**Apron Feeders in Mining: A Comprehensive Overview**

**Introduction to Apron Feeders**

● What is an Apron Feeder?

○ An apron feeder, also known as a pan feeder, is a mechanical

type of feeder used in material handling operations.

○ Its primary purpose is to transfer material to other equipment or

extract material (such as ore or rock) from storage stockpiles,

bins, or hoppers at a controlled rate of speed.

○ Apron feeders find applications in primary, secondary, and

tertiary (reclaiming) operations within mineral processing

circuits.

**Advantages of Apron Feeders**

1.Precise Feed Control

○ Aprons prevent material from choking downstream equipment by

providing better feed control.

○ Ensures smooth material flow and prevents bottlenecks.

2.Shock Absorption

○ The shallow bed design allows apron feeders to absorb the

impact of loading material directly, minimizing wear.

○ Ideal for handling heavy and abrasive materials.

3.Versatility

○ Apron feeders can handle various dry or wet materials of

different sizes uniformly.

○ Flexibility in applications: primary, secondary, and reclaiming

operations.

**Tractor Chain Style Apron Feeders**

● Components of Tractor Chain Style Apron Feeders:

○ Undercarriage chain, rollers, and tail wheels (like those used in

bulldozers and excavators).

○ Polyurethane seals prevent abrasive materials from entering

internal pin and bushing, reducing wear.

○ Heat-treated chain links for increased service life.

○ Quieter operation due to reduced noise pollution.

● Benefits:

○ Increased reliability and uptime.

○ Fewer spare parts and less maintenance.

○ Better feed control, leading to minimal bottlenecks.

Applications of Apron Feeders

○ Primary Crushing and Material Handling: Apron feeders are

commonly used in mining operations to transport raw materials

from the primary crusher to downstream processing equipment.

They ensure a steady and controlled feed rate, optimizing the

efficiency of the crushing process.

○ Loading Hoppers and Stockpile Reclaim: Apron feeders are

utilized to load material into hoppers or reclaim material from

stockpiles. They are particularly useful in applications where

large volumes of material need to be handled and stored

efficiently.

○ Blending and Homogenization: Apron feeders can be used in

blending and homogenization processes, where different

materials are mixed together to achieve a consistent and

uniform composition. The controlled material flow of apron

feeders ensures precise blending and homogenization.

○ Other Material Handling Applications: Apron feeders are also

employed in industries such as cement, fertilizer, power

generation, and chemical. They are used for various material

handling tasks, including feeding raw materials to kilns,

transporting coal to boilers, and handling bulk materials in

processing plants.

○

**Installing Apron Feeders on an Incline**

Installing Apron Feeders on an Incline

Contrary to popular belief, apron feeders can be installed on an incline.

Here are the added benefits:

Improved Flow: Inclined installation allows better material flow.

Space Optimization: It saves horizontal space, especially in tight layouts.

Reduced Wear: Material slides more smoothly, reducing wear and tear.

Source(s)

1. apron feeder used in mining amalgamation|Mining Equipment – Northern Heavy

Industries Group Co., Ltd.

2. apron feeder used in mining amalgamation|Mining Equipment – Northern Heavy

Industries Group Co., Ltd.

3. apron feeder used in mining amalgamation|China Apron Feeder Mining Factory and

Suppliers, Manufacturers Direct ...

4. apron feeder used in mining amalgamation|Mining Weekly - Iron-ore miner gets new

apron feeder

5. apron feeder used in mining amalgamation|Apron Feeders, Apron Feeder Manufacture,

Apron Feeder Supplier —Henan ...

6. apron feeder used in mining amalgamation|The Solution On The Faults of Apron

Feeder

7. apron feeder used in mining amalgamation|Apron Feeder Machine for Coal in Crushing

Plants - China Feeder and ...

8. Feeding the facts: Apron feeder basics - Metso

9. Apron Feeder High-strength, heavy-duty productive processing - FLSmidth

10. Apron Feeders - BEUMER Group

11. Apron Feeders - Mining Life

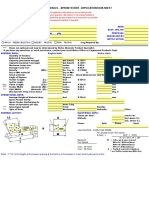

Components and Working Principle: The main components of

an apron feeder include the drive system, chains,

pans/flights, and support structure. The drive system

provides the necessary power to move the chains and pans.

The chains are responsible for moving the pans, which carry

the material. The material is loaded onto the pans, and as

the chains move, the material is transported to the desired

location.