0% found this document useful (0 votes)

1K views1 pageProcess Flow Chart

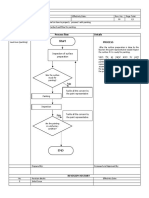

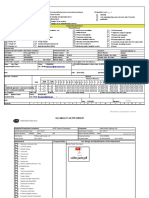

1) The flow chart outlines the quality assurance process for manufacturing power cables from raw materials to the final product.

2) Key steps include testing the purity of aluminum/copper rods, drawing wires to the required diameter, stranding and shaping the conductor, extruding the core with spark tests, laying the core and checking insulation thickness and resistance.

3) Further steps involve armoring the cable with wires/strips, applying inner and outer PVC sheathing that meets standards, conducting final testing and inspection, and certifying the final product.

Uploaded by

AnkurCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

1K views1 pageProcess Flow Chart

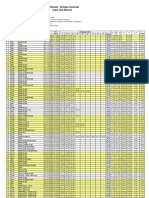

1) The flow chart outlines the quality assurance process for manufacturing power cables from raw materials to the final product.

2) Key steps include testing the purity of aluminum/copper rods, drawing wires to the required diameter, stranding and shaping the conductor, extruding the core with spark tests, laying the core and checking insulation thickness and resistance.

3) Further steps involve armoring the cable with wires/strips, applying inner and outer PVC sheathing that meets standards, conducting final testing and inspection, and certifying the final product.

Uploaded by

AnkurCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd

/ 1