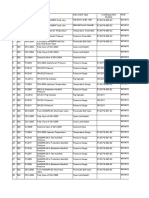

Document No.

:

MMR-DS-60-022-A4

JASA KONSULTASI PENYUSUNAN FEED Rev. No.: 1

UNTUK PENGEMBANGAN TERMINAL BBM MAUMERE - NUSA

TENGGARA TIMUR Page: 1 of 6

INSTRUMENT DATASHEET

FLOW INDICATOR

OWNER : PT. PERTAMINA PATRA NIAGA

PROJECT : JASA KONSULTASI PENYUSUNAN FEED UNTUK

PENGEMBANGAN TERMINAL BBM MAUMERE

LOCATION : MAUMERE - NUSA TENGGARA TIMUR

1 26-Jul-22 RE-ISSUE FOR BID RA IP AS AFW

0 20-May-19 ISSUE FOR APPROVAL AS ANS ND/YM -

PREP’D CHECK’D APPROVED APPROVED

REV DATE STATUS

PT. PERTAMINA PATRA NIAGA

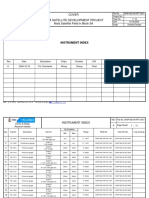

DATA SHEET FOR FLOW INDICATOR

Document No.: MMR-DS-60-022-A

2 OF 4

Rev.: 1 Date: 26-Jul-22

REVISION HISTORICAL SHEET

Rev. Date Description

0 20-May-19 Issued for Approval

1 26-Jul-22 Issued for BID

DATA SHEET FOR FLOW INDICATOR

Document No.: MMR-DS-60-022-A

3 OF 4

Rev.: 1 Date: 26-Jul-22

GENERAL NOTES

1. VTA = Vendor to Advice

2. All Instruments shall be supplied with a 316 SS nameplate with Instrument Tag No. and Model No. permanently inscribed.

3. All item to be painted with suppliers standard paint system suitable for outdoors.

4. Manufacture's documentation to be included, Material Certificates for wetted parts, Hydrotest Report, Installation,

5. Operating & Maintenance Instruction, Spare Part List, Dimensional Drawing.

6. Vendor shall be responsible for correct model selection.

7. All Item to be painted with suppliers standard paint system suitable for outdoors.

8. Operating & Maintenance Instruction, Spare Part List, Dimentional Drawing.

9. Bolt and nuts to be ASTM a 193 GR B7/A 194 GR 2H.

10. Witnessed Pressure/Vacuum Testing are required.

DATA SHEET FOR FLOW INDICATOR

Document No.: MMR-DS-60-022-A

4 OF 4

Rev.: 1 Date: 26-Jul-22

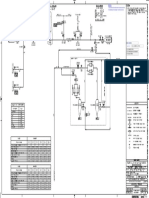

1 Tag No. 10-FI-31

2 Service Oil Catcher System

GENERAL 3 Line No. Equipment No. 20-DR-004-A1A-10" -

4 P&ID No. MMR-DG-10-022

5

6 Fluid State Oil Liquid

7 Design Pressure 15 (*) kg/cm2 g

8 Operating Pressure 8 - 14 (*) kg/cm2 g

9 Design Temperature 60 (*) °C

10 Oprating Temperature 35 (*) °C

11 Minimum 10 (*) m3/hr

FLUID DATA

12 Flowrate Normal 300 - 500 (*) m3/hr

13 Maximum 700 (*) m3/hr

14 Density 996.7 kg/m3

15 Viscosity 0.83 cP

16 Vapour Pressure of Liquid 0.62 Psia

17

18 Pipe End Connection (In / Out) 10 inch

19 Schedule 40

PIPE DATA

20 Pipe material Carbon Steel, API 5L Gr B, ASME B36.10M

21

22 Flow Meter Type Rotameter

23 Process Connection Size Rating 10 inch inch 150# RF - ANSI

24 Inlet Location Bottom - Top (Upward)

25 Type Armored Metal Tube

26 Tube Material Liner Material 316 SS PTFE

27 Float Type Float Material Manufacturer Standard 316 SS

28 Wetted Seal Material Viton

ELEMENT 29 Accuracy 2 % of the full scale

30 Repeatability Rangeability 0.02 - 0.05% 10 : 1

31 Supply Voltage Elect. Connection 24 VDC 1/2 NPT-F

32 Enclosure Class IP 65

33 Hazardous Area Zone 2, Group IIA, T3

34

35

36

37 Output N/A

38 Transmitter Type N/A

TRANSMITTER

39 Transmitter Range N/A

40

41 Calibration Certificate Yes

42 Material Certificate Yes

CERTIFICATE

43 Function Test Yes

44

45 Manufacturer Note-1

46 Model No. VTA

PURCHASE

47

48

Note:

1. VTA = Vendor to be Advice

2. Refer to Company Approved Vendor List.

3. Tag No. shall be marked.

4. N/A = Not Applicable

(*) To be verified during Detailed Engineering Design (DED)