WASHER DIN 125 - A 8,4 St

6 1 MINIMUM SWITCH

5 2 MAXIMUM SWITCH

4 1 PRESSURE RELIEF VALVE

3 1 FILTER

A 2 1 BIN ACTIVATORS

1:2 B

1 1 SILO WELDING 208-0104-0001-0

C MON.NR. ADET PARÇA ADI RESİM NO. STANDART NO. MALZEME

1:2 1:2 R5 FOR QUOTATION

R4 FOR INFORMATION

IT CAN NOT BE USED OR COPIED WITHOUT WRITTEN PERMISSSION.

R3 FOR APPROVAL

R2 FOR MANUFACTURING

R1 FOR CONSTRUCTION

REV.NO REVİZYON AÇIKLMA - Revision Explanation AS BUILT

BU TASARIMIN KULLANIM HAKKI ENTE A.Ş. AİTTİR.

THIS DRAWING IS SOLELY BELONG TO ENTE A.Ş.

MALZEME - Material BOYA KODU / Paint Code AĞIRLIK / Weight Page Size Sayfa / Sheet ADET - Quantity REVİZYON - Revision

İZİNSİZ KULLANILAMAZ VE KOPYALANAMAZ.

10639,056 kg A1 1/1 1

İSİM / Name TARİH / Date Genel Tolerans Barbaros Mah. Mor Sümbül Sok. No:5/310

general tolerance

ÇİZEN / Drawn by Halil İbrahim KORKMAZ 19.07.2023 Deluxia Palace Ataşehir- İSTANBUL-TÜRKİYE

DIN ISO'ya göre Phone: 00 90 (216) 290 07 47

KONTROL / Check. Haktan İbrahim YILMAZ

DIN ISO 2768-1 m, Fax : 00 90 (216) 290 43 83

ONAY / Appr. Süleyman DEĞER DIN ISO 2768-2 K

ÖLÇEK / Scale PROJE ADI ŞİRKET

1 : 40 Project Name MISIR GYPROC Company

12 7 9 10 7 8 10 9 13 16 15 14 MONTAJ ADI AKIŞ ŞEMASI No 300SL01

Assembly Name

100 m³ SILO FLOW SHEET Nr.

PARÇA ADI RESİM NO

Part Name Drawing Nr. 208-0104-0000-0

Form Revizyon No:1 / Tarih:15.02.2023

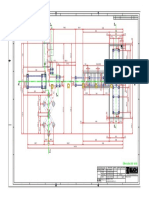

GENERAL NOTES :

- All dimensions are in millimeters.

- Unspecified Weld Thickness A=0.8*s.

10 9

3 A-A - Max. permissible tolerances ovality %0.2 of the inside

diameter.

A - The manufacturing company is obliged to check and

approve all dimensions before manufacturing and to report

missing or incorrect dimensions to ENTE project department.

- Longitudinal and circumferential seams shall not cross.

- Each longitudinal sheet plate welding shall be sequenced.

- All sheet weldings shall be seal weld. manufacturer shall

decide welding method and welding groove accordingly.

- Full penetrant is required.

- Magnetic test is required for weld joints.

6 5

EXISTING PART TO BE USED.

12974.8

12664.8

n 3850

°

62

1

56°

2064.8

1

100

n 1780 n 1780

A 7

8

11 4

45

44 64

64

45

44 60

41 40

40

41

60

45°

45°

11 1 Half Coupling Threaded - Class 3000 1/2 x 1/2 (BSP THREAD) 208-0104-4009-0 ASME B16.11

10 12 PLATE 208-0104-1031-0 St37.2

9 12 PLATE 208-0104-1030-0 St 37

8 1 PLATE 208-0104-1029-0 St 37

7 1 Coupling Threaded - Class 3000 1 x 1 (BSP THREAD) 208-0104-4006-0 ASME B16.11

45°

45°

6 1 SILO TOP CLOSING 208-0104-0005-0

5 4 LIFTING APPARATUS 208-0104-0003-0

4 4 CONNECTING FOOT 208-0104-0002-0

3 2 NPU 80 PROFILE 208-0104-3002-0 St 37

2 1 PLATE 208-0104-1005-0 St 37

1 2 NPU 120 PROFILE 208-0104-3001-0 St 37-2

MON.NR. ADET PARÇA ADI RESİM NO. STANDART NO. MALZEME

45°

45°

R5 FOR QUOTATION

R4 FOR INFORMATION

IT CAN NOT BE USED OR COPIED WITHOUT WRITTEN PERMISSSION.

R3 FOR APPROVAL

R2 FOR MANUFACTURING

45° R1 FOR CONSTRUCTION

45° REV.NO REVİZYON AÇIKLMA - Revision Explanation AS BUILT

BU TASARIMIN KULLANIM HAKKI ENTE A.Ş. AİTTİR.

THIS DRAWING IS SOLELY BELONG TO ENTE A.Ş.

MALZEME - Material BOYA KODU / Paint Code AĞIRLIK / Weight Page Size Sayfa / Sheet ADET - Quantity REVİZYON - Revision

İZİNSİZ KULLANILAMAZ VE KOPYALANAMAZ.

10505,764 kg A1 1/2 1

İSİM / Name TARİH / Date Genel Tolerans Barbaros Mah. Mor Sümbül Sok. No:5/310

general tolerance

ÇİZEN / Drawn by Halil İbrahim KORKMAZ 19.07.2023 Deluxia Palace Ataşehir- İSTANBUL-TÜRKİYE

DIN ISO'ya göre Phone: 00 90 (216) 290 07 47

KONTROL / Check. Haktan İbrahim YILMAZ

DIN ISO 2768-1 m, Fax : 00 90 (216) 290 43 83

ONAY / Appr. Süleyman DEĞER DIN ISO 2768-2 K

ÖLÇEK / Scale PROJE ADI ŞİRKET

1 : 40 Project Name MISIR GYPROC Company

MONTAJ ADI

100 m³ SILO

AKIŞ ŞEMASI No 300SL01

Assembly Name FLOW SHEET Nr.

PARÇA ADI RESİM NO

Part Name

SILO WELDING 208-0104-0001-0

Drawing Nr.

Form Revizyon No:1 / Tarih:15.02.2023

GENERAL NOTES :

- All dimensions are in millimeters.

- Unspecified Weld Thickness A=0.8*s.

- Max. permissible tolerances ovality %0.2 of the inside

A diameter.

- The manufacturing company is obliged to check and

approve all dimensions before manufacturing and to report

A-A missing or incorrect dimensions to ENTE project department.

- Longitudinal and circumferential seams shall not cross.

- Each longitudinal sheet plate welding shall be sequenced.

- All sheet weldings shall be seal weld. manufacturer shall

decide welding method and welding groove accordingly.

- Full penetrant is required.

330

- Magnetic test is required for weld joints.

10455

n 3850

EXISTING PART TO BE USED.

12664.8

1290

2209.8

2194.8

A

10.5° 29.5°

30°

20

°

°

30

30°

11 1 Half Coupling Threaded - Class 3000 1/2 x 1/2 (BSP THREAD) 208-0104-4009-0 ASME B16.11

10 12 PLATE 208-0104-1031-0 St37.2

30°

9 12 PLATE 208-0104-1030-0 St 37

4564

8 1 PLATE 208-0104-1029-0 St 37

10.5°

7 1 Coupling Threaded - Class 3000 1 x 1 (BSP THREAD) 208-0104-4006-0 ASME B16.11

30°

6 1 SILO TOP CLOSING 208-0104-0005-0

5 4 LIFTING APPARATUS 208-0104-0003-0

4 4 CONNECTING FOOT 208-0104-0002-0

3 2 NPU 80 PROFILE 208-0104-3002-0 St 37

2 1 PLATE 208-0104-1005-0 St 37

30°

1 2 NPU 120 PROFILE 208-0104-3001-0 St 37-2

MON.NR. ADET PARÇA ADI RESİM NO. STANDART NO. MALZEME

60

°

R5 FOR QUOTATION

30

R4 FOR INFORMATION

IT CAN NOT BE USED OR COPIED WITHOUT WRITTEN PERMISSSION.

R3 FOR APPROVAL

0

30

° 12 R2 FOR MANUFACTURING

30° R1 FOR CONSTRUCTION

30° REV.NO REVİZYON AÇIKLMA - Revision Explanation AS BUILT

BU TASARIMIN KULLANIM HAKKI ENTE A.Ş. AİTTİR.

THIS DRAWING IS SOLELY BELONG TO ENTE A.Ş.

MALZEME - Material BOYA KODU / Paint Code AĞIRLIK / Weight Page Size Sayfa / Sheet ADET - Quantity REVİZYON - Revision

İZİNSİZ KULLANILAMAZ VE KOPYALANAMAZ.

10505,764 kg A1 2/2 1

4564 İSİM / Name TARİH / Date Genel Tolerans Barbaros Mah. Mor Sümbül Sok. No:5/310

general tolerance

ÇİZEN / Drawn by Halil İbrahim KORKMAZ 19.07.2023 Deluxia Palace Ataşehir- İSTANBUL-TÜRKİYE

DIN ISO'ya göre Phone: 00 90 (216) 290 07 47

KONTROL / Check. Haktan İbrahim YILMAZ

DIN ISO 2768-1 m, Fax : 00 90 (216) 290 43 83

ONAY / Appr. Süleyman DEĞER DIN ISO 2768-2 K

ÖLÇEK / Scale PROJE ADI ŞİRKET

1 : 40 Project Name MISIR GYPROC Company

MONTAJ ADI

100 m³ SILO

AKIŞ ŞEMASI No 300SL01

Assembly Name FLOW SHEET Nr.

PARÇA ADI RESİM NO

Part Name

SILO WELDING 208-0104-0001-0

Drawing Nr.

Form Revizyon No:1 / Tarih:15.02.2023

GENERAL NOTES :

- All dimensions are in millimeters.

- Unspecified Weld Thickness A=0.8*s.

- Max. permissible tolerances ovality %0.2 of the inside

1 5 6 5 diameter.

- The manufacturing company is obliged to check and

approve all dimensions before manufacturing and to report

missing or incorrect dimensions to ENTE project department.

- Longitudinal and circumferential seams shall not cross.

- Each longitudinal sheet plate welding shall be sequenced.

- All sheet weldings shall be seal weld. manufacturer shall

decide welding method and welding groove accordingly.

- Full penetrant is required.

- Magnetic test is required for weld joints.

945

15

1290

15 15

205.8 265 265 205.8

30

203.3 260 260 203.3

270

270

45

8

30

4 2 3

1002.7 6 1 PLATE 208-0104-1013-0 St 37

5 2 PLATE 208-0104-1012-0 St 37

4 3 PLATE 208-0104-1011-0 St 37

3 1 PLATE 208-0104-1010-0 St 37

2 1 PLATE 208-0104-1009-0 St 37

12

1 1 PLATE 208-0104-1008-0 St 37

MON.NR. ADET PARÇA ADI RESİM NO. STANDART NO. MALZEME

R5 FOR QUOTATION

R1925 R4 FOR INFORMATION

IT CAN NOT BE USED OR COPIED WITHOUT WRITTEN PERMISSSION.

408.9

R3 FOR APPROVAL

330

R2 FOR MANUFACTURING

R1 FOR CONSTRUCTION

42

42

REV.NO REVİZYON AÇIKLMA - Revision Explanation AS BUILT

BU TASARIMIN KULLANIM HAKKI ENTE A.Ş. AİTTİR.

THIS DRAWING IS SOLELY BELONG TO ENTE A.Ş.

MALZEME - Material BOYA KODU / Paint Code AĞIRLIK / Weight Page Size Sayfa / Sheet ADET - Quantity REVİZYON - Revision

İZİNSİZ KULLANILAMAZ VE KOPYALANAMAZ.

342,054 kg A3 1/1 4

İSİM / Name TARİH / Date Genel Tolerans Barbaros Mah. Mor Sümbül Sok. No:5/310

general tolerance

ÇİZEN / Drawn by Halil İbrahim KORKMAZ 19.07.2023 Deluxia Palace Ataşehir- İSTANBUL-TÜRKİYE

190 190 KONTROL / Check. Haktan İbrahim YILMAZ

DIN ISO'ya göre Phone: 00 90 (216) 290 07 47

DIN ISO 2768-1 m, Fax : 00 90 (216) 290 43 83

ONAY / Appr. Süleyman DEĞER DIN ISO 2768-2 K

986.7 ÖLÇEK / Scale PROJE ADI ŞİRKET

1 : 10 Project Name MISIR GYPROC Company

MONTAJ ADI

100 m³ SILO

AKIŞ ŞEMASI No 300SL01

Assembly Name FLOW SHEET Nr.

PARÇA ADI RESİM NO

Part Name

CONNECTING FOOT 208-0104-0002-0

Drawing Nr.

Form Revizyon No:1 / Tarih:15.02.2023

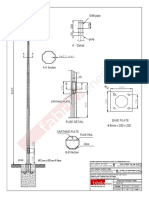

GENERAL NOTES :

- All dimensions are in millimeters.

- Unspecified Weld Thickness A=0.8*s.

- Max. permissible tolerances ovality %0.2 of the inside

diameter.

- The manufacturing company is obliged to check and

approve all dimensions before manufacturing and to report

missing or incorrect dimensions to ENTE project department.

- Longitudinal and circumferential seams shall not cross.

- Each longitudinal sheet plate welding shall be sequenced.

- All sheet weldings shall be seal weld. manufacturer shall

decide welding method and welding groove accordingly.

- Full penetrant is required.

- Magnetic test is required for weld joints.

n 60

250

2 1

77

2 1 PLATE 208-0104-1015-0 St 37

1 1 PLATE 208-0104-1014-0 St 37

MON.NR. ADET PARÇA ADI RESİM NO. STANDART NO. MALZEME

R5 FOR QUOTATION

169

15

R4 FOR INFORMATION

IT CAN NOT BE USED OR COPIED WITHOUT WRITTEN PERMISSSION. R3 FOR APPROVAL

R2 FOR MANUFACTURING

R1 FOR CONSTRUCTION

77

REV.NO REVİZYON AÇIKLMA - Revision Explanation AS BUILT

BU TASARIMIN KULLANIM HAKKI ENTE A.Ş. AİTTİR.

THIS DRAWING IS SOLELY BELONG TO ENTE A.Ş.

MALZEME - Material BOYA KODU / Paint Code AĞIRLIK / Weight Page Size Sayfa / Sheet ADET - Quantity REVİZYON - Revision

İZİNSİZ KULLANILAMAZ VE KOPYALANAMAZ.

7,817 kg A3 1/1 4

İSİM / Name TARİH / Date Genel Tolerans Barbaros Mah. Mor Sümbül Sok. No:5/310

general tolerance

ÇİZEN / Drawn by Halil İbrahim KORKMAZ 19.07.2023 Deluxia Palace Ataşehir- İSTANBUL-TÜRKİYE

DIN ISO'ya göre Phone: 00 90 (216) 290 07 47

KONTROL / Check. Haktan İbrahim YILMAZ

DIN ISO 2768-1 m, Fax : 00 90 (216) 290 43 83

ONAY / Appr. Süleyman DEĞER DIN ISO 2768-2 K

ÖLÇEK / Scale PROJE ADI ŞİRKET

1:2 Project Name MISIR GYPROC Company

MONTAJ ADI

100 m³ SILO

AKIŞ ŞEMASI No 300SL01

Assembly Name FLOW SHEET Nr.

PARÇA ADI RESİM NO

Part Name

LIFTING APPARATUS 208-0104-0003-0

Drawing Nr.

Form Revizyon No:1 / Tarih:15.02.2023

GENERAL NOTES :

- All dimensions are in millimeters.

- Unspecified Weld Thickness A=0.8*s.

- Max. permissible tolerances ovality %0.2 of the inside

diameter.

- The manufacturing company is obliged to check and

approve all dimensions before manufacturing and to report

missing or incorrect dimensions to ENTE project department.

- Longitudinal and circumferential seams shall not cross.

A-A - Each longitudinal sheet plate welding shall be sequenced.

5

- All sheet weldings shall be seal weld. manufacturer shall

decide welding method and welding groove accordingly.

- Full penetrant is required.

205

- Magnetic test is required for weld joints.

15°

7.5°

n

77 9

5 82

n

1 2

A A

2 1 PLATE 208-0104-1017-0 St 37

1 1 PLATE 208-0104-1016-0 St 37

MON.NR. ADET PARÇA ADI RESİM NO. STANDART NO. MALZEME

R5 FOR QUOTATION

R4 FOR INFORMATION

IT CAN NOT BE USED OR COPIED WITHOUT WRITTEN PERMISSSION. R3 FOR APPROVAL

R2 FOR MANUFACTURING

R1 FOR CONSTRUCTION

REV.NO REVİZYON AÇIKLMA - Revision Explanation AS BUILT

BU TASARIMIN KULLANIM HAKKI ENTE A.Ş. AİTTİR.

THIS DRAWING IS SOLELY BELONG TO ENTE A.Ş.

MALZEME - Material BOYA KODU / Paint Code AĞIRLIK / Weight Page Size Sayfa / Sheet ADET - Quantity REVİZYON - Revision

İZİNSİZ KULLANILAMAZ VE KOPYALANAMAZ.

21,715 kg A3 1/1 1

İSİM / Name TARİH / Date Genel Tolerans Barbaros Mah. Mor Sümbül Sok. No:5/310

general tolerance

ÇİZEN / Drawn by Halil İbrahim KORKMAZ 19.07.2023 Deluxia Palace Ataşehir- İSTANBUL-TÜRKİYE

DIN ISO'ya göre Phone: 00 90 (216) 290 07 47

KONTROL / Check. Haktan İbrahim YILMAZ

DIN ISO 2768-1 m, Fax : 00 90 (216) 290 43 83

ONAY / Appr. Süleyman DEĞER DIN ISO 2768-2 K

ÖLÇEK / Scale PROJE ADI ŞİRKET

1 : 10 Project Name MISIR GYPROC Company

MONTAJ ADI

100 m³ SILO

AKIŞ ŞEMASI No 300SL01

Assembly Name FLOW SHEET Nr.

PARÇA ADI RESİM NO

Part Name

SILO FILTER FLANGE 208-0104-0004-0

Drawing Nr.

Form Revizyon No:1 / Tarih:15.02.2023

GENERAL NOTES :

- All dimensions are in millimeters.

- Unspecified Weld Thickness A=0.8*s.

- Max. permissible tolerances ovality %0.2 of the inside

diameter.

- The manufacturing company is obliged to check and

approve all dimensions before manufacturing and to report

missing or incorrect dimensions to ENTE project department.

- Longitudinal and circumferential seams shall not cross.

- Each longitudinal sheet plate welding shall be sequenced.

- All sheet weldings shall be seal weld. manufacturer shall

decide welding method and welding groove accordingly.

- Full penetrant is required.

- Magnetic test is required for weld joints.

310

240

215

1000

1100

600

300

0

4

7.5°

2

45°

1000

650

535

735

935

1000

n 275

5 6 1 3

6 1 Coupling Threaded - Class 3000 1 x 1 (BSP THREAD) 208-0104-4006-0 ASME B16.11

5 1 Coupling Threaded - Class 3000 3/4 x 3/4 (BSP THREAD) 208-0104-4007-0 ASME B16.11

4 1 MANHOLE 208-0104-0007-0

3 1 MATERIAL INLET FLANGE 208-0104-0006-0

2 1 SILO FILTER FLANGE 208-0104-0004-0

1 1 PLATE 208-0104-1007-0 St 37

MON.NR. ADET PARÇA ADI RESİM NO. STANDART NO. MALZEME

R5 FOR QUOTATION

R4 FOR INFORMATION

IT CAN NOT BE USED OR COPIED WITHOUT WRITTEN PERMISSSION.

R3 FOR APPROVAL

R2 FOR MANUFACTURING

R1 FOR CONSTRUCTION

REV.NO REVİZYON AÇIKLMA - Revision Explanation AS BUILT

BU TASARIMIN KULLANIM HAKKI ENTE A.Ş. AİTTİR.

THIS DRAWING IS SOLELY BELONG TO ENTE A.Ş.

MALZEME - Material BOYA KODU / Paint Code AĞIRLIK / Weight Page Size Sayfa / Sheet ADET - Quantity REVİZYON - Revision

İZİNSİZ KULLANILAMAZ VE KOPYALANAMAZ.

530,297 kg A2 1/1 1

İSİM / Name TARİH / Date Genel Tolerans Barbaros Mah. Mor Sümbül Sok. No:5/310

general tolerance

ÇİZEN / Drawn by Halil İbrahim KORKMAZ 19.07.2023 Deluxia Palace Ataşehir- İSTANBUL-TÜRKİYE

DIN ISO'ya göre Phone: 00 90 (216) 290 07 47

KONTROL / Check. Haktan İbrahim YILMAZ

DIN ISO 2768-1 m, Fax : 00 90 (216) 290 43 83

ONAY / Appr. Süleyman DEĞER DIN ISO 2768-2 K

ÖLÇEK / Scale PROJE ADI ŞİRKET

1 : 20 Project Name MISIR GYPROC Company

MONTAJ ADI

100 m³ SILO

AKIŞ ŞEMASI No 300SL01

Assembly Name FLOW SHEET Nr.

PARÇA ADI RESİM NO

Part Name

SILO TOP CLOSING 208-0104-0005-0

Drawing Nr.

Form Revizyon No:1 / Tarih:15.02.2023

GENERAL NOTES :

45°

- All dimensions are in millimeters.

22.5° - Unspecified Weld Thickness A=0.8*s.

- Max. permissible tolerances ovality %0.2 of the inside

diameter.

- The manufacturing company is obliged to check and

approve all dimensions before manufacturing and to report

missing or incorrect dimensions to ENTE project department.

- Longitudinal and circumferential seams shall not cross.

- Each longitudinal sheet plate welding shall be sequenced.

- All sheet weldings shall be seal weld. manufacturer shall

decide welding method and welding groove accordingly.

- Full penetrant is required.

- Magnetic test is required for weld joints.

3

n 0.

24 16

0 n

85

n2

n 168.3

n 285

4

24

200

2 1 PN 16 DN 150 FLANS 208-0104-4008-0 DIN 1092-1 St 37

1 1 PIPE Ø114.3 x 4 208-0104-3003-0 DIN 2441 St37.2

MON.NR. ADET PARÇA ADI RESİM NO. STANDART NO. MALZEME

R5 FOR QUOTATION

R4 FOR INFORMATION

IT CAN NOT BE USED OR COPIED WITHOUT WRITTEN PERMISSSION. R3 FOR APPROVAL

R2 FOR MANUFACTURING

R1 FOR CONSTRUCTION

REV.NO REVİZYON AÇIKLMA - Revision Explanation AS BUILT

BU TASARIMIN KULLANIM HAKKI ENTE A.Ş. AİTTİR.

THIS DRAWING IS SOLELY BELONG TO ENTE A.Ş.

MALZEME - Material BOYA KODU / Paint Code AĞIRLIK / Weight Page Size Sayfa / Sheet ADET - Quantity REVİZYON - Revision

İZİNSİZ KULLANILAMAZ VE KOPYALANAMAZ.

10,386 kg A3 1/1 1

İSİM / Name TARİH / Date Genel Tolerans Barbaros Mah. Mor Sümbül Sok. No:5/310

general tolerance

ÇİZEN / Drawn by Halil İbrahim KORKMAZ 19.07.2023 Deluxia Palace Ataşehir- İSTANBUL-TÜRKİYE

DIN ISO'ya göre Phone: 00 90 (216) 290 07 47

KONTROL / Check. Haktan İbrahim YILMAZ

DIN ISO 2768-1 m, Fax : 00 90 (216) 290 43 83

ONAY / Appr. Süleyman DEĞER DIN ISO 2768-2 K

ÖLÇEK / Scale PROJE ADI ŞİRKET

1:2 Project Name MISIR GYPROC Company

1 2 MONTAJ ADI

100 m³ SILO

AKIŞ ŞEMASI No 300SL01

Assembly Name FLOW SHEET Nr.

PARÇA ADI RESİM NO

Part Name

MATERIAL INLET FLANGE 208-0104-0006-0

Drawing Nr.

Form Revizyon No:1 / Tarih:15.02.2023

GENERAL NOTES :

6 - All dimensions are in millimeters.

- Unspecified Weld Thickness A=0.8*s.

- Max. permissible tolerances ovality %0.2 of the inside

n 770 diameter.

- The manufacturing company is obliged to check and

approve all dimensions before manufacturing and to report

missing or incorrect dimensions to ENTE project department.

- Longitudinal and circumferential seams shall not cross.

- Each longitudinal sheet plate welding shall be sequenced.

- All sheet weldings shall be seal weld. manufacturer shall

decide welding method and welding groove accordingly.

- Full penetrant is required.

- Magnetic test is required for weld joints.

M12

7 5 1

140

220

n 710

4 2

3

41

7 1 MANHOLE BOTTOM HOLE 208-0104-0009-0

6 1 MANHOLE TOP COVER 208-0104-0008-0

5 2 STUD BOLTS 208-0104-4002-0 DIN 976-1 M12x140

4 4 SHAFT-1 208-0104-1018-0 St37

3 4 PIPE Ø26.9 x 3.2 208-0104-3004-0 DIN 2441 St37

2 8 SPLIT PIN 208-0104-4003-0 DIN 94 5x32

1 2 WING NUT 208-0104-4005-0 DIN 315 M12

MON.NR. ADET PARÇA ADI RESİM NO. STANDART NO. MALZEME

R5 FOR QUOTATION

R4

41

FOR INFORMATION

IT CAN NOT BE USED OR COPIED WITHOUT WRITTEN PERMISSSION. R3 FOR APPROVAL

R2 FOR MANUFACTURING

R1 FOR CONSTRUCTION

REV.NO REVİZYON AÇIKLMA - Revision Explanation AS BUILT

BU TASARIMIN KULLANIM HAKKI ENTE A.Ş. AİTTİR.

THIS DRAWING IS SOLELY BELONG TO ENTE A.Ş.

MALZEME - Material BOYA KODU / Paint Code AĞIRLIK / Weight Page Size Sayfa / Sheet ADET - Quantity REVİZYON - Revision

İZİNSİZ KULLANILAMAZ VE KOPYALANAMAZ.

69,140 kg A3 1/1 1

İSİM / Name TARİH / Date Genel Tolerans Barbaros Mah. Mor Sümbül Sok. No:5/310

general tolerance

ÇİZEN / Drawn by Halil İbrahim KORKMAZ 19.07.2023 Deluxia Palace Ataşehir- İSTANBUL-TÜRKİYE

DIN ISO'ya göre Phone: 00 90 (216) 290 07 47

KONTROL / Check. Haktan İbrahim YILMAZ

DIN ISO 2768-1 m, Fax : 00 90 (216) 290 43 83

ONAY / Appr. Süleyman DEĞER DIN ISO 2768-2 K

ÖLÇEK / Scale PROJE ADI ŞİRKET

1 : 10 Project Name MISIR GYPROC Company

MONTAJ ADI

100 m³ SILO

AKIŞ ŞEMASI No 300SL01

Assembly Name FLOW SHEET Nr.

PARÇA ADI RESİM NO

Part Name

MANHOLE 208-0104-0007-0

Drawing Nr.

Form Revizyon No:1 / Tarih:15.02.2023

GENERAL NOTES :

- All dimensions are in millimeters.

888 - Unspecified Weld Thickness A=0.8*s.

- Max. permissible tolerances ovality %0.2 of the inside

848

diameter.

8 - The manufacturing company is obliged to check and

A approve all dimensions before manufacturing and to report

5

missing or incorrect dimensions to ENTE project department.

133.8

- Longitudinal and circumferential seams shall not cross.

- Each longitudinal sheet plate welding shall be sequenced.

A n 20 - All sheet weldings shall be seal weld. manufacturer shall

decide welding method and welding groove accordingly.

- Full penetrant is required.

- Magnetic test is required for weld joints.

436.3

64

66

240

n 75

n6

2 160

4

4

70

160

n7

5 2 6 3 4 1

240

64

6 1 5mm EPDM GASKET 208-0104-4004-0 St 37

5 1 PLATE 208-0104-1023-0 St 37

4 4 PLATE 208-0104-1022-0 St 37

3 2 PLATE 208-0104-1021-0 St 37

2 1 PLATE 208-0104-1020-0 St 37

1 1 PLATE 208-0104-1019-0 St 37

MON.NR. ADET PARÇA ADI RESİM NO. STANDART NO. MALZEME

R5 FOR QUOTATION

R4 FOR INFORMATION

IT CAN NOT BE USED OR COPIED WITHOUT WRITTEN PERMISSSION. R3 FOR APPROVAL

R2 FOR MANUFACTURING

R1 FOR CONSTRUCTION

REV.NO REVİZYON AÇIKLMA - Revision Explanation AS BUILT

BU TASARIMIN KULLANIM HAKKI ENTE A.Ş. AİTTİR.

THIS DRAWING IS SOLELY BELONG TO ENTE A.Ş.

MALZEME - Material BOYA KODU / Paint Code AĞIRLIK / Weight Page Size Sayfa / Sheet ADET - Quantity REVİZYON - Revision

İZİNSİZ KULLANILAMAZ VE KOPYALANAMAZ.

37,242 kg A3 1/1 1

İSİM / Name TARİH / Date Genel Tolerans Barbaros Mah. Mor Sümbül Sok. No:5/310

general tolerance

ÇİZEN / Drawn by Halil İbrahim KORKMAZ 19.07.2023 Deluxia Palace Ataşehir- İSTANBUL-TÜRKİYE

DIN ISO'ya göre

A-A

5

Haktan İbrahim YILMAZ Phone: 00 90 (216) 290 07 47

KONTROL / Check.

DIN ISO 2768-1 m, Fax : 00 90 (216) 290 43 83

ONAY / Appr. Süleyman DEĞER DIN ISO 2768-2 K

20

n 666 ÖLÇEK / Scale PROJE ADI ŞİRKET

1 : 10 Project Name MISIR GYPROC Company

n 752 MONTAJ ADI

100 m³ SILO

AKIŞ ŞEMASI No

FLOW SHEET Nr.

300SL01

Assembly Name

PARÇA ADI RESİM NO

Part Name

MANHOLE TOP COVER 208-0104-0008-0

Drawing Nr.

Form Revizyon No:1 / Tarih:15.02.2023

GENERAL NOTES :

- All dimensions are in millimeters.

- Unspecified Weld Thickness A=0.8*s.

- Max. permissible tolerances ovality %0.2 of the inside

n 710 diameter.

- The manufacturing company is obliged to check and

5

approve all dimensions before manufacturing and to report

20

missing or incorrect dimensions to ENTE project department.

220

- Longitudinal and circumferential seams shall not cross.

- Each longitudinal sheet plate welding shall be sequenced.

- All sheet weldings shall be seal weld. manufacturer shall

40

decide welding method and welding groove accordingly.

- Full penetrant is required.

- Magnetic test is required for weld joints.

5 4

134

90

4

8

697 310

8

345

31 90

3 2 1

5 2 PLATE 208-0104-1028-0 St 37

4 1 PLATE 208-0104-1027-0 St 37

3 8 PLATE 208-0104-1026-0 St 37

2 2 PLATE 208-0104-1025-0 St 37

1 1 PLATE 208-0104-1024-0 St 37

MON.NR. ADET PARÇA ADI RESİM NO. STANDART NO. MALZEME

R5 FOR QUOTATION

R4 FOR INFORMATION

IT CAN NOT BE USED OR COPIED WITHOUT WRITTEN PERMISSSION. R3 FOR APPROVAL

R2 FOR MANUFACTURING

R1 FOR CONSTRUCTION

REV.NO REVİZYON AÇIKLMA - Revision Explanation AS BUILT

BU TASARIMIN KULLANIM HAKKI ENTE A.Ş. AİTTİR.

THIS DRAWING IS SOLELY BELONG TO ENTE A.Ş.

MALZEME - Material BOYA KODU / Paint Code AĞIRLIK / Weight Page Size Sayfa / Sheet ADET - Quantity REVİZYON - Revision

İZİNSİZ KULLANILAMAZ VE KOPYALANAMAZ.

29,619 kg A3 1/1 1

İSİM / Name TARİH / Date Genel Tolerans Barbaros Mah. Mor Sümbül Sok. No:5/310

general tolerance

ÇİZEN / Drawn by Halil İbrahim KORKMAZ 19.07.2023 Deluxia Palace Ataşehir- İSTANBUL-TÜRKİYE

DIN ISO'ya göre Phone: 00 90 (216) 290 07 47

KONTROL / Check. Haktan İbrahim YILMAZ

DIN ISO 2768-1 m, Fax : 00 90 (216) 290 43 83

ONAY / Appr. Süleyman DEĞER DIN ISO 2768-2 K

ÖLÇEK / Scale PROJE ADI ŞİRKET

1 : 10 Project Name MISIR GYPROC Company

MONTAJ ADI

100 m³ SILO

AKIŞ ŞEMASI No 300SL01

Assembly Name FLOW SHEET Nr.

PARÇA ADI RESİM NO

Part Name

MANHOLE BOTTOM HOLE 208-0104-0009-0

Drawing Nr.

Form Revizyon No:1 / Tarih:15.02.2023

GENERAL NOTES :

- All dimensions are in millimeters.

- Unspecified Weld Thickness A=0.8*s.

- Max. permissible tolerances ovality %0.2 of the inside

diameter.

- The manufacturing company is obliged to check and

approve all dimensions before manufacturing and to report

missing or incorrect dimensions to ENTE project department.

- Longitudinal and circumferential seams shall not cross.

- Each longitudinal sheet plate welding shall be sequenced.

- All sheet weldings shall be seal weld. manufacturer shall

decide welding method and welding groove accordingly.

- Full penetrant is required.

1170

- Magnetic test is required for weld joints.

620

60

75

120

5 8 10 8 4 6

20 ° 30°

°

40

30

°

944

n3

n

39

87

.7

30°

30°

2

30°

30°

10 2 PLATE 208-0104-1034-0 St 37

9 10 PIPE Ø33.7 x 2 208-0104-3008-0 DIN 2441 St 37

7 9 6 3 1 8 2 PIPE Ø33.7 x 2 208-0104-3007-0 DIN 2441 St 37

7 1 PIPE Ø33.7 x 2 208-0104-3010-0 DIN 2441 St 37

6 11 PIPE Ø33.7 x 2 208-0104-3009-0 DIN 2441 St 37

5 1 PIPE Ø33.7 x 2 208-0104-3006-0 DIN 2441 St 37

4 1 PIPE Ø33.7 x 2 208-0104-3005-0 DIN 2441 St 37

3 1 PLATE 208-0104-1033-0 St 37

2 1 PLATE 208-0104-1032-0 St 37

30

1 12 PLATE 208-0104-1031-0 St 37

30

°

MON.NR. ADET PARÇA ADI RESİM NO. STANDART NO. MALZEME

R5 FOR QUOTATION

R4 FOR INFORMATION

IT CAN NOT BE USED OR COPIED WITHOUT WRITTEN PERMISSSION.

R3 FOR APPROVAL

R2 FOR MANUFACTURING

30° R1 FOR CONSTRUCTION

30°

REV.NO REVİZYON AÇIKLMA - Revision Explanation AS BUILT

BU TASARIMIN KULLANIM HAKKI ENTE A.Ş. AİTTİR.

THIS DRAWING IS SOLELY BELONG TO ENTE A.Ş.

MALZEME - Material BOYA KODU / Paint Code AĞIRLIK / Weight Page Size Sayfa / Sheet ADET - Quantity REVİZYON - Revision

İZİNSİZ KULLANILAMAZ VE KOPYALANAMAZ.

118,881 kg A2 1/1 1

İSİM / Name TARİH / Date Genel Tolerans Barbaros Mah. Mor Sümbül Sok. No:5/310

general tolerance

ÇİZEN / Drawn by Halil İbrahim KORKMAZ 19.07.2023 Deluxia Palace Ataşehir- İSTANBUL-TÜRKİYE

DIN ISO'ya göre Phone: 00 90 (216) 290 07 47

KONTROL / Check. Haktan İbrahim YILMAZ

DIN ISO 2768-1 m, Fax : 00 90 (216) 290 43 83

ONAY / Appr. Süleyman DEĞER DIN ISO 2768-2 K

ÖLÇEK / Scale PROJE ADI ŞİRKET

1 : 20 Project Name MISIR GYPROC Company

MONTAJ ADI

100 m³ SILO

AKIŞ ŞEMASI No 300SL01

Assembly Name FLOW SHEET Nr.

PARÇA ADI RESİM NO

Part Name

RAILING 208-0104-0010-0

Drawing Nr.

Form Revizyon No:1 / Tarih:15.02.2023

You might also like

- Izgara Giriş Pusher Silindiri 4489.00.R00No ratings yetIzgara Giriş Pusher Silindiri 4489.00.R009 pages

- Izgara Giriş Pusher Silindiri 4489.00.R00No ratings yetIzgara Giriş Pusher Silindiri 4489.00.R001 page

- Izgara Giriş Pusher Silindiri 4489.00.R00No ratings yetIzgara Giriş Pusher Silindiri 4489.00.R001 page

- Dibba Bulk Handling Terminal FAT ReportNo ratings yetDibba Bulk Handling Terminal FAT Report23 pages

- TEP0000772243 - 1 - 40000056-10 - Straphyd Quality PlanNo ratings yetTEP0000772243 - 1 - 40000056-10 - Straphyd Quality Plan8 pages

- 888 E2-E3 (Carraro Şanzıman) - Servis Manuel - R16No ratings yet888 E2-E3 (Carraro Şanzıman) - Servis Manuel - R1613 pages

- Elkomix 135tw Al Saqabi Sons 2020 117 118 Temel Detay 5No ratings yetElkomix 135tw Al Saqabi Sons 2020 117 118 Temel Detay 51 page

- TEP0000729925 - 1 - 40000053-50 - 609,6x15,88 - ENAC - Quality PlanNo ratings yetTEP0000729925 - 1 - 40000053-50 - 609,6x15,88 - ENAC - Quality Plan8 pages

- Technical Specifications for Hydraulic ComponentsNo ratings yetTechnical Specifications for Hydraulic Components1 page

- Gupilya Split Pins Splint: DIN 94-ISO 1234 A2-A4No ratings yetGupilya Split Pins Splint: DIN 94-ISO 1234 A2-A4108 pages

- Galbiori 2 VP-25-077 - 2Vx24x2P - A1 - GENERAL ASSEMBLY Genel / GeneralNo ratings yetGalbiori 2 VP-25-077 - 2Vx24x2P - A1 - GENERAL ASSEMBLY Genel / General3 pages

- TEP0000767254 - 1 - 40000053-20 - 609,6x7,92 - ENAC - Quality PlanNo ratings yetTEP0000767254 - 1 - 40000053-20 - 609,6x7,92 - ENAC - Quality Plan8 pages

- Qualified Welder List For Sasa - 29.08.2024 3No ratings yetQualified Welder List For Sasa - 29.08.2024 32 pages

- NMP - Grade 3 Sample Mathematics Lesson Plan Booklet - 20201011 - v2100% (5)NMP - Grade 3 Sample Mathematics Lesson Plan Booklet - 20201011 - v2585 pages

- Class 10 Arithmetic Progressions: Answer The QuestionsNo ratings yetClass 10 Arithmetic Progressions: Answer The Questions14 pages

- FE Fluids Review - Notes and Problems113pdfNo ratings yetFE Fluids Review - Notes and Problems113pdf25 pages

- CS7-IR and Continuity Test Report For Electrical Cables 2022-08-21No ratings yetCS7-IR and Continuity Test Report For Electrical Cables 2022-08-211 page

- SOKALAN - High-Performance Additives For Thermal Desalination100% (1)SOKALAN - High-Performance Additives For Thermal Desalination7 pages

- Ballistic Galvanometer: Principles & DesignNo ratings yetBallistic Galvanometer: Principles & Design16 pages

- Getting The Whole Picture Wide-Azimuth Multicomponent SeismicNo ratings yetGetting The Whole Picture Wide-Azimuth Multicomponent Seismic7 pages

- How Are Habits Formed - Modelling Habit Formation in The Real World PDFNo ratings yetHow Are Habits Formed - Modelling Habit Formation in The Real World PDF13 pages

- 4CH0 1C Que 20190110-Edexcel-IGCSE-ChemistryNo ratings yet4CH0 1C Que 20190110-Edexcel-IGCSE-Chemistry28 pages