To Do - DS - LRFD - Supporting Beam - W8X18 - W8X18

Uploaded by

amitTo Do - DS - LRFD - Supporting Beam - W8X18 - W8X18

Uploaded by

amitall checks must be OK/ SAFE

3 3 6 3 3

kN ≡ N⋅ 10 kPa ≡ Pa⋅ 10 MPa ≡ Pa⋅ 10 kNm ≡ kN⋅ m ksi ≡ psi⋅ 10 kips ≡ lbf ⋅ 10 kipft ≡ kips⋅ ft

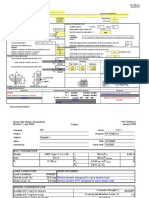

DESIGN OF SHEAR CONNECTION BY AISC 360-16- LRFD METHOD

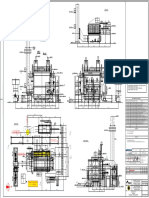

DS Connection (Beam to Beam by gusset plate+Splice plate)

Grade of Steel / Material Beam/Column

Gusset/Splice Plate/Framing

(ASTM A36/ BS EN 10025 )

Angle (ASTM A36/ BS EN

10025 )

Tensile strength Fu := 450 ⋅ MPa Fup := 450MPa

Fu = 65.267⋅ ksi Fup = 65.267⋅ ksi

Yield strength Fy := 345 ⋅ MPa Fyp := 345MPa

Fyp = 50.038⋅ ksi

Fy = 50.038⋅ ksi

Modulus of Elasticity of steel E := 200000MPa

4

E = 2.901 × 10 ⋅ ksi

Grade of Bolts : ASTM A325M (AISC 360-16 Sec J3 and TABLE J3.2)

Allowable tensile strength Fnt := 620MPa Fnt = 620 ⋅ MPa

Fnt = 89.923⋅ ksi Fnt = 89.923⋅ ksi

Allowable shear strength Fnv := 372MPa Fnv = 372 ⋅ MPa

(threads in shear plane)

Fnv = 53.954⋅ ksi Fnv = 53.954⋅ ksi

Grade of Weld : AWS D1.1 Gr. E70 (AISC 360-16 J2.2 and TABLE J2.5)

series FEXX := 480MPa FEXX = 69.618⋅ ksi

LRFD Resistance Factor for Welds ϕw := 0.75

Design Strenght of weld fw := ϕw⋅ 0.6FEXX fw = 216 ⋅ MPa

fw = 31.328⋅ ksi

A ) INPUT DATA :

SECTION :=

i) Profile

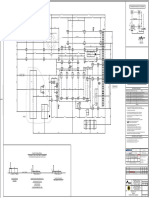

Supported Beam Profile BEAM :=

W 8 x 5.25 x 18

Worksheet

Supported Beam Section Properties

sr_no := vlookup( BEAM , SECTION , 1 ) sr_no = 2 i := sr_no

chk. once if values are

0 0 changing after changing

section sizes

Depth h b := SECTION ⋅ mm h b = 207 ⋅ mm

i, 3

Flange width b fb := SECTION ⋅ mm b fb = 133 ⋅ mm

i, 4

Flange thickness t fb := SECTION ⋅ mm t fb = 8.4⋅ mm

i, 6

Web thickness t wb1 := SECTION ⋅ mm t wb1 = 5.8⋅ mm

i, 5

Distance k r' := SECTION ⋅ mm r' = 8 ⋅ mm

i, 7

Thickness of Web reinforcement Plate t wr := 0mm t wb := t wb1 + 2 ⋅ t wr t wb = 5.8⋅ mm

Supporting Beam Profile BEAM1 :=

W 8 x 5.25 x 18

chk. once if values are

Supporting Beam Section Properties changing after changing

section sizes

(

sr_no1 := vlookup BEAM1 , SECTION , 1 ) sr_no1 = 2

0

j := sr_no1

0

Depth h su := SECTION ⋅ mm h su = 207 ⋅ mm

j,3

Flange width b fs := SECTION ⋅ mm b fs = 133 ⋅ mm

j, 4

Flange thickness t fs := SECTION ⋅ mm t fs = 8.4⋅ mm

j,6

Web thickness t ws := SECTION ⋅ mm t ws = 5.8⋅ mm

j,5

Distance k rs := SECTION ⋅ mm rs = 8 ⋅ mm

j,7

Distance dc d c := h su − 2rs − 2 ⋅ t fs d c = 174.2⋅ mm

>>> kb := 40mm corresponding

dwg.

K of supporting

beam

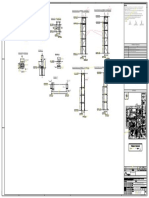

Geometry of Connection "DS"

ii) Bolt Data :

a) Bolt Geometric Data :

Bolt diameter d := 20mm

for W8/ W10 - keep

Diameter of bolt hole Dh := if ( d ≥ 24mm , d + 3mm , d + 2mm) this value = 35 & for all

Dh = 22⋅ mm others as per table

Bolts in Gusset plate :

column number : n xg := 1 x distance : d xg := 0 ⋅ mm Edge distance Le := 35mm

row number : n yg := 2

y distance : d yg := 60⋅ mm

n xg⋅ n yg⋅ d xg ⋅ n xg − 1 + d yg ⋅ n yg − 1

2 2 2 2

Polar Moment of inertia : Ibg :=

Ibg = 18⋅ cm

2

12

Bolts in Beam :

column number n xb := 1 x distance : d xb := d xg

row number : n yb := n yg y distance : d yb := d yg

n xb⋅ n yb⋅ d xb ⋅ n xb − 1 + d yb ⋅ n yb − 1

2 2 2 2

Polar Moment of inertia : Ibb :=

Ibb = 18⋅ cm

2

12

First Bolt distance from top of Steel sb := kb + Le = 75⋅ mm

Check for bolt pitch and edge distance: Check := "OK" if d yb ≥ 3d ∧ Le ≥ 1.5d

1

Check = "OK"

(AISC 360-16, J3.8 and J3.9) "NOT OK" otherwise 1

Checkno_bolts := ( )

"OK" if n yg − 1 ⋅ d yg + 2Le + kb < h b = "OK"

"NOT OK" otherwise

Checkno_bolts = "OK"

up to 5mm differance it is ok

b) Bolt Capacities :

LRFD Resistance factor for fasteners

ϕf := 0.75

(AISC 360-16 (ASD) J3.6 (J3-1) )

π 2

fnv := ϕf ⋅ ⋅ d ⋅ Fnv fnv = 87.65⋅ kN fnv = 19.705⋅ kip

Shear capacity of bolts 4

π 2

fnt := ϕf ⋅ ⋅ d ⋅ Fnt fnt = 146.084 ⋅ kN fnt = 32.841⋅ kip

Tension capacity of bolts 4

iii) Gusset Plate Data :

Gusset plate details: Thickness t g := 10⋅ mm Thickness of horizontal stiffener t stiff := 0mm

Depth h g := h su − 2 ⋅ t fb h g = 190.2⋅ mm

Width b g := if b fs ≤ 200mm , 100mm , 0.5⋅ b fs − t ws

( )

b g = 100 ⋅ mm

Weld details: Gussest plate weld size sw := 8 ⋅ mm

with web of beam

Gussest plate weld size swf := 6 ⋅ mm

with flange of beam

iv) Splice Plate Data :

Splice plate details: Thickness t s := 10⋅ mm

Depth ( )

h s := n yg − 1 ⋅ d yg + 2Le h s = 130 ⋅ mm

Width b s := ( n xb − 1 ) ⋅ d xb + ( n xg − 1 ) ⋅ d xg + 4Le + 10mm b s = 150 ⋅ mm

v) Eccentricities:

Beam bolt x Eccentricity ( )

exb := 0.5⋅ t ws + b g + 10mm + Le + 0.5 n xb − 1 ⋅ d xb exb = 147.9⋅ mm

Gusset plate bolt x Eccentricity exg := 0.5⋅ t ws + b g − Le + 0.5( n xg − 1 ) ⋅ d xg exg = 67.9⋅ mm

Splice plate bolt max x Eccentricity exs := exb exs = 147.9⋅ mm

d yg

y eccentricity

(

ey := 0.5⋅ h b − sb + n yg − 1 ⋅

2

)

ey := ey ey = 1.50⋅ mm

eyb := ey eyg := ey eys := ey

B ) Design Forces (Unfactored) :

Maximum Axial force, T := 5kN

(force taken from staad analysis)

Maximum Shear force, V := 5kN

(force taken from staad analyis)

C ) Calculation of Design Shear strength :

Check for Shear in Bolts

a ) Allowable Shear rest. by beam bolts capacity (considering bolts in double shear)

2 ⋅ fnv

Vrb := Vrb = 69.697⋅ kN

exb⋅ ( n xb − 1 ) ⋅ d xb exb⋅ ( nyb − 1 ) ⋅ d yb

2 2

1

n ⋅n + + Vrb = 15.668⋅ kip

2 ⋅ Ibb 2 ⋅ Ibb

xb yb

b ) Allowable Shear rest. by gusset plate bolts capacity (considering bolts in double shear)

2 ⋅ fnv

Vrg :=

exg⋅ ( n xg − 1 ) ⋅ d xg exg⋅ ( n yg − 1 ) ⋅ d yg

2 2

1 Vrg = 141.691 ⋅ kN

n ⋅n + 2 ⋅ Ibg

+ 2 ⋅ Ibg

xg yg Vrg = 31.853⋅ kip

Check for Bearing capacity at bolt holes in beam web

Resistance Factor for bearing (LRFD) ϕb := 0.75

c) Allowable Shear rest. by beam bearing capacity (AISC 360-16- J3.10 (J3-6 a))

ϕb ⋅ 2.4⋅ Fu ⋅ d ⋅ t wb

Vbb :=

Vbb = 37.357⋅ kN

exb⋅ ( n xb − 1 ) ⋅ d xb exb⋅ ( n yb − 1 ) ⋅ d yb

2 2

1

n ⋅n + +

2 ⋅ Ibb 2 ⋅ Ibb Vbb = 8.398⋅ kip

xb yb

d) Allowable Shear rest. by beam bearing capacity based on clear distance

(AISC 360-16- J3.10 (J3-6 a,6))

Vertical clear Distance

(

Lcvb := min Le − Dh ⋅ 0.5 , d yb − Dh

)( ) Lcvb = 24⋅ mm

ϕb ⋅ 1.2Fu ⋅ Lcvb⋅ t wb

Vbbcv :=

exb⋅ ( n xb − 1 ) ⋅ d xb exb⋅ ( n yb − 1 ) ⋅ d yb

2 2

1

n ⋅n + + Vbbcv = 22.414⋅ kN

2 ⋅ Ibb 2 ⋅ Ibb

xb yb

Vbbcv = 5.039⋅ kip

Check for Bearing capacity at bolt holes in gusset plate

e) Allowable Shear rest. by gusset plate bearing capacity (AISC 360-16- J3.10 (J3-6 a))

ϕb ⋅ 2.4⋅ Fup⋅ d ⋅ t g

Vgb := Vgb = 130.941 ⋅ kN

exg⋅ ( n xg − 1 ) ⋅ d xg exg⋅ ( n yg − 1 ) ⋅ d yg

2 2

1

n ⋅n + + Vgb = 29.437⋅ kip

2 ⋅ Ibg 2 ⋅ Ibg

xg yg

f) Allowable Shear rest. by gusset plate bearing capacity based on clear distance

(AISC 360-16- J3.10 (J3-6 a))

Dh

Vertical clear Distance Lcvg := min d yg − Dh , Le − Lcvg = 24⋅ mm

2

ϕb ⋅ 1.2Fup⋅ Lcvg⋅ t g

Vcvg := Vcvg = 78.564⋅ kN

( ) ( )

2 2

1 exg⋅ n xg − 1 ⋅ d xg exg⋅ n yg − 1 ⋅ d yg

+ + Vcvg = 17.662⋅ kip

n xg⋅ n yg 2 ⋅ Ibg

2 ⋅ Ibg

Check for Bearing capacity at bolt holes in splice plate

g) Allowable Shear rest. by splice plate bearing capacity (AISC 360-16- J3.10 (J3-6 a))

ϕb ⋅ 2.4⋅ Fup⋅ d ⋅ 2 t s

Vsb :=

Vsb = 128.817 ⋅ kN

exb⋅ ( n xb − 1 ) ⋅ d xb exb⋅ ( n yb − 1) ⋅ dyb

2 2

1

n ⋅n + 2 ⋅ Ibb

+ 2 ⋅ Ibb

Vsb = 28.959⋅ kip

xb yb

h) Allowable Shear rest. by Splice plate bearing capacity based on clear distance

Dh

Vertical clear Distance Lcvs := min d yb − Dh , Le − Lcvs = 24⋅ mm

2

ϕb ⋅ 1.2Fup⋅ Lcvs2t s

Vcvs := Vcvs = 77.29⋅ kN

( ) ( )

2 2

1 exb⋅ n xb − 1 ⋅ d xb exb⋅ n yb − 1 ⋅ d yb

n ⋅n + + Vcvs = 17.376⋅ kip

2 ⋅ Ibb 2 ⋅ Ibb

xb yb

i) Allowable Shear rest. by beam web gross area

Safety factor for Shear hb E

ϕv := 1.0 if < 2.24

for I Shaped member (AISC 360-16 (ASD), G2.1a) t wb Fy

0.9 otherwise

(

Vbg := ϕv⋅ 0.6⋅ Fy⋅ h b ⋅ t wb ) Vbg = 248.52⋅ kN

Vbg = 55.87⋅ kip

Resistance Factor for Shear Yielding (LRFD) ϕy := 1.0

Resistance Factor for Shear rupture (LRFD) ϕr := 0.75

j) Allowable Shear rest. by gusset plate gross area (

Vgg := ϕy⋅ 0.6⋅ Fyp⋅ h g⋅ t g ) Vgg = 393.71⋅ kN

Vgg = 88.51⋅ kip

k) Allowable Shear rest. by splice plates gross area ( )

Vsg := ϕy⋅ 2 ⋅ 0.6⋅ t s⋅ h s ⋅ Fyp Vsg = 538.2⋅ kN

Vsg = 120.992 ⋅ kip

l) Allowable Shear rest. by beam web net area

( )

Vbn := ϕr⋅ 0.6⋅ Fu ⋅ h b − n yb⋅ Dh ⋅ t wb

Vbn = 191.444 ⋅ kN

Vbn = 43.038⋅ kip

m) Allowable Shear rest. by gusset plate net area

( )

Vgn := ϕr⋅ 0.6⋅ Fup⋅ h g − n yg⋅ Dh ⋅ t g

Vgn = 296.055 ⋅ kN

Vgn = 66.556⋅ kip

n) Allowable Shear rest. by splice plate net area

( )

Vsn := ϕr⋅ 2 ⋅ t s⋅ h s − n yg⋅ Dh ⋅ 0.6⋅ Fup

Vsn = 348.3⋅ kN

Vsn = 78.301⋅ kip

Check for Block shear of Beam web & splice plate

o ) Allowable Shear rest. by beam web block shear (AISC 360-16,J4.3, eqn. J4-5)

Net area resisting tension Abwnst := ( n xg − 1) ⋅ dxg + Le − ( n xg − 0.5) ⋅ ( Dh) ⋅ twb

2

Abwnst = 139.2⋅ mm

( n yg − 1) ⋅ dyg + Le ⋅ twb

2

Gross area resisting shear Abwgss := Abwgss = 551.0⋅ mm

Net area resisting shear Abwnss := ( n yg − 1 ) ⋅ d yg + Le − ( n yg − 0.5) ⋅ ( Dh ) ⋅ twb

2

Abwnss = 359.6⋅ mm

Resistance Factor for block shear ϕbs := 0.75

(LRFD)

Ubs := 1.0

( ) (

Vbwbs := min 0.6⋅ Fup⋅ Abwnss + Ubs ⋅ Fup⋅ Abwnst ⋅ ϕbs , 0.6⋅ Fyp⋅ Abwgss + Ubs ⋅ Fup⋅ Abwnst ⋅ ϕbs

)

Vbwbs = 119.799 ⋅ kN

Vbwbs = 26.932⋅ kip

p ) Allowable Shear rest. by splice plate block shear (AISC 360-16,J4.3, eqn. J4-5)

Net area resisting tension Asnst := ( n xg − 1 ) ⋅ d xg + Le − ( n xg − 0.5) ⋅ ( Dh ) ⋅ ts

2

Asnst = 240.0⋅ mm

( nyg − 1 ) ⋅ d yg + Le ⋅ ts

2

Gross area resisting shear Asgss := Asgss = 950.0⋅ mm

Net area resisting shear Asnss := ( nyg − 1 ) ⋅ d yg + Le − ( n yg − 0.5) ⋅ ( Dh) ⋅ ts

2

Asnss = 620.0⋅ mm

( ) (

Vsbs := min2 0.6⋅ Fup⋅ Asnss + Ubs ⋅ Fup⋅ Asnst ⋅ ϕbs , 2 0.6⋅ Fyp⋅ Asgss + Ubs ⋅ Fup⋅ Asnst ⋅ ϕbs

)

Vsbs = 413.1⋅ kN

Vsbs = 92.869⋅ kip

q) Allowable Shear rest. by splice plate bending (AISC 360-16,J4.3, eqn. J4-5)

h 3

4⋅ ts

Gross sectional modulus of splice plates s 3

Ssg := ⋅ Ssg = 56333 ⋅ mm

h s 12

h 3

4⋅ ts n yg⋅ d yg ⋅ n yg − 1

2 2

Net sectional modulus of splice plates

Ssn := ⋅

s

− Dh ⋅

Ssn = 44149 ⋅ mm

3

h s 12

12

Ssg Ssn

Vsbd := min ϕbs ⋅ Fyp⋅ , ϕr⋅ Fup⋅

exs exs Vsbd = 98.555⋅ kN

Vsbd = 22.156⋅ kip

Check for weld capacity between gusset plate and beam web

q) Allowable shear restricted by vertical welds capacity

(

Vw := 2.⋅ 0.707⋅ sw h g − 2 ⋅ sw ⋅ fw ) Vw = 425.639 ⋅ kN

Vw = 95.687⋅ kip

Shear Capacity :

(

va := Vrb Vrg Vbb Vbbcv Vgb Vcvg Vsb Vcvs Vbg Vgg Vsg Vbn Vgn Vsn Vbwbs Vsbs Vsbd Vw )

va = ( 70 142 37 22 131 79 129 77 249 394 538 191 296 348 120 413 99 426 ) ⋅ kN

Allowable shear Va := min va ( ) Va = 22.414⋅ kN

Check for shear design ratio :

V

Check := "OK" if ≤1 V

2 Va V = 5 ⋅ kN = 0.223 Check = "OK"

Va 2

"NOT OK" otherwise

D) Calculation of Design Tensile strength :

Check for Shear in Bolts

a) Allowable Tension rest. by beam bolts shear capacity (considering bolts in double shear)

2 ⋅ fnv

Trb := Trb = 333.906 ⋅ kN

eyb⋅ ( n yb − 1 ) ⋅ d yb eyb⋅ ( n xb − 1 ) ⋅ d xb

2 2

1 Trb = 75.065⋅ kip

n ⋅n + +

2 ⋅ Ibb 2 ⋅ Ibb

xb yb

b) Allowable Tension rest. by gusset plate bolts capacity (considering bolts in double shear)

2 ⋅ fnv

Trg := Trg = 333.906 ⋅ kN

( ) ( )

2 2

1 eyg⋅ n yg − 1 ⋅ d yg eyg⋅ n xg − 1 ⋅ d xg

n ⋅n + + Trg = 75.065⋅ kip

2 ⋅ Ibg 2 ⋅ Ibg

xg yg

Check for Bearing capacity at bolt holes in beam web

c) Allowable Tension rest. by beam bearing capacity (AISC 360-16- J3.10 (J3-6 a))

ϕb ⋅ 2.4⋅ Fu ⋅ d ⋅ t wb

Tbb := Tbb = 178.971 ⋅ kN

eyb⋅ ( n yb − 1 ) ⋅ d yb eyb⋅ ( n xb − 1) ⋅ dxb

2 2

1

+ +

Tbb = 40.234⋅ kip

n xb⋅ n yb 2 ⋅ Ibb

2 ⋅ Ibb

d) Allowable Tension rest. by beam bearing capacity based on clear distance (AISC 360-16- J3.10 (J3-6 a))

Dh

Horizontal clear Distance Lcvxb := Le − Lcvxb = 24⋅ mm

2

ϕb ⋅ 1.2Fu ⋅ Lcvxb⋅ t wb

Tbbcv :=

eyb⋅ ( n yb − 1 ) ⋅ d yb eyb⋅ ( n xb − 1) ⋅ dxb

2 2

1

n ⋅n + +

Tbbcv = 107.383 ⋅ kN

2 ⋅ Ibb 2 ⋅ Ibb

xb yb

Tbbcv = 24.141⋅ kip

Check for Bearing capacity at bolt holes in gusset plate

e) Allowable Tension rest. by gusset plate bearing capacity (AISC 360-16- J3.10 (J3-6 a))

ϕb ⋅ 2.4⋅ Fup⋅ d ⋅ t g

Tgb := Tgb = 308.571 ⋅ kN

eyg⋅ ( n yg − 1 ) ⋅ d yg eyg⋅ ( nxg − 1 ) ⋅ d xg

2 2

1 Tgb = 69.37⋅ kip

n ⋅n + 2 ⋅ Ibg

+

2 ⋅ Ibg

xg yg

f) Allowable Tension rest. by gusset plate bearing capacity based on clear distance

(AISC 360-16- J3.10 (J3-6 a))

Dh

Horizontal clear Distance Lcvxg := Le − Lcvxg = 24⋅ mm

2

ϕb ⋅ 1.2Fup⋅ Lcvxg⋅ t g

Tcvg :=

eyg⋅ ( n yg − 1 ) ⋅ d yg eyg⋅ ( n xg − 1 ) ⋅ d xg

2 2

1 Tcvg = 185.143 ⋅ kN

n ⋅n + +

2 ⋅ Ibg 2 ⋅ Ibg

xg yg

Tcvg = 41.622⋅ kip

Check for Bearing capacity at bolt holes in splice plate

g) Allowable Tension rest. by splice plate bearing capacity (AISC 360-16- J3.10 (J3-6 a))

ϕb ⋅ 2.4⋅ Fup⋅ d ⋅ 2 ⋅ t s

Tsb := Tsb = 617.143 ⋅ kN

eyb⋅ ( n yb − 1 ) ⋅ d yb eyb⋅ ( nxb − 1 ) ⋅ d xb

2 2

1 Tsb = 138.739 ⋅ kip

n ⋅n + +

2 ⋅ Ibb 2 ⋅ Ibb

xb yb

h) Allowable Tension rest. by Splice plate bearing capacity based on clear distance

(AISC 360-16- J3.10 (J3-6 a))

Dh

Lcvxs := Le − Lcvxs = 24⋅ mm

Horizontal clear Distance 2

ϕb ⋅ 1.2Fup⋅ Lcvxs2t s

Tcvs := Tcvs = 370.286 ⋅ kN

eyb⋅ ( n yb − 1 ) ⋅ d yb eyb⋅ ( n xb − 1) ⋅ dxb

2 2

1

n ⋅n + 2 ⋅ Ibb

+

2 ⋅ Ibb

Tcvs = 83.244⋅ kip

xb yb

Resistance Factor for Tension Yielding (LRFD) ϕty := 0.9

Resistance Factor for Tension rupture (LRFD) ϕtr := 0.75

ϕty⋅ Fyp

i) Allowable Tension rest. by gusset plate gross area Tgg := Tgg = 563.889 ⋅ kN

1 6 ⋅ eyg

+

h g⋅ t g 2 Tgg = 126.767 ⋅ kip

h g ⋅ tg

ϕty⋅ Fyp

j) Allowable Tension rest. by splice plate gross area Tsg := Tsg = 755.029 ⋅ kN

1 6 ⋅ eys

+

( 2 ⋅ ts⋅ h s) 2 ⋅ t ⋅ h 2

Tsg = 169.737 ⋅ kip

s s

k) Allowable Tension rest. by gusset plate net area

Net area Agn := h g − n yg⋅ Dh ⋅ t g

( ) Agn = 1462.0⋅ mm

2

2 ⋅ t g h g Dh ⋅ n yg⋅ d yg ⋅ n yg − 1

3 2 2

Sgn :=

3

12 − Sgn = 56.129⋅ cm

hg 12

ϕtr⋅ Fup

Tgn :=

eyg Tgn = 474.872 ⋅ kN

1

+

Agn Sgn Tgn = 106.755 ⋅ kip

( )

2

l)Allowable Tension rest. by splice plate net area Ans := 2 ⋅ t s⋅ h s − n yb⋅ Dh Ans = 1720.00 ⋅ mm

ϕtr⋅ Fup

Tsn := Tsn = 548.449 ⋅ kN

1 eys

+

Ans Ssn Tsn = 123.296 ⋅ kip

m) Allowable Tension rest. by Beam Web

( )

Tbn := ϕtr⋅ 0.9⋅ Fu ⋅ h b − n yb⋅ Dh ⋅ t wb

Tbn = 287.165 ⋅ kN

Tbn = 64.557⋅ kip

Check for Block shear of beam web and gusset plate & splice plate

m) Allowable Tension rest. by beam block shear (AISC 360-16,J4.3, eqn. J4-5)

( n yb − 1 ) ⋅ d yb − ( n yb − 1) ( Dh ) twb

2

Net area resisting tension Abntt := Abntt = 220.4⋅ mm

Gross area resisting shear ( )

Abgts := 2 ⋅ n xb − 1 ⋅ d xb + Le ⋅ t wb

Abgts = 406.0⋅ mm

2

Net area resisting shear ( ) (

Abnts := 2 ⋅ n xb − 1 ⋅ d xb + Le − n xb − 0.5 ⋅ Dh ⋅ t wb

)( )

2

Abnts = 278.4⋅ mm

Factor of safety for block shear (ASD) ϕbs = 0.75

Ubs := 1.0

( ) (

Tbbs := min 0.6⋅ Fu ⋅ Abnts + Ubs ⋅ Fu ⋅ Abntt ⋅ ϕbs , 0.6⋅ Fy⋅ Abgts + Ubs ⋅ Fu ⋅ Abntt ⋅ ϕbs

)

Tbbs = 130.761 ⋅ kN

Tbbs = 29.396⋅ kip

n) Allowable Tension rest. by gusset block shear (AISC 360-16,J4.3, eqn. J4-5)

( n yg − 1) ⋅ dyg − ( n yg − 1 ) ( Dh ) ⋅ tg

2

Agntt := Agntt = 380.0⋅ mm

Net area resisting tension

Gross area resisting shear

( )

Aggts := 2 ⋅ n xg − 1 ⋅ d xg + Le ⋅ t g

Aggts = 700 ⋅ mm

2

Net area resisting shear ( ) (

Agnts := 2 ⋅ n xg − 1 ⋅ d xg + Le − n xg − 0.5 ⋅ Dh ⋅ t g

)( )

2

Agnts = 480 ⋅ mm

( ) (

Tgbs := min 0.6⋅ Fup⋅ Agnts + Ubs ⋅ Fup⋅ Agntt ⋅ ϕbs , 0.6⋅ Fyp⋅ Aggts + Ubs ⋅ Fu ⋅ Agntt ⋅ ϕbs

)

Tgbs = 225.45⋅ kN

Tgbs = 50.683⋅ kip

o) Allowable Tension rest. by splice plate block shear (AISC 360-16,J4.3, eqn. J4-5)

( n yg − 1 ) ⋅ d yg − ( n yg − 1) ( Dh ) ⋅ ts

2

Asntt := Asntt = 380.0⋅ mm

Net area resisting tension

( )

2

Gross area resisting shear Asgts := 2 ⋅ n xg − 1 ⋅ d xg + Le ⋅ t s Asgts = 700 ⋅ mm

Net area resisting shear ( ) ( )( )

Asnts := 2 ⋅ n xg − 1 ⋅ d xg + Le − n xg − 0.5 ⋅ Dh ⋅ t s

2

Asnts = 480 ⋅ mm

( ) (

Tsbs := min2 0.6⋅ Fup⋅ Agnts + Ubs ⋅ Fup⋅ Agntt ⋅ ϕbs , 2 0.6⋅ Fyp⋅ Aggts + Ubs ⋅ Fu ⋅ Agntt ⋅ ϕbs

)

Tsbs = 450.9⋅ kN

Tsbs = 101.366 ⋅ kip

Check for weld capacity between gusset plate and beam web

o) Allowable Tension restricted by gusset welds capacity

( ) ( )

Tw := 2.⋅ 0.707⋅ h g − 2 ⋅ sw ⋅ fw⋅ sw + 2 ⋅ 0.5 b fs − t ws fw⋅ swf

Tw = 658.74⋅ kN

Tw = 148.09⋅ kip

Tension Capacity :

(

t a := Trb Trg Tbb Tbbcv Tgb Tcvg Tsb Tcvs Tgg Tsg Tgn Tsn Tbn Tbbs Tgbs Tsbs Tw )

t a = ( 333.9 333.9 179.0 107.4 308.6 185.1 617.1 370.3 563.9 755.0 474.9 548.4 287.2 130.8 225.4 450.9 658.7

Allowable tension Ta := min ta ( ) Ta = 107.383 ⋅ kN

Check for tension design ratio :

T

Check := "OK" if ≤1 T

3 Ta T = 5 ⋅ kN = 0.047 Check = "OK"

Ta 3

"NOT OK" otherwise

Combined Tension & Shear Interaction Ratio :

2 2

V T −3 V T

+ = 5.371 × 10 + = 0.016

2 2 Vsg Tsg

Vrb Trb

V T V T

+ = 0.05 + = 0.044

Vrg Trg Vbn Tbn

(

t a := Trb Trg Tbb T

V T V T

+ = 0.162 + = 0.027

Vbb Tbb Vgn Tgn (

va := Vrb Vrg Vbb V

V T V T

+ = 0.27 + = 0.023

Vbbcv Tbbcv Vsn Tsn

V T V T

+ = 0.054 + = 0.064

Vgb Tgb Vbwbs Tgbs

V T V T

+ = 0.091 + = 0.023

Vcvg Tcvg Vsbs Tsbs

V T V T

+ = 0.047 + = 0.019

Vsb Tsb Vw Tw

V T

+ = 0.078

Vcvs Tcvs

V T

+ = 0.022

Vgg Tgg

2 2

r1 := V + T V + T V + T V + T V + T V + T V

V 2 T 2 Vrg Trg Vbb Tbb Vbbcv Tbbcv Vgb Tgb Vcvg Tcvg Vsb

rb rb

r := max( r1) r = 0.27

Check := "OK" if r ≤ 1

4 Check = "OK"

4

"NOT OK" otherwise

Va

α := α = 0.209 V + a.T < Va Va = 22.414⋅ kN Ta = 107.383 ⋅ kN

Ta

T

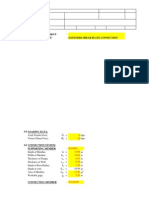

SUMMARY : Check = ( 0 "OK" "OK" "OK" "OK" )

Supported Beam : BEAM = "W 8 x 5.25 x 18"

Va

α = ( 0.209 22.414 )

Supporting Beam : BEAM1 = "W 8 x 5.25 x 18" kN

these are LRFD values, so

values to put as it is in table

You might also like

- Arabian International Company: A.Input DataNo ratings yetArabian International Company: A.Input Data6 pages

- Design of Tank Bottom Beams: CRACK WIDTH CHECK (For Positive Moment)No ratings yetDesign of Tank Bottom Beams: CRACK WIDTH CHECK (For Positive Moment)9 pages

- Anchorage To Concrete Per ACI 318-11 Appendix DNo ratings yetAnchorage To Concrete Per ACI 318-11 Appendix D12 pages

- Steel Connection Design - Tension ElementsNo ratings yetSteel Connection Design - Tension Elements5 pages

- Design of Non Composite Beams With Circular OpeningsNo ratings yetDesign of Non Composite Beams With Circular Openings70 pages

- Base Plate Design Specifications and AnalysisNo ratings yetBase Plate Design Specifications and Analysis19 pages

- Shear Strength Controls 21.65 Kips/bolt: Section at ANo ratings yetShear Strength Controls 21.65 Kips/bolt: Section at A4 pages

- IS 456 vs ACI 318: Structural GuidelinesNo ratings yetIS 456 vs ACI 318: Structural Guidelines15 pages

- "EMBEDPL" Sample Calculation: (4) H.S.A. Example - "EMBEDPL" WorksheetNo ratings yet"EMBEDPL" Sample Calculation: (4) H.S.A. Example - "EMBEDPL" Worksheet5 pages

- WF Base Plate Design Based On AISC Manual 14th Edition (AISC 360-10)100% (1)WF Base Plate Design Based On AISC Manual 14th Edition (AISC 360-10)1 page

- CIDECT 3 - RHS Joint Under Static LoadingNo ratings yetCIDECT 3 - RHS Joint Under Static Loading92 pages

- Sectional Properties of Rolled Steel Joists (Ref: Is: 808 - 1989 & Is: 12778 - 2004)No ratings yetSectional Properties of Rolled Steel Joists (Ref: Is: 808 - 1989 & Is: 12778 - 2004)49 pages

- Client: Project: Estimate No: Contract No: Sheet No: C06/C5/1100% (1)Client: Project: Estimate No: Contract No: Sheet No: C06/C5/18 pages

- "Torsion9" - Simplified Torsion Analysis For Steel Beams: Program DescriptionNo ratings yet"Torsion9" - Simplified Torsion Analysis For Steel Beams: Program Description13 pages

- Compressor Shelter: Load Case-1 Dead LoadNo ratings yetCompressor Shelter: Load Case-1 Dead Load2 pages

- Shear Strength Controls 21.65 Kips/bolt: Section at ANo ratings yetShear Strength Controls 21.65 Kips/bolt: Section at A4 pages

- 21.65 Kips/bolt Shear Strength Controls: Section at ANo ratings yet21.65 Kips/bolt Shear Strength Controls: Section at A3 pages

- AISC 360-10 Beam Splice Connection Analysis100% (2)AISC 360-10 Beam Splice Connection Analysis15 pages

- 10 HOR. BRACE CONNECTION BRACE L90x90x6 - GUSSET PLT.100% (1)10 HOR. BRACE CONNECTION BRACE L90x90x6 - GUSSET PLT.114 pages

- Design of Shear Connection Between Beam To Beam:: As Per AISC 13 Edition (ASD)0% (1)Design of Shear Connection Between Beam To Beam:: As Per AISC 13 Edition (ASD)13 pages

- 4124-Ai-Du-21130i002s01-Is01 (2) - CheckprintNo ratings yet4124-Ai-Du-21130i002s01-Is01 (2) - Checkprint1 page

- 1792-PR002I - IFC - REV01 - Conn Dsn-ConnectionsAssociationTool Report SAP2000 v21 - 0 - 2 - 01 REVNo ratings yet1792-PR002I - IFC - REV01 - Conn Dsn-ConnectionsAssociationTool Report SAP2000 v21 - 0 - 2 - 01 REV316 pages

- SECT."K-K": Port Harcourt Refinery Project Rehabilitation ofNo ratings yetSECT."K-K": Port Harcourt Refinery Project Rehabilitation of1 page

- 1110-BL003I Compressor STEEL HOLD RemovalNo ratings yet1110-BL003I Compressor STEEL HOLD Removal3 pages

- Pedestal Design Load Summary and ReinforcementNo ratings yetPedestal Design Load Summary and Reinforcement3 pages

- Parse 2023 Are The Extant Nursing Theories Endangered SpeciesNo ratings yetParse 2023 Are The Extant Nursing Theories Endangered Species1 page

- North Carolina Test of Algebra I: ReleasedNo ratings yetNorth Carolina Test of Algebra I: Released32 pages

- (Vietnam) Brand Lift Narrative - Updated Dec'17No ratings yet(Vietnam) Brand Lift Narrative - Updated Dec'1715 pages

- Oracle Applications - Functional - Oracle Application Implementation Methodology (AIM)No ratings yetOracle Applications - Functional - Oracle Application Implementation Methodology (AIM)4 pages

- Factors Influencing Employee Retention in Airline IndustryNo ratings yetFactors Influencing Employee Retention in Airline Industry10 pages

- Chapter 5 Dispersion Models (2017!12!29 10-55-04 UTC)No ratings yetChapter 5 Dispersion Models (2017!12!29 10-55-04 UTC)43 pages

- Sapphire Plus Total Flood Fire Suppression System: Features and BenefitsNo ratings yetSapphire Plus Total Flood Fire Suppression System: Features and Benefits2 pages

- Yugoslav Supranational Model in Context of Kardelj'sNo ratings yetYugoslav Supranational Model in Context of Kardelj's6 pages

- 2013 October Reactor Effluent Air Cooler Safety - Through DesignNo ratings yet2013 October Reactor Effluent Air Cooler Safety - Through Design5 pages

- Industrial Entrepreneurs' Memorandum July 2013No ratings yetIndustrial Entrepreneurs' Memorandum July 20133 pages

- Influence of Lubrication On Vibration Response and Surface Roughness in Milling of Aluminum 6061No ratings yetInfluence of Lubrication On Vibration Response and Surface Roughness in Milling of Aluminum 60619 pages

- Symbolic Interaction Ism As Defined by Herbert Blumer67% (6)Symbolic Interaction Ism As Defined by Herbert Blumer15 pages