Dwyer MSX

Uploaded by

OMAR ANTONIO ESTRADA ENRIQUEZDwyer MSX

Uploaded by

OMAR ANTONIO ESTRADA ENRIQUEZBulletin P-MSX-A

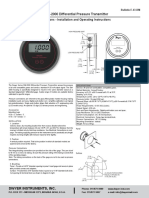

Series MSX Magnesense® Differential Pressure Transmitter

Specifications - Installation and Operating Instructions

1-1/16 [26.92]

3-9/64 33/64

[79.96] 1/2 NPSM 2-3/32 2-9/32

[13.08] [53.34] [57.79]

1-31/32

[49.89]

2-9/16

1-3/16 [30.02] 11/32 [8.56] [64.96]

Wall mount bracket [3] 3/16 [4.57] HOLES

EQUALLY SPACED ON A

4-7/64 [104.53] BC

3/8 [9.53]

7-31/64 [190.12]

Duct mount bracket

1-1/16 [26.92]

3-9/64 2-9/32

[79.96] 1/2 NPSM 33/64 [13.08] 2-3/32

[53.34] [57.79]

1-29/32

[48.36] 1-3/16

[30.02]

11/32 3-15/32

13/32 [8.56] [88.19]

1-43/64

[42.50] [10.29] 3-5/8

DIN mount bracket [92.08]

The Series MSX Magnesense® Differential Pressure Transmitter combines the SPECIFICATIONS

stability and versatility of the original Series MS2 Magnesense® II transmitter for use Service: Air and non-combustible, Loop Resistance: Current output:

in building control applications. The MSX simplifies the ordering process to deliver the compatible gases. 0-1250 Ω max; Voltage output: min. load

desired configuration, which reduces product setup time. Pressure ranges are available Wetted Materials: Consult factory. resistance 1 k Ω.

in Pa, mm w.c., and in w.c. All pressure ranges can be configured in unidirectional or Accuracy: ±1% FSO. Current Consumption: 21 mA max

bidirectional modes, providing a total of 32 ranges. The MSX transmitter can provide Stability: ±1% FSO/year. continuous.

a linear pressure output or a linear velocity output with the square root extraction from Temperature Limits: -4 to 158°F (-20 Electrical Connections: 4-wire

the transmitter. Additional parameters have been included to expand the square root to 70°C). removable European style terminal block

capability to calculate flow. Dual voltage and milliamp output signals can be used to Pressure Limits: Ranges 0 and 1: 3.6 for 16 to 26 AWG.

provide both control and equipment output signal verification. psi max operation, 6 psi burst; Ranges 2, Electrical Entry: 1/2˝ NPS thread.

3 and 4: 6 psi max operation, 6 psi burst. Display (optional): 4 digit LCD.

INSTALLATION Power Requirements: 10-36 VDC Process Connections: 1/8˝, 3/16˝, 1/4˝,

Surface Mounting: (2-wire), 17-36 VDC or isolated 21.6-33 5 mm, and 6 mm ID flexible tubing.

Mount the transmitter on a vertical surface. The pressure sensor measurement VAC (3-wire). Enclosure Rating: NEMA 4X (IP66); UL

is unaffected by orientation, but it is recommended the unit be mounted with the Output Signals: 4-20 mA (2-wire); 0-10 2043 (Plenum); UL94 V-0.

connections facing down to prevent moisture from entering either the pressure ports V or 0-5 V selectable (3-wire). Mounting Orientation: Pressure sensor

or the electrical cable entry. Attach the mounting flange to a flat surface using #8 x 1/2˝ Response Time: Instantaneous (default) measurement unaffected by orientation.

pan head sheet metal screws. Do not over tighten. or 3 s (selectable). Weight: 8.0 oz (230 g).

Zero and Span Adjustments: Digital Compliance: CE.

Duct Mounting (Universal Model Required): push-button.

Mount the transmitter away from fans, corners, heating and cooling coils and other

equipment that will affect the measurement of the pressure. OPTIONS

1. To mount the transmitter, drill a .562˝ (12.70 mm) diameter hole into the duct.

Range in w.c. Pa low Pa high mm w.c.

2. Screw duct probe into back of housing. Insert transmitter probe into the duct.

3. Mark location of mounting holes on duct using mounting flange as template. Drill Range 0 0.1 25 60 2.5

holes. 0.15 30 75 5

4. Attach mounting flange to duct with #8 x 1/2˝ pan head sheet metal screws. Do 0.25 40 100 10

not over tighten screws. 0.5* 50 125* 12*

5. Place the included cap on the exterior positive pressure port. Range 1 0.1 25 100 2.5

0.25 40 150 5

The Universal model can also be used as a standard wall mount transmitter. In this 0.5 50 160 10

mode, do not use the duct probe and plug the port on the backside of the transmitter 1* 60 250* 25*

with the included plug. Range 2 1 250 600 25

2 300 750 50

3 400 1000 100

5* 500 1250* 125*

Range 3 10 1000 3000 250

15 1500 4000 350

25 2000 5000 500

28* 2500 7000* 700*

Range 4 1 250 1000 25

5 300 2000 125

10 400 3000 250

15* 500 4000* 400*

*Indicated values are the positive full scale output values per range.

Note: Ranges indicated in the table are the high end of the set

range. All ranges have a low end pressure value of 0.

DWYER INSTRUMENTS, INC. Phone: 219-879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219-872-9057 e-mail: [email protected]

ELECTRICAL 3-Wire 0-10 V and 0-5 V Voltage Output

The MSX transmitter utilizes a 2-wire 4-20 mA Current Output, or a 3-wire 0-5 V

/ 0-10 V Voltage Output. It is also capable of Simultaneous Current and Voltage CAUTION DO NOT EXCEED SPECIFIED SUPPLY VOLTAGE RATINGS.

Output. The power and signals interconnect via a removable European-style four PERMANENT DAMAGE NOT COVERED BY WARRANTY WILL

conductor terminal block. RESULT.

NOTICE If equipped, the LCD must be removed before wiring. Pull the LCD The terminal block is removable and each of the terminals are labeled next to the

directly away from the product to remove. Reinstall the LCD after terminal block on the circuit board. Positive polarity is indicated by VOUT. AC/DC

wiring is completed. selection is made via the terminal block. If the polarity of the transmitter is inadvertently

reversed, the unit will not function properly, but no damage will be done to the

2-Wire 4-20 mA Current Output transmitter.

CAUTION DO NOT EXCEED SPECIFIED SUPPLY VOLTAGE RATINGS. Selection of using a DC or AC power supply is made via the terminal block.

PERMANENT DAMAGE NOT COVERED BY WARRANTY WILL See Figure 2 for DC Wiring.

RESULT. SIMULTANEOUS OUTPUTS ARE NOT DESIGNED FOR AC VOLTAGE See Figure 3 for AC Wiring.

OPERATION.

VOUT

The connections to the transmitter are made through terminals VDC and COM on

COM

VDC

VAC

the terminal block as shown in Figure 1. The terminal block is removable and each

of the terminals are labeled next to the terminal block on the circuit board. Polarity is

indicated by VDC and COM. See Figure 1. VOUT

COM

VDC

VAC

DC POWER VOLTAGE

+ SUPPLY - - RECEIVER +

17-36 VDC

Figure 2: DC wiring

DC POWER

SUPPLY - - CURRENT +

+ RECEIVER

10-36 VDC

VOUT

COM

VDC

VAC

Figure 1

The maximum receiver load resistance (RL) for a given power supply voltage (Vps) is

defined by the formula:

Vps - 10.0

RL =

20 mA DC

Shielded 2-wire cable is recommended for control loop wiring. Ground the shield at the

power supply end only.

AC POWER VOLTAGE

The receiver may be connected to either the negative or positive side of the loop, SUPPLY - +

RECEIVER

whichever is most convenient. Should polarity of the transmitter or receiver be 21.6-33 VAC

inadvertently reversed, the loop will not function properly but no damage will be done

to the transmitter.

Figure 3: AC wiring

The maximum length of connecting wire between the transmitter and the receiver is

a function of wire size and receiver resistance. That portion of the total current loop The minimum receiver load is 1 kΩ. The resistance due to the wire should be low

resistance represented by the resistance of the connecting wires themselves should compared to the receiver load resistance. While the voltage at the terminal block

not exceed 10% of the receiver resistance. For extremely long runs (over 1,000 feet), it remains unchanged with a 10 mA current flow, resistive losses in the wiring do cause

is desirable to select receivers with lower resistances in order to keep the size and cost errors in the voltage delivered to the receiver. For a 1% accurate gage, the resistance

of the connecting leads as low as possible. In installations where the connecting run of the wires should be less than 0.1% of the value of the receiver load resistance. This

is no more than 100 feet, you can use a connecting lead wire as small as No. 22 ga. will keep the error caused by the current flow below 0.1%.

The output across VOUT and COM will be either 0-5 V, 0-10 V depending on the DIP

switch setting. See DIP Switch Settings Section for more information.

Simultaneous Current and Voltage Output Power Supply

Refer to the following tables for the required supply rating.

CAUTION DO NOT EXCEED SPECIFIED SUPPLY VOLTAGE RATINGS.

PERMANENT DAMAGE NOT COVERED BY WARRANTY WILL Current Output

RESULT. SIMULTANEOUS OUTPUTS ARE NOT DESIGNED FOR AC VOLTAGE Supply Voltage 10-36 VDC

OPERATION. Loop Resistance 0-1250 Ω

Voltage Output

VOUT

COM

VDC

VAC

Supply Voltage 17-36 VDC

21.6 to 33 VAC isolated

Minimum Output Load Resistance 1000 Ω

DIP SWITCH SETTINGS

DIP switch settings are marked directly on the PCBA as shown in Figure 5. Switches

are factory-set, based on the order configuration. You can also use a small screwdriver

or pen to change the position of the switches.

+ CURRENT -

RECEIVER

NOTICE Figure 5 is a depiction of a 5 in w.c. pressure board. Other pressure

boards, while similar, will vary from the below.

WARNING There are no hazardous voltages if supplied power is within the

DC POWER VOLTAGE

+ SUPPLY - - + specified range. However, it is a good idea to shut control systems

RECEIVER down while changing DIP switches to prevent erratic control system behavior.

10-36 VDC

Figure 4: Simultaneous current and voltage output wiring

The terminal block is removable and each of the terminals is labeled underneath the

terminal block on the circuit board. Positive polarity is indicated by VOUT. The VDC

terminal and a DC power supply must be used for simultaneous current and voltage

output. The voltage output and the power supply must have separate wire leads that

are only joined at terminal 2 of the transmitter. Additional error may occur for the

voltage output if a single wire is used or if the wires are joined at the power supply or

receiver.

For the current output, the maximum allowable loop resistance (wiring + receiver

resistance) is dependent on the power supply. The maximum loop voltage drop must

not reduce the transmitter voltage below 17 V. The maximum loop resistance (RMAX)

for a given power supply voltage (VPS) can be calculated using the following equation:

(VPS – 17.0)

RMAX =

20 mA DC Figure 5: 5 in w.c. pressure board

The equation uses 17.0 instead of 10.0 as seen in the equation earlier with Figure

1. This represents the minimum voltage supply which is higher on the simultaneous

output configuration due to the requirements of the voltage outputs. Key To DIP Switch Settings

Switches are numbered 1 to 8 beginning on the left.

Shielded 4-wire cable is recommended for control loop wiring. Ground the shield

at the power supply end only. Should the polarity of the transmitter or receiver be DIP Switches 1 and 2 - Unit of Measure Selection

inadvertently reversed, the unit will not function properly, but no damage will be done DIP Switches 1 and 2 work as a pair to select the unit of measure.

to the transmitter.

PRESSURE UNIT SELECTION - DIP SWITCH 3 IS OFF (DOWN)

For voltage outputs, the minimum receiver load is 1 kΩ. The resistance due to the

wire should be low compared to the receiver load resistance. While the voltage at the DIP Switch 1 DIP Switch 2 Unit of Measure

terminal block remains unchanged with a 10 mA current flow, resistive losses in the ON ON Pa (low ranges)

wiring do cause errors in the voltage delivered to the receiver. For a 1% accurate gage, ON OFF Pa (high ranges)

the resistance of the wires should be less than 0.1% of the value of the receiver load OFF ON mm w.c.

resistance. This will keep the error caused by the current flow below 0.1%. OFF OFF in w.c.

The output across VOUT and COM will be either 0-5 V or 0-10 V depending on the DIP VELOCITY/FLOW UNIT SELECTION - DIP SWITCH 3 IS ON (UP)

switch setting. See DIP Switch Settings Section for more information. DIP Switch 1 DIP Switch 2 Unit of Measure

ON ON m3/hr (Flow)

ON OFF m/s (Velocity)

OFF ON CFM (Flow)

OFF OFF FPM (Velocity)

DIP Switch 3 - Pressure vs Velocity/Flow Mode of Operation DIP Switches 7 and 8 - Maximum Range Selection (Velocity/Flow)

DIP Switch 3 toggles between pressure output vs velocity or flow output. DIP switches 7 and 8 work as a pair to select the maximum range output of the

• When the switch is in the OFF or down position, the device is in Pressure Mode. transmitter. Use the tables below to navigate velocity and flow range selection.

• When the switch is in the ON or up position, the device is in Velocity/Flow Mode.

DIP Switch 4 - Voltage Output Range RANGE 0 PRESSURE RANGE SELECTIONS

Voltage output range can be either 0-10 V or 0-5 V depending on the position of DIP m3/hr m/s CFM FPM

Switch 4. DIP Switch 7 DIP Switch 8 (Flow) (Velocity) (Flow) (Velocity)

• When the switch is in the OFF or down position, the output will be 0-10 V. ON ON 1700 5 850 850

• When the switch is in the ON or up position, the output will be 0-5 V. OFF ON 2700 8 1250 1250

ON OFF 3700 11 2000 2000

DIP Switch 5 - Unidirectional vs Bidirectional Output OFF OFF 4800 14 2800 2800

DIP Switch 5 can be set to measure pressure in one direction (unidirectional) or in both

directions (bidirectional).

• When the switch is in the OFF or down direction, the transmitter will be set for uni- RANGE 1 PRESSURE RANGE SELECTIONS

directional and will be 0 based (i.e. 0 to 5 in w.c.). m3/hr m/s CFM FPM

• When the switch is in the ON or up position, the transmitter will be set for DIP Switch 7 DIP Switch 8 (Flow) (Velocity) (Flow) (Velocity)

bidirectional and will be ± the maximum of the selected range (i.e. ±5 in w.c.). ON ON 2500 7.5 1250 1250

OFF ON 3300 10 2000 2000

DIP Switch 6 - Response Time Selection ON OFF 5200 15 2800 2800

DIP Switch 6 toggles to select the desired response time. OFF OFF 6800 20 4000 4000

• When the switch is in the OFF or down direction, the transmitter response time will

be instantaneous.

• When the switch is in the ON or up direction, the response time will be 3 seconds. RANGE 2 PRESSURE RANGE SELECTIONS

m3/hr m/s CFM FPM

DIP Switches 7 and 8 - Maximum Range Selection (Pressure) DIP Switch 7 DIP Switch 8 (Flow) (Velocity) (Flow) (Velocity)

DIP switches 7 and 8 work as a pair to select the maximum range output of the

ON ON 6800 20 4000 4000

transmitter. Use the tables below to navigate pressure range selection. Alternatively, if

OFF ON 8600 25 5600 5600

using the device for velocity and flow, proceed to the next section.

ON OFF 11800 35 6900 6900

OFF OFF 15200 45 8950 8950

RANGE 0 PRESSURE RANGE SELECTIONS

DIP Switch 7 DIP Switch 8 Pa (set 1) Pa (set 2) mm w.c. in w.c. RANGE 3 PRESSURE RANGE SELECTIONS

ON ON 25 60 2.5 0.1 m3/hr m/s CFM FPM

OFF ON 30 75 5 0.15 DIP Switch 7 DIP Switch 8 (Flow) (Velocity) (Flow) (Velocity)

ON OFF 40 100 10 0.25

ON ON 18000 55 9000 9000

OFF OFF 50 125 12 0.5

OFF ON 23000 70 12000 12000

ON OFF 30000 90 15000 15000

RANGE 1 PRESSURE RANGE SELECTIONS OFF OFF 36000 107 20000 20000

DIP Switch 7 DIP Switch 8 Pa (set 1) Pa (set 2) mm w.c. in w.c.

ON ON 25 100 2.5 0.1

OFF ON 40 150 5 0.25 RANGE 4 PRESSURE RANGE SELECTIONS

ON OFF 50 160 10 0.5 m3/hr m/s CFM FPM

OFF OFF 60 250 25 1 DIP Switch 7 DIP Switch 8 (Flow) (Velocity) (Flow) (Velocity)

ON ON 7000 20 4000 4000

OFF ON 15000 45 9000 9000

RANGE 2 PRESSURE RANGE SELECTIONS ON OFF 21000 64 12000 12000

DIP Switch 7 DIP Switch 8 Pa (set 1) Pa (set 2) mm w.c. in w.c. OFF OFF 26000 78 15000 15000

ON ON 250 600 25 1

OFF ON 300 750 50 2

ON OFF 400 1000 100 3 CALIBRATION

OFF OFF 500 1250 125 5 There is a 3 second delay from the time the zero or span calibration buttons are

released until the time that the change in calibration takes place. This delay is used to

prevent stress related offsets on the lower ranges.

RANGE 3 PRESSURE RANGE SELECTIONS

DIP Switch 7 DIP Switch 8 Pa (set 1) Pa (set 2) mm w.c. in w.c. Zero Calibration

ON ON 1000 3000 250 10 The zero calibration can be set by applying zero pressure to both of the pressure ports

OFF ON 1500 4000 350 15 and pressing the zero button for 3 seconds. If the LCD display is present, the display

ON OFF 2000 5000 500 25 will read ZERO and then sequence back to the home display.

OFF OFF 2500 7000 700 28

Span Calibration

NOTICE For a positive span, apply pressure to the positive “+” port.

RANGE 4 PRESSURE RANGE SELECTIONS

DIP Switch 7 DIP Switch 8 Pa (set 1) Pa (set 2) mm w.c. in w.c.

The span calibration function allows the pressure value to be adjusted so that the

ON ON 250 1000 25 1

currently applied pressure is the maximum configured pressure. This will in turn set

OFF ON 300 2000 125 5

the maximum analog output at the set pressure. It is recommended that the ZERO

ON OFF 400 3000 250 10

function be applied before performing a span. Apply the maximum desired pressure

OFF OFF 500 4000 400 15

to the device, press and hold span for 3 seconds. If the LCD display is present, SPAN

is displayed. The span function will be processed 3 seconds after the span button is

released.

LCD DISPLAY MAINTENANCE/REPAIR

The LCD comes with a housing cover, which contains a window. The display plugs Upon final installation of the Series MSX, no routine maintenance is required. The

into the pins on top of the circuit board. The LCD is 180° rotatable so that it will read Series MSX is not field serviceable and should be returned if repair is needed. Field

properly if the device must be mounted with the connections facing up. repair should not be attempted and may void warranty.

The following error messages will appear if an LCD is present and the device is an This symbol indicates waste electrical products should not be disposed

error state.

of with household waste. Please recycle where facilities exist. Check with

your Local Authority or retailer for recycling advice.

LCD ERROR MESSAGES

Error Code Message WARRANTY/RETURN

OVER The applied pressure is 3% greater than the selected output high Refer to “Terms and Conditions of Sale” in our catalog and on our website. Contact

value causing an Over Range Error. customer service to receive a Return Materials Authorization (RMA) number before

UNDR The applied pressure is 1% less than the selected output low value shipping the product back for repair. Be sure to include a brief description of the

causing an Under Range Error. problem plus any additional application notes.

FAIL When the span button is pressed, the pressure value is out of the

range to allow a correct setting.

ER 1 The pressure applied to the sensor is beyond its ability to read.

ER 2 The pressure sensor is communicating but reporting an internal error.

ER 3 The pressure sensor is not communicating.

ER 4 The stored user settings are invalid.

ER 5 The stored factory settings are invalid.

ER 6 Non-volatile user memory has failed.

ER 7 Non-volatile factory memory has failed.

PROGRAM MENU

Home Menu

During normal operation, the display will be in the Home Menu and will display the

current measured pressure and the engineering units.

MSX MAIN UI AND PRESSURE FLOWCHART

MENU LEGEND

PRESS ZERO/VALUE BUTTON HOLD ZERO/VALUE BUTTON

POWER ON PRESS SPAN/DIGIT BUTTON HOLD SPAN/DIGIT BUTTON

(RESET) PRESS EITHER ZERO/VALUE HOLD BOTH ZERO/VALUE

OR SPAN/DIGIT BUTTON AND SPAN/DIGIT BUTTON

DISPLAY ALL

SEGMENTS

HOME

SCREEN

FIRMWARE VERSION

(MAY VARY)

HOME SCREEN

(MODE = PRESSURE) HOME

SCREEN

PIN MENU HOME

SCREEN

K-FACTOR MENU FLOW

MENU

VELOCITY

MENU

PRESSURE MENU

(OUTPUT LOW MENU)

PRESSURE MENU

(OUTPUT HIGH MENU)

PRESSURE MENU

(ALARM LOW)

PRESSURE MENU

(ALARM HIGH)

RESET MENU

S S

HOME

SCREEN POWER ON

(RESET)

MSX VELOCITY SETTINGS FLOWCHART

MENU LEGEND

PRESS ZERO/VALUE BUTTON HOLD ZERO/VALUE BUTTON

PRESS SPAN/DIGIT BUTTON HOLD SPAN/DIGIT BUTTON

PRESS EITHER ZERO/VALUE HOLD BOTH ZERO/VALUE

OR SPAN/DIGIT BUTTON AND SPAN/DIGIT BUTTON

VELOCITY

MENU

VELOCITY MENU

(OUTPUT LOW MENU)

VELOCITY MENU

(OUTPUT HIGH MENU)

RESET MENU

HOME POWER ON

SCREEN (RESET)

MSX FLOW SETTINGS FLOWCHART

FLOW

MENU

FLOW MENU

(AREA)

FLOW MENU

(OUTPUT LOW MENU)

FLOW MENU

(OUTPUT HIGH MENU)

RESET MENU

HOME POWER ON

SCREEN (RESET)

NOTES

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

©Copyright 2022 Dwyer Instruments, Inc. Printed in U.S.A. 5/22 FR# 444576-00 Rev. 3

DWYER INSTRUMENTS, INC. Phone: 219-879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219-872-9057 e-mail: [email protected]

You might also like

- Series DM-2000 Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsNo ratings yetSeries DM-2000 Differential Pressure Transmitter: Specifications - Installation and Operating Instructions2 pages

- Sensor de Caudal - Presión Estatica - MagnasenseNo ratings yetSensor de Caudal - Presión Estatica - Magnasense1 page

- Series 616KD-LR Low Range Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsNo ratings yetSeries 616KD-LR Low Range Differential Pressure Transmitter: Specifications - Installation and Operating Instructions2 pages

- Series DM-2000 Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsNo ratings yetSeries DM-2000 Differential Pressure Transmitter: Specifications - Installation and Operating Instructions2 pages

- P7650A/B/U: Differential Pressure SensorsNo ratings yetP7650A/B/U: Differential Pressure Sensors4 pages

- Industrial Pressure Transmitter: 0.13% FS Accuracy, External Adjustments, 4 To 20 Ma OutputNo ratings yetIndustrial Pressure Transmitter: 0.13% FS Accuracy, External Adjustments, 4 To 20 Ma Output3 pages

- Operating Instructions Electronic Pressure Sensor100% (1)Operating Instructions Electronic Pressure Sensor20 pages

- Wet/Wet Differential Pressure Switch: NEMA 4X Enclosure, Low Differential Set PointsNo ratings yetWet/Wet Differential Pressure Switch: NEMA 4X Enclosure, Low Differential Set Points1 page

- Series ISDP Intrinsically Safe Differential Pressure TransmitterNo ratings yetSeries ISDP Intrinsically Safe Differential Pressure Transmitter12 pages

- Industrial Pressure Transmitter/Transducer: SERIES 626 & 628No ratings yetIndustrial Pressure Transmitter/Transducer: SERIES 626 & 6282 pages

- Differential Pressure Transmitters 0-2.5 BarNo ratings yetDifferential Pressure Transmitters 0-2.5 Bar3 pages

- Transmisor Presion Diferencial dm-2007-lcdNo ratings yetTransmisor Presion Diferencial dm-2007-lcd2 pages

- P7640A, B Differential Pressure Sensors: ApplicationNo ratings yetP7640A, B Differential Pressure Sensors: Application4 pages

- Series 616W Differential Pressure Transmitter Specifications - Installation and Operating InstructionsNo ratings yetSeries 616W Differential Pressure Transmitter Specifications - Installation and Operating Instructions4 pages

- Magnehelic Differential Pressure Indicating TransmitterNo ratings yetMagnehelic Differential Pressure Indicating Transmitter1 page

- Duct Mount Pressure Transmitter InstallationNo ratings yetDuct Mount Pressure Transmitter Installation4 pages

- Transductor de Presin Diferencial Dwyer - XNo ratings yetTransductor de Presin Diferencial Dwyer - X2 pages

- Dwyer 626 13 GH P1 E4 S1 User Manual 0 300No ratings yetDwyer 626 13 GH P1 E4 S1 User Manual 0 3004 pages

- Magnesense Ii Differential Pressure Transmitter: Series Ms2No ratings yetMagnesense Ii Differential Pressure Transmitter: Series Ms22 pages

- Series 605 Magnehelic Differential Pressure Indicating Transmitter Specifications - Installation and Operating InstructionsNo ratings yetSeries 605 Magnehelic Differential Pressure Indicating Transmitter Specifications - Installation and Operating Instructions4 pages

- Project Delivery Scaffold Erecting Dismantling and Modification Inspection ChecklistNo ratings yetProject Delivery Scaffold Erecting Dismantling and Modification Inspection Checklist3 pages

- Specification V2.1: 1-Ch Differential Sensitivity Calibration Capacitive Touch SensorNo ratings yetSpecification V2.1: 1-Ch Differential Sensitivity Calibration Capacitive Touch Sensor13 pages

- ATNM Handrail 2277 DPR 04 04 2023 Report 07No ratings yetATNM Handrail 2277 DPR 04 04 2023 Report 071 page

- Charging Electric Vehicle Batteries Wired and Wireless Power Transfer Exploring EV Charging TechnologiesNo ratings yetCharging Electric Vehicle Batteries Wired and Wireless Power Transfer Exploring EV Charging Technologies16 pages

- Voltage Controlled Relay Ry 1-U: Terminals and Settings (Potentiometers)No ratings yetVoltage Controlled Relay Ry 1-U: Terminals and Settings (Potentiometers)1 page

- Experiment No. 2 Zener Diode ObjectivesNo ratings yetExperiment No. 2 Zener Diode Objectives18 pages

- Transistor Characteristics (Physics Practical)No ratings yetTransistor Characteristics (Physics Practical)2 pages