SLURRY PUMP SELECTION

TRAINING COURSE WMA-06

AIMS

To enable site personnel to understand requirements and

techniques for the correct selection of a Warman Slurry Pump.

Demonstrate selection techniques of pumps and materials.

OBJECTIVES

Participants will be able to:

Understand the components of pump design

Correlate information for pump calculations

Optimise pump selection

Select suitable pump materials

Understand the fundamentals of wear

Work through pump selection example

TRAINING STRATEGY

Participants will be required to attend a seminar of two-day

duration. Day 1 - 8:00AM to 4:30PM

Day 2 - 8:00AM to 4:30PM.

TRAINING REQUIREMENTS

Participants will be required to bring along a calculator (with

square root function as minimum), pen, pencil, eraser and a

ruler.

CONTENT

1 Basic Principles and definitions

1.1 General warnings and safety

1.2 Head vs pressure

1.3 Slurry

1.4 Centrifugal pumps

1.5 Standard nomenclature

1.6 Aeration and snore

1.7 BEP

1.8 Pressure

1.9 Vapour pressure

1.10 Cavitation

1.11 Head

1.12 NPSH

1.13 System Curve

1.14 Discussion

2 Pump Design

2.1 Wet-end construction

2.2 Impeller design and types

2.3 Volute design and types

2.4 Shaft sealing

2.5 Bearing assemblies

2.6 Discussion

3 Pump Duty Calculation

3.1 Classification of slurries

3.2 Viscous slurry identification

3.3 Newtonian slurry calculations

3.4 Student in-class worked example

3.5 Long distance (series, multi-stage) pumping

3.5 Parallel pumping

3.6 Sources of errors

3.7 Class worked example

3.8 Discussion

4 Pump Selection

4.1 Effect of particle size

4.2 Optimisation efficiency

4.3 Drive arrangements

4.4 Power transmission

4.5 Rotation of pump discharge

4.6 Variable speed drives

4.7 Discussion

5 Materials

5.1 White Irons

5.2 Rubbers

5.3 Polyurethanes

5.4 Ceramics

5.5 Composite material

5.6 Technical bulletins

5.7 Material data sheets

5.8 Wear resistance

5.9 Impellers

5.10 Side liners

5.11 Volutes

5.12 Shaft sleeves

5.13 Tip speeds & temperature ratings

5.14 Discussion

6 Wear Fundamentals

6.1 Types of wear

6.2 Corrosion

6.3 Mechanisms of wear

6.4 Wear patterns

6.5 Wear testing

6.6 Solutions to wear

6.7 Discussion

7 Pump Trouble Shooting

7.1 Pump fails to discharge any slurry

7.2 Pump discharges slurry at low flow / head

7.3 Pump discharges slurry at low flow / increased head

7.4 Pump feed hopper overflows

7.5 Excessive pump power consumption

7.6 Pump vibrates or is noisy

7.7 Fault finding chart

7.8 Discussion

8 Examples (Participants to work through and select)

8.1 Application Data Sheet – Worked Example #1

8.2 Application Data Sheet – Student Worked Example (#2)

8.3 Application Data Sheet – Student Worked Example (#3)

8.4 Density Concentration Nomogram

8.5 Darcy’s Friction Factor Nomogram

8.6 Equivalent Lengths of Fittings Table

8.7 Durand’s FL Nomogram

8.8 Modified Durand’s FL Nomogram

8.9 Wilson’s Settling Velocity Nomogram

8.10 HR & ER Nomogram

8.11 Head Losses at Inlet, Contraction & Enlargement

8.12 Application Data Form

8.13 Blank Calculation Sheets

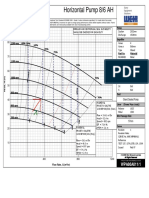

8.14 Performance Curves