8Ao/" MILLING JIG F o RT E AR-15

DISCLAIMER: These instructions are intended for use by someone who has knowledge of machining and machine

tooling necessary to complete an 80% receiver. It is the end user's responsibility to determine if finishing an 80%

receiver is permitted by law in their state and/or municipality. These instructions are offered for educational purposes.

The author and jig manufacturer assumes no liability for misuse or damage; bodily, machinery, receiver or otherwise.

The purchase of this product and its instructions are acceptance of these terms.

Tools Needed:

Safety Glasses

DialCaliper

When dritting, use the peck drills method: to use the

t/2 End Mill peck dill method, use light pressure on the driil bit

3/g End Mill to driil smail amount. About.100 to .200 is

5/16 End Mi,

5/16 Lons End Miu - (receivers with intesrated

trigger guards ONLY)

:lfl"j[t"'1flj,.'*Ji? flll""xfjt[:H: l}fl**

process untilthe drill bit has fully drilled through the

5/g Drill receiver body'

3/g Drill

E/?2 l-lrill

The enclosed jig and instructions are intended for use with the 80% receivers and has been tested on

most popular forged and billet 80% receivers. This jig is specifically intended for use to finish 80%

re@ivers ONLY and is in no way designed to finish receivers any less than B0%

Please be safe in completing you project.

ALWAYS use eye protection and keep first aid supplies nearby if needed.

Take your time.

Measure twice and cut once.

Safety and patience will help you produce a quality product.

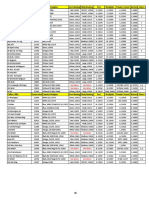

uide Pin

3/8 Drill in 2

places 5/8 Drill in 3 places

Drill 630 Drill 1.250 depth

de

5132 Drill 3/8 rill in 1 place

Guide Drill to 1 .250 depth

First Operation: Use the guide pins to align the Second Ooeration: Use the guide pins provided to

receiver take down with guide holes in jig plate. align the receiver take down pin holes with the

Place the first drill plate on top of the jig and secure guide holes in jig plate. Place the first drill plate on

with 114-20 bolts provided. Drill the trigger, hammer top of the jig and secure with 114-20 bolts provided.

pins, and the selector hole. Use the 5132'drill and The vise will secure the receiver in the jig. Be sure

guide holes in the jig to peck drill the trigger and not to over clamp the vise. Use the 5/8" drill in the

hammer pin holes. Peck drill the selector hole. Use first three large holes. Use caution when using the

the 3/8" drill and the guide hole in the jig to drill the large drill. Peck drill to a depth of 1.250. Use the

selector hole. 3/8" drill to drill the first small hole. peck drill to a

depth of 1.250. Use the 3/8" drill to drill the last two

small holes closest to the buffer tube hole. peck

drill to a depth of .630.

Follow contour in this area Follow contours in this area with 5/16 end mill to

with 3/8 end mill to.630 Follow contours in this area with 1.550 depth.

depth. 3/8 end mill to 1.250 depth.

Follow contour in this area with 112 end mill to

1.250 depth.

Third Ooeration: Use the guide pins provided to Fourth Operation: Use the guide pins provided to

align the receiver take down pin holes with the align the receiver take down pin holes with the

guide holes in the jig plate. Place the first driil plate guide holes in the jig plate. Ptace the first drill ptate

on top of the jig and secure with 1/4-20 bolts on top of the jig and secure with 114-20 bolts

provided. The vise will secure the receiver in the jig. provided. The vise will secure the receiver in

the jig.

Be sure not to over clamp the vise. The jig was Be sure not to clamp the vise. This operation is for

designed to use 5/8" drills in the main trigger group the slot the trigger fits through. Using a b116,, end

pocket to help minimize the amount of milling. Use mill, center the end mill in the trigger slot in the jig

the 1 12" end mill for the trigger/hammer portion of and slowly plunge the depth stated in the picture or

the pocket. Slowly plunge the end mill to half the until the end mill has drilled through the lower shelf

total depth of the pocket. Mill around the contour of of the receiver. Slowly follow the contours of the jig.

the jig mill plate. Repeat to full depth. Do the same

for the pocket portions that were drilled 3/8" drill

using the 3/8" end mill. Use the same process for

the rear take down lug pocket, but only going to a

finished denth nf A3O