Elements of Mechanical Engineering

Dr. Ranjeet Kumar Sahu

Assistant Professor

Department of Mechanical Engineering

National Institute of Technology Karnataka

Surathkal, Mangaluru, India

1

Heat engines

• Heat engine device which converts chemical energy of fuel into

heat energy & heat energy converted into mechanical work

• Heat engines are mainly classified into two types:

Internal combustion (EC) engines

External combustion (IC) engines

Contd….

IC engines

• Combustion of fuel takes place inside the cylinder

Examples Applications

Petrol engine Road vehicles

Diesel engine Locomotives

Gas turbine (Open) Aircraft

Rocket engine Space

Wankel engine Pump sets

Contd….

EC engines

• Combustion of fuel takes place outside the cylinder

Examples Applications

Steam engine Locomotives; Ships

Steam turbine Electric power generation

Hot air engine Submarines

Gas turbine (Closed) Aircraft

Contd….

Comparison of IC and EC engines

IC engines EC engines

Fuel combustion occurs inside cylinder Fuel combustion occurs outside cylinder

Compact in size and more efficient Larger in size and less efficient

Low initial cost More initial cost

Working fluid is mixture of air and fuel Working fluid is steam/gas

Less time required for starting More time required for starting

Costly fuels are required Cheaper fuels may be used

Contd….

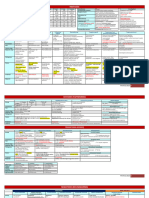

Classification of heat engines

Contd….

Classification of IC engines

• Type of fuel used Petrol; diesel; gasoline

• Type of ignition SI and CI

• Cycle of operation 2-stroke engine; 4-stroke engine

• Nature of thermodynamic cycle Otto cycle engine; Diesel

cycle engine; Dual cycle engine

• Speed of engine Low speed; medium speed; high speed

Contd….

• Method of cooling Air cooled; water cooled;

• Number of cylinders Single cylinder; multi-cylinder

• Cylinder arrangement In-line or straight engine

V-type engine

In-line or straight engine V-type engine

Components of IC engine

Cylinder head Piston pin Crankshaft Valves

Cylinder Connecting rod Crankcase Valve mechanisms

Piston Crank pin Main bearing Governor

Piston rings Crank Flywheel Fuel pump

Engine nomenclature

• Bore inside diameter of cylinder

• TDC top most position of piston

in cylinder away from crank

• BDC Lowest position of piston near

to crank

• Stroke Distance travelled by piston

from TDC to BDC or vice-versa

• Clearance volume Space between cylinder head and TDC of

piston

Contd….

• Swept volume/displacement volume volume displaced by piston

in moving between TDC and BDC

• Compression ratio (r) ratio of total cylinder volume to clearance

volume

• Piston speed average speed of the piston

• MEP MEP = Wnet / (V – Vc)

Engine operation

• 4-stroke cycle engine and 2-stroke cycle engine?

• SI engine and CI engine?

4-stroke cycle

SI engine

OR

4-stroke cycle

Petrol engine

Actual P-V diagram

Ideal P-V diagram

Ideal Valve Time Diagram Actual Valve Time Diagram

Contd….

4-stroke cycle

CI engine

OR

4-stroke cycle

Diesel engine

I.V. Inlet valve E.C. Engine cylinder

E.V. Exhaust valve C.R. Connecting rod

F.I. Fuel injector C Crank

Invented by Rudolf Diesel

(1892)

Higher compression ratio

Charge is air alone, no

carburetor.

No spark plug

Fuel is injected using fuel

pump and injector

Contd….

2-stroke cycle petrol engine 2-stroke cycle diesel engine

Contd….

Comparison of 4-stroke and 2-stroke engines

4-stroke engine 2-stroke engine

Cyclic operation is completed in four Cyclic operation is completed in two

strokes of the piston strokes of the piston

Power produced is less for same size Power produced is more for same size

Thermal efficiency is high Thermal efficiency is low

Valves used Ports used

Cooling and lubrication are less required Cooling and lubrication are more required

Costly for same power output Cheaper for same power output

Volumetric efficiency is more Volumetric efficiency is less

Contd….

Comparison of SI and CI engines

SI engine CI engine

Ignition system with spark plug is Ignition system with spark plug is not

required required

Petrol is used Diesel is used

Works on Otto cycle Works on Diesel cycle

Air fuel ratio – 10:1 to 20:1 Air fuel ratio – 18:1 to 100:1

Fuel supplied by carburetor Fuel supplied by fuel injection system

Compression ratio – 6 to 10 Compression ratio – 12 to 24

Thermal efficiency is low (order 25%) Thermal efficiency is low (order 40%)

Light in weight Heavy in weight

Contd….

Engine capacity

• Engine capacity swept volume or displacement volume

• Measured in cc or litres

• For multi-cylinder engines Engine capacity = Vs × no. of

cylinders

• More engine capacity More power and torque can be produced

at lower rpm consume more fuel

Firing order

Firing order refers to the sequence in which the charge in the various

cylinders of a multi cylinder engine is ignited and burnt.

Cylinders are ignited at the alternative ends of the crankshaft. This

enables the crankshaft to be stressed more or less uniformly along its

length.

When designing an engine, choosing an appropriate firing order is

critical

to minimizing vibration,

to improve engine balance and

achieving smooth running,

for long engine fatigue life and user comfort,

heavily influences crankshaft design.

Contd….

Fuel supply system in SI engine

• Fuel supply tank

• Fuel pump

• Fuel pipe lines

• Fuel filter

• Air filter

• Carburettor

Note: Carburetion

25

Contd….

Fuel supply system in CI engine

• Fuel supply tank

• Fuel feed pump

• Fuel filters

• FIP

• Fuel pipe lines

• Fuel Injector

• Air filter

26

Contd….

Functions of a fuel injection system

• Filter the fuel

• Measure the correct quantity of fuel to be injected

• Time the fuel injection

• Control the rate of fuel injection

• Atomise the fuel to fine particles

• Properly distribute the fuel into combustion chamber

27

Contd….

Lubrication system

• Crankshaft bearings

• Big end bearings

• Small end bearings

• Piston rings and cylinder walls

• Camshaft and camshaft bearings

28

Contd….

Cooling system

• Air cooling

• Water cooling

29