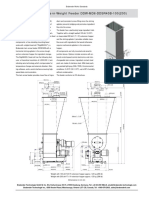

MECHATRON® “LS” Feeder

Volumetric and gravimetric MECHATRON® “LS” Feeders feature a range of

customer driven design attributes including all stainless steel construction,

AC drive packages, internal agitator, and helix configurations capable of

feed rates up to 21 cubic feet (595 Liters) per hour.

Additionally, MECHATRON® “LS” Feeders are the only feeders with

internal agitation that allow the feed hopper and helix to be removed,

cleaned, serviced or reconfigured without removing the internal

agitator from the extension.

MECHATRON® “LS” Feeders are especially well suited to applications

involving cohesive food, pharmaceutical, chemical, and plastic materials.

MATERIAL CONSTRUCTION: HOPPER EXTENSIONS:

Contact materials – • 1 cubic foot (30 liters) and 3 cubic feet (83 liters)

• 304 & 316 stainless steel (feed hopper, feed capacity with or without agitation.

screws, nozzles, and internal agitator). • Dust tight 360 degree band clamp mounting.

Non-contact materials –

• 304 stainless steel and epoxy coated or nickel MOTOR SPECIFICATIONS:

plated aluminum. • Industrial applications, helix drive – 1/2 HP (.37 kW) AC,

TEFC, inverter duty.

FEED RATES: • Industrial applications, agitation drive – 1/6 HP (.12 kW)

• Helix diameters from .25” (6 mm) to 1.38” AC, TEFC, inverter duty.

(35 mm) provide feed rates from .002 to 21 cubic • Industrial applications, agitation drive – 1/3 HP (.25 kW)

feet (.057 to 595 liters) per hour (theoretical). AC, TEFC, inverter duty.

• Optional twin screw helix diameters from .67” (17 mm) • 230/460 VAC, 3 PH, 60 Hz.

to 1.38” (35 mm) provide feed rates from .07 to 12 Note: Wash-down duty rated motors are used in feeders

cubic feet (2.1 to 343 liters) per hour (theoretical). intended for food and pharmaceutical applications.

FEED SCREWS:

MOUNTING CONFIGURATIONS:

• 304 or 316 stainless steel construction.

• Floor mount – 304 stainless steel tubular stand.

• Single and optional twin screw open flight or center-rod

configurations available. WEIGH MODULE SPECIFICATIONS: (optional)

• Full and half pitch configurations. • Dual Schenck stainless steel strain gauge

• Extensions from 12” (305 mm) to 48” (1,220 mm) load cells. No summing box required.

from the feeder face (actual maximums are helix • Weigh modules available in 132 lbs. (60 kg),

diameter dependent). 264 lbs. (120 kg), and 441 lbs. (200 kg).

CONI-STEEL™ FEED HOPPER: PERFORMANCE:

• Removable spun 70 degree (from horizontal) stainless • Volumetric accuracies of ± 2 to 5% of

steel conical feed hopper with or without internal agitator. feed rate setpoint typical at 2 sigma.

• .25 cubic feet (7.4 liters) material storage capacity. • Gravimetric accuracies of ± 1% of feed

rate setpoint typical at 2 sigma.

VOLUME Inlet Vent

NOTE: Laboratory testing to determine specific material

30 L 4.5” (115 mm) 4.5” (115 mm)

feeding accuracy is recommended and available from

83 L 6.63” (170 mm) 4.5” (115 mm) Schenck AccuRate.

BV-D5016GB

A feeder you can quickly reconfigure, clean,

or service from the non-process side.

1 2

All components are accessible from the rear of the feeder Swivel motor and drive assembly back and tighten hand

instead of the discharge side. Simply loosen the bolt and knob for complete access to all internal components for

the hand knob on the back of the coupling bell. easy cleaning, reconfiguration, and maintenance.

3 4

For easy removal of the helix, loosen the nuts of the three Release band clamp and lower the feed hopper to disengage

screws on the back of the coupling bell, allowing for fast the agitation system.

helix style, and diameter changes.

5 6

The feed hopper slides out for cleaning, replacement or Replace feed hopper, reposition motor and drive assembly,

maintenance. tighten hand knob and bolt, and you’re ready to run – all

in under two minutes.

gravimetric/

Hopper with

volumetric

mainframe

Extension

agitator

Vertical

control

motors

Gravimetric

.75” Nozzle

(19 mm)

1 cu. ft. (30 Liter)

0.16 HP Mechatronic 2@ 66 lbs.

Agitation Motor (30 kg)

2@132 lbs.

(60 kg)

Helix 2@220 lbs.

0.5 HP AC Remote (100 kg)

1.00” Nozzle

(25 mm)

Hanging

(optional)

3 cu. ft. (83 Liter)

0.33 HP

Agitation Motor

1.38” Nozzle

(35 mm)

Volumetric

EQUIPMENT CONFIGURATION WEIGHT HOPPER CAPACITY

inlet

Feeder + 1 cu. ft. (30 L) extension hopper

and cover assembly (dead load)..............................................100 lbs. (45 kg)..................1.30 cu. ft. (37 L)

24.6”

[625 mm] Stand + feeder + 1 cu. ft. (30 L) extension hopper

15.5” and cover assembly (total) . ..................................................163 lbs. (74 kg)..................1.30 cu. ft. (37 L)

[392 mm]

Vent

Feeder + 3 cu. ft. (83 L) extension hopper

and cover assembly (dead load)..............................................128 lbs. (58 kg)..................3.30 cu. ft. (90 L)

see note 3 Stand + feeder + 3 cu. ft. (83 L) extension hopper

B

and cover assembly (total) . ..................................................191 lbs. (86 kg)..................3.30 cu. ft. (90 L)

Notes:

7.1”

[180 mm]

1. Standard infeed to discharge (X) is 15” (385 mm).

Standard distance from front face of feeder (Y) is 7” (178 mm).

Extensions are available in one inch increments to the maximums stated below:

Helix Dia. Max. Infeed to Dis. (X) Max. FFOF (Y) Discharge Height (Z)

A .75” (19 mm) 19.7” (500 mm) 12” (305 mm) 6.42” (163 mm)

15.1” 1” (25 mm) 43.7” (1,100 mm) 36” (915 mm) 6.30” (160 mm)

[384 mm] 1.38” (35 mm) 55.7” (1,500 mm) 48” (1,220 mm) 6.10” (155 mm)

2. System scale capacity:

Total (2 Load Cells)

14.9” 132 lbs. (60 kg)

[379 mm]

264 lbs. (120 kg)

24.6”

[625 mm] 441 lbs. (200 kg)

3. Cover may be rotated up to 360° to meet application requirements.

Standard inlet and vents:

For 1 cu. ft. (30 L) hoppers = 4.50” DIN 100 inlet and 4.50” DIN 100 vent

14.1” For 3 cu. ft. (83 L) hoppers = 6.63” DIN 150 inlet and 4.50” DIN 100 vent

[358 mm]

Feeder 4. Electrical service requirements:

lifting 230V, 3 PH, 10.2 amps full load current, 60 Hz

holes

- or -

460V, 3 PH, 6.2 amps full load current, 60 Hz

X 15.8” 15.0 amp service is recommended for each motor.

[401 mm]

theoretical EXTENSION HOPPER DIMENSIONS

discharge Capacity Dim “A” Dim “B”

1.0 cu. ft. (30 L) 26.4” (671 mm) 19.2” (488 mm)

Z

3.0 cu. ft. (83 L) 35.9” (912 mm) 25.1” (638 mm)

feed hopper

Y removal

16.3”

** Overall height of feeder is increased by .5” (12.7 mm) to 1.25” (31.8 mm)

service area

[414 mm] when using optional leveling feet.

Schenck AccuRate

746 E. Milwaukee Street

Whitewater, WI 53190

800-558-0184 or Fax: 262-473-4384

E-mail: [email protected]

Web site: www.accuratefeeders.com BV-D5016GB ©2011 Schenck AccuRate