Fleet Management Manual 2020 - FINAL

Uploaded by

Muhammad Rizqi SiregarFleet Management Manual 2020 - FINAL

Uploaded by

Muhammad Rizqi SiregarSCI MANUAL PROCEDURAL COVERSHEET:

Fleet Management Manual

Functional Area: Supply Chain – Fleet Management

Owner (Name & Position) Martin Maina – Global Fleet Manager

Approved by: Willem Zuidema – Global Head of Warehousing, Distribution & Fleet

Approved by:

Approved by:

Date of Approval:

Version: 2020 v1.6

Date for Review:

Languages (inc. hyperlinks): English

Applicable to: Fleet Management Teams

Unique procedure number: NA

REVISION HISTORY

01.1 30th June 2020

Page 1 of 46

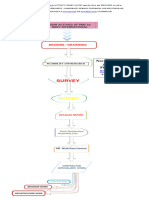

Document Layout

This document designed to follow the flow of typical lifecycle of vehicle from the time it is acquired

and added into the fleet up to the time it is decommissioned and disposed of. It splits into six key

areas:

1. Introduction, Purpose, Scope and Roles & Responsibilities

2. Road Safety

3. Planning, Budgeting and Sourcing of Vehicles

4. Fleet Operations

5. Monitoring and Measuring of Fleet Performance

6. Vehicles Disposal

In addition to these key areas, there is also references to additional documents that provide more

detailed information on specific fleet management topics.

Fleet Manual Model

Page 2 of 46

Table of Contents

Document Layout .................................................................................................................................... 2

Introduction, Purpose, Scope, Roles & Responsibilities ......................................................................... 7

Abbreviations .......................................................................................................................................... 7

Introduction ............................................................................................................................................ 7

Purpose ................................................................................................................................................... 7

Scope ....................................................................................................................................................... 8

Standards, Procedures, Guidelines and Key Tools .................................................................................. 8

Roles and Responsibilities ..................................................................................................................... 10

Responsibilities by Functional Role ............................................................................................... 10

Typical Fleet Management Organogram ....................................................................................... 13

1) Road Safety ................................................................................................................................... 14

PRC01– Road Safety Training & Awareness .......................................................................................... 14

Section 1: Purpose ........................................................................................................................ 14

Section 2: Summary....................................................................................................................... 14

Section 3: Procedural Steps .......................................................................................................... 15

Section 4: Related Documents and Forms ................................................................................... 16

PRC02 – Vehicle Safety Standards ........................................................................................................ 16

Section 1: Purpose ........................................................................................................................ 16

Section 2: Summary....................................................................................................................... 16

2.1 Minimum Vehicle Safety features ............................................................................................ 16

2.2 Vehicle Mechanical Condition................................................................................................. 17

2.3 In-Vehicle Monitoring System (IVMS) ..................................................................................... 17

Section 3: Procedural Steps .......................................................................................................... 17

Section 4: Related Documents and Forms ................................................................................... 18

PRC03 – Safe Journey Management ..................................................................................................... 18

Section 1: Purpose ........................................................................................................................ 18

Section 2: Summary....................................................................................................................... 18

Section 3: Procedural Steps .......................................................................................................... 19

Section 4: Related Documents and Forms ................................................................................... 20

PRC04 – Incidents Reporting and Investigations .................................................................................. 20

Section 1: Purpose ........................................................................................................................ 20

Section 2: Summary....................................................................................................................... 20

Section 3: Procedural Steps .......................................................................................................... 21

Section 4: Related Documents and Forms ................................................................................... 22

2) Planning & Budgeting.................................................................................................................... 23

PRC05 – Planning for Fleet .................................................................................................................... 23

Page 3 of 46

Section 1: Purpose ........................................................................................................................ 23

Section 2: Summary....................................................................................................................... 23

Section 3: Procedural Steps .......................................................................................................... 25

Section 4: Related Documents and Forms ................................................................................... 25

PRC 06 Budgeting for Fleet ................................................................................................................... 26

Section 1: Purpose ........................................................................................................................ 26

Section 2: Summary....................................................................................................................... 26

6.1 Vehicle Fleet’s Costs ............................................................................................................... 26

6.2 Budgeting for New Vehicles ................................................................................................... 26

6.3 Budgeting for fleet operating costs ......................................................................................... 26

Section 3: Procedural Steps .......................................................................................................... 27

Section 4: Related Documents and Forms ................................................................................... 27

3) Sourcing vehicles........................................................................................................................... 28

PRC07 – Vehicle Procurement .............................................................................................................. 28

Section 1: Purpose ........................................................................................................................ 28

Section 2: Summary....................................................................................................................... 28

7.1 Global Framework Agreement ............................................................................................... 28

7.2 Buying Locally .......................................................................................................................... 28

7.3 Buying second hand vehicles ................................................................................................... 28

Section 3: Procedural Steps .......................................................................................................... 29

Section 4: Related Documents and Forms ................................................................................... 29

PRC 08 – Renting Vehicles..................................................................................................................... 29

Section 1: Purpose ........................................................................................................................ 29

Section 2: Summary....................................................................................................................... 29

Section 3: Procedural Steps .......................................................................................................... 30

Section 4: Related Documents and Forms ................................................................................... 30

4) Fleet Operations............................................................................................................................ 31

PRC09 – Managing Drivers .................................................................................................................... 31

Section 1: Purpose ........................................................................................................................ 31

Section 2: Summary....................................................................................................................... 31

9.3 Health and Wellbeing.............................................................................................................. 31

9.2 Training and Development...................................................................................................... 31

9.1 Recruitment ............................................................................................................................ 31

Section 3: Procedural Steps .......................................................................................................... 32

Section 4: Related Documents and Forms ................................................................................... 32

PRC 10 – Maintenance and Repairs ...................................................................................................... 32

Section 1: Purpose ........................................................................................................................ 32

Page 4 of 46

Section 2: Summary....................................................................................................................... 32

10.1 Warranties Protection .......................................................................................................... 33

10.2 Vehicle Tyres......................................................................................................................... 33

10.3 Fleet Maintenance supplies ................................................................................................... 33

Section 3: Procedural Steps .......................................................................................................... 34

Section 4: Related Documents and Forms ................................................................................... 34

PRC11 – Fuel Management ................................................................................................................... 35

Section 1: Purpose ........................................................................................................................ 35

Section 2: Summary....................................................................................................................... 35

Section 3: Procedural Steps .......................................................................................................... 36

Section 4: Related Documents and Forms ................................................................................... 36

PRC12 – Fleet Administration ............................................................................................................... 36

Section 1: Purpose ........................................................................................................................ 36

Section 2: Summary....................................................................................................................... 36

12.1 Motor Vehicle Insurance ....................................................................................................... 37

12.2 Documentation & Records Management.............................................................................. 37

12.3 Management of Vehicle Keys ................................................................................................ 37

12.4 Personal Usage of SCI Vehicle .............................................................................................. 37

12.5 Managing other fleet assets ................................................................................................... 37

12.6 Fleet Staffing .......................................................................................................................... 38

Section 3: Procedural Steps .......................................................................................................... 38

Section 4: Related Documents and Forms ................................................................................... 38

5) Monitor and Measure ................................................................................................................... 39

PRC13 – Reporting and Monitoring ...................................................................................................... 39

Section 1: Purpose ........................................................................................................................ 39

Section 2: Summary....................................................................................................................... 39

13.1 Fleet Tracker Tool ................................................................................................................ 41

13.2 Performance Indicators (Metrics) ..................................................................................... 41

13.3 In-Vehicle Monitoring and Fleet Management Systems .................................................... 41

13.4 Fleet Impact on Environment............................................................................................ 42

Section 3: Procedural Steps .......................................................................................................... 42

Section 4: Related Documents and Forms ................................................................................... 43

6) Vehicle Disposal ............................................................................................................................ 44

PRC14 – Disposal ................................................................................................................................... 44

Section 1: Purpose ........................................................................................................................ 44

Section 2: Summary....................................................................................................................... 44

14.1 Annual Disposal Plans ........................................................................................................... 45

Page 5 of 46

14.2 Developing a Business Case for Vehicle Disposal ................................................................ 45

Section 3: Procedural Steps .......................................................................................................... 45

Section 4: Related Documents and Forms ................................................................................... 46

11

Page 6 of 46

Introduction, Purpose, Scope, Roles & Responsibilities

Abbreviations

ABS Automatic Braking System

BER Beyond Economic Repair

CO Country Office

CO2 Carbon Dioxide

COOM Country Office Operating Model

CSG Child Safeguarding

FMS Fleet Management System

FWA Framework Agreement

GSS Global Safety and Security

HR Human Resources

IVMS In-Vehicle Monitoring System

KM Kilometer

KPI Key Performance Indicator

L/KM Liter per Kilometer

OEM Original Equipment Manufacturer

PRC Procedure

RTA Road Traffic Accident

SC Supply Chain

SCI Save the Children International

SOF Source of Funds

VTS Vehicle Tracking System

Introduction

Save the Children International (SCI) operates a fleet of approximately 1300 vehicles and an estimated

500 rented vehicles (2019) that includes 4x4 vehicles, cars, vans, trucks, generators, boats, motorbikes,

quad bikes, ambulances and armoured vehicles. These assets are high value items and are critical to

our ability to deliver programs and support children. The operating cost related to managing our fleet

is significant, between 30 and 40 M USD per annum over 2018 and 2019.

A well-managed vehicle fleet is instrumental for program effectiveness, our cost performance, the

safety of our staff travelling in the field and the communities we serve. Increasingly, fleet management

can play a role in reducing our carbon footprint though use of cleaner engines in new vehicle types

and the improvement of driving behaviours and skills,

Purpose

Effective fleet management aims to:

Minimize capital costs through effective procurement

Page 7 of 46

Reduce operating costs by providing efficient vehicles and providing access to quality

maintenance

Enhance road safety, protect the environment and finally,

Maximizing disposal values through a managed sales process.

The standards and processes that make up this quality framework will ensure that our organization’s

vehicles are prudently managed throughout their lifespan (i.e. from the time they are acquired to the

time they are disposed).

The aim is to provide safe, cost efficient and environmentally friendly transport solutions to SCI staff.

This is a key enabler to deliver and support programs for children and contribute to the communities

where we operate.

Scope

The minimum standards and guidance provided within this Fleet Management Manual applies globally

to all SCI country programmes that operate fleet vehicles.

"Vehicle" is a general term for any vehicle owned and operated by SCI whether, leased, rented or

borrowed and may include, but is not limited to:

Support vehicle: Vehicle that is used for program operations activities and not charged

exclusively to any project

Project vehicle: Vehicles allocated to just one project and charged to one Source of Fund

(SOF) / Project Award.

Pooled vehicle: Vehicle used across multiple projects and charged to multiple SOFs

Rental vehicle: Vehicle rented from a vehicle rental supplier

Standards, Procedures, Guidelines and Key Tools

Standards Procedures Guidance and Key Tools

Road Safety PRC1: Training & Awareness

PRC2: Vehicle Safety Standards Guideline 2.1 Vehicle Safety Standards

PRC3: Safe Journey Guideline 3.1 Fitness to Drive

Management

Guideline 3.2 Vehicle Speed

PRC4: Incidents Reporting & Guideline 4.1 Vehicle Incidents and Accidents

Investigations Management

Guideline 4.2 Analysing and Investigating

Vehicle Accidents

Plan and PRC5: Fleet Planning Guideline 5.1 Fleet Rightsizing

Budget

Asset Planning Tool

Page 8 of 46

PRC6: Budgeting for Fleet Guideline 6.1 Forecasting and Budgeting for

Fleet Costs

Source PRC7: Vehicle Procurement Guideline 7.1 - Buying Second Hand Vehicles

PRC8: Renting Vehicles Guideline 8.1 – Renting Vehicles

Operate PRC9: Managing Drivers Guideline 9.1 - Drivers Recruitment

Guideline 9.2 - Drivers Training and

Development

Guideline 9.3 - Drivers Health and Wellbeing

Guideline 9.4 – Safeguarding Children in

Vehicles

PRC10: Maintenance & Repairs Guideline 10.1 - Vehicle Maintenance and

Repairs

Guideline 10.3 - Selecting and Controlling

Tires

PRC11: Fuel Management Guideline 11.1 - Monitoring and Controlling

Fuel

Guideline 11.2 - Storage and Handling of Fuel

PRC12: Fleet Administration Guideline 12.1 - Motor Vehicle Insurance and

Risk Management

Guideline 12.2 - Fleet Documentation and

Records Management

Guideline 12.5 - Managing other Fleet Assets

Monitor & PRC13: Monitoring and Guideline 13.1 - Reporting and Measuring

Measure Reporting Fleet Performance Performance

Guideline 13.2 – In Vehicle Monitoring and

Management System

Dispose PRC14: Vehicle Disposal Guideline 14.1 Vehicle Disposal

Page 9 of 46

Roles and Responsibilities

Roles and responsibilities of staff members are outlined in a matrix called a “RASCI Matrix”. RASCI

stands for Responsible, Accountable, Supporting, Consulted, and Informed. These are defined as:

Responsible A person who is responsible for executing the process or activity. This person does the

process or activity.

Accountable A person who is accountable for ensuring the process or activity being carried out

successfully. This person will have Yes/No/Veto decision powers.

Supporting A person who provides support to ensure that the activity is carried out.

Consulted A person that needs to feedback and contribute to the activity.

Informed A person who should be made aware that the activity is being carried out or an action is

being taken.

The RASCI is based on a generic team structure, and whilst the exact positions or job titles may not

exist in all programmes, the responsibilities will need to be allocated to the equivalent relevant person

or delegated as appropriate.

All vehicle management activities must fully comply with all applicable SCI policies and procedures.

The responsibilities set out in this section are based on what would be considered a standard team

structure for a SCI operational programme. While job titles and staffing numbers will vary between

countries, it is essential these responsibilities are delegated and acted upon.

Responsibilities by Functional Role

Country Director The Country Director as the ultimate budget holder for Country

Office operations and is Accountable for ensuring that the Fleet

Management operations has sufficient financial and

administrative support to provide a safe working environment

and compliance with Fleet Management procedures, and

national transport regulations and legislations. These can be

delegated to the Supply Chain Director or Director of Operations

and therefore Responsible for their implementation.

1) To ensure the SCI fleet is operated safely and efficiently in accordance with these procedures.

2) Ensure local transport policy, guidance and operating procedures are in place covering all road

transport compliance requirements, including driver licencing, and use and allocation of vehicles

within country of operation.

3) Ensure fleet size and composition is appropriate and justified in line with programme needs and to

secured funding is in place to cover the running costs of the fleet.

4) Ensure standardisation of the fleet across the programme appropriate to local context and

environment.

5) Set up In-Country a multi-disciplinary Road Safety Working Group – RSWG (HR, Safety and

Security, Fleet)

6) Procurement and disposal of vehicles is carried out in line with SCI policies.

Page 10 of 46

7) Ensure that all road traffic incidents are duly investigated in accordance to the SCI road safety

policy and procedures. Root cause analysis of crash incidents is duly conducted and corrective

measures are identified and implemented.

Supply Chain Director / Supply Chain / Operations Director is accountable to the Country

Operations Director Director for ensuring that the fleet management operations have

sufficient financial and administrative support to provide a safe

working environment, compliance with SCI procedures, national

laws and regulations.

1) Overall responsibility for the entire country fleet operations. Analyse the effectiveness of operations.

2) Develop costs and budget to cover transport needs and ensure programme managers and budget

holders are consulted in the budgeting process.

3) Maintain accurate fleet inventory records accounting for all live fleet assets (including fleet assets

that are not in service such as ‘Beyond Economic Repair” (BER) and that correct disposal policy is

complied with for all fleet elements.

4) Responsible for ensuring that road safety procedures and adhered to and all vehicle accidents are

duly reported in DATIX system. Follow up on all vehicle accidents ensuring correct reporting and

appropriate actions taken.

5) Determine replacement and disposal schedules of vehicles accordingly.

6) Ensure office has up to date versions of SCI policies including fleet procedures and that all staff are

aware and understand them.

CO Head of Supply Chain

1) Maintain compliance with SCI fleet policies and procedures.

2) Ensure correct utilisation and allocation of fleet across the programme.

3) Review monthly fleet performance reports lead the fleet function team with continuous

improvement plans.

4) Ensure drivers are trained in SCI policies, procedures, first aid, care of their vehicles, use of vehicle

in off road conditions and daily servicing.

5) Ensure planned preventative maintenance (daily checks and scheduled services) are carried out to

a high standard with minimum disruption to programme activities.

6) Regular checks to test how well fleet safety rules and standards are being implemented and adhered

to by staff

Fleet Coordinator / Manager

1) Day-to-day management of the fleet (vehicles, bikes, boats, generators, etc) assigned to operations.

2) Ensure vehicles have correct equipment and sufficient fuel for the planned trip.

3) Collate transport requests and complete daily and weekly movement plan and update daily vehicle

movement and service board and ensure vehicles are tracked when away from base.

4) Ensure rental vehicles are fit for purpose and that hired drivers have an acceptable level of skills

and are briefed on SC policies, code of conduct and Child Safeguarding principles.

5) Ensure rented vehicles’ and driver’s contracts are complete and correct.

6) Collate and analyse all fleet data and forward to Head of Supply Chain in accordance with set time

lines.

Page 11 of 46

7) Maintain and update all required records and paperwork for vehicles and drivers.

8) Manage drivers and mechanics and ensure there is in place a timetable to manage driving hours.

Field Manager

1. Liaise with fleet team on vehicle needs when developing project proposal and annual planning.

2. Ensure program activities are coordinated and that vehicle pooling system is used in vehicle routes

scheduling and that maintenance of vehicles is carried out in a timely manner.

3. Authorising all journeys, ensure adequate safety and security checks have been carried out prior to

departure and that the situation is monitored throughout the journey as necessary.

4. Is Accountable for compliance of fleet procedures at the field office level.

Budget Holder / Programme Manager

1) Complete weekly vehicle work schedule for logistics and prepare and approve transport requests

of their teams.

2) Ensure all programme staff under their responsibility utilise vehicles appropriately and in line with

policies and procedures.

Mechanic (In-house Repairs & Maintenance)

1) Responsible for the maintenance and repair of all vehicles, generators, boats, etc

2) Carry out repairs and maintenance as required.

3) Inspect any work that is contracted out to other workshops.

4) Record all work and costs for each vehicle in log books and vehicle files.

5) Maintain workshop and tools in a safe and clean condition.

6) Carry out vehicle damage assessments upon RTA’s occurring.

7) Report any faults that are not repaired and any damage caused by user error to the

logistics/transport officers.

Driver

1) Abide by all SCI driving rules and transport policies.

2) Maintain proper in-vehicle records, ensure all trips are signed off by passengers

3) Ensure all equipment allocated to the vehicle is complete and in good working order, including spare

tyres and communications equipment (radios, satellite phones etc), before undertaking any journeys.

4) Ensure route is approved and relevant security staff aware accordingly.

5) Before commencing on a journey, ensure that the vehicle is in good working condition, clean (inside

and out), appropriately equipped and has adequate fuel for the intended journey.

6) Adhere to the Guidelines on Safeguarding Children in Vehicles

A driver is defined as a member of personnel, who drives any vehicle for work purposes (including

personnel whose primary task is driving, and all other members of staff whilst driving for work purposes).

A vehicle includes vehicles owned, leased or rented and private vehicles whilst being used for work

purposes.

Page 12 of 46

Regional Head of Supply Chain

1) Review and provide feedback on monthly fleet reports to respective Country offices in their region.

2) Accountable to ensure CO’s are submitting monthly fleet reports in a timely manner

3) Support CO’s

o Annual fleet planning and budgeting

o Reviewing and approving business cases for vehicles disposal

4) Consulted by CO’s for any new vehicle procurement by reviewing and approving business cases.

Typical Fleet Management Organogram

This is a typical model of a CO fleet management structure. There are several factors including CO-specific context and

the size of operations that will influence the right structure. Refer to PRC 12 for more information on how to determine

the right size of staff required to manage the existing size of fleet hat is based on the Supply Chain Country Office

Operating Model

Page 13 of 46

1) Road Safety

“Aid can be delivered more effectively and safely when resources are not diverted towards managing the

consequences of vehicle accidents, not to mention of the human cost.”

Any collision involving an Organization’s vehicle, even though minor, involves potential serious

personal injury, and affects the safety and wellbeing of our employees and other road users. Such road

accidents and incident can adversely affect and compromise the organization’s image and reputation.

Save the Children International takes this very seriously.

Traffic accidents happen for several reasons such as mechanical failure (lack of maintenance or failure

in materials), weather conditions (fog, rain, humidity or lighting), or road conditions (holes, cracks,

sinking or obstacles), but mostly is due to human error causing about 70% of traffic accidents – most

common causes being lack of experience, driving under the influence of alcohol or drugs, driving while

tired or sleepy, distractions, speeding or not following traffic signals.

The key objective is to reduce the risk of harm to employees and others, reduce the number of

incidents, reduce costs and to meet all legal requirements of health & safety legislation.

The standards and guidelines provided in this manual are anchored on the 5 pillars that are closely

aligned with the current UN road safety approach, namely;

Pillar 1 Pillar 2 Pillar 3 Pillar 4 Pillar 5

Road Safety Safe Road Post-Crash

Safe Driving

Safer Vehicles Response &

Management Users Environment

Investigations

PRC01– Road Safety Training & Awareness

Unique procedure number SCI_SC_FLT_PRC 01

Section 1: Purpose

SCI uses road safety awareness and training as one of the key elements to bring about the required

behavioural change and in embedding a road safety culture within the organization.

Section 2: Summary

The most positive change to road user behaviour occur when road safety legislation is supported

by strong and sustained enforcement, and public awareness. The objective is to promote a

heightened level of safety awareness and responsible driving behaviour – “Moving from Compliance

to Culture” by:

Providing for managerial and technical approaches to improve awareness of road safety and

the improvement of behaviours and attitudes

Page 14 of 46

Instilling a sense of collective and individual responsibility amongst the staff in promoting

road safety

Holding ourselves and others accountable in taking the necessary measures to reduce road

traffic accidents.

Ensuring drivers are aware that the standards expected of SCI should be adhered to at all

times irrespective of the in-country standards and capacity.

Evaluate and Record data on all road traffic fatalities and injuries for monitoring

Monitor country-level trends.

Conduct root-cause analysis of road incidents

Share impact of road incidents and consequences to raise awareness

among all staff

Evaluate and assess the implementation of road safety programs to

determine whether the expected results are being achieved and where

adjustments are needed.

Communicate Raise awareness through awareness campaigns on safe road user behaviour

Develop a communications plan to ensure a consistent dissemination of

road safety information and education to staff. Use of audio and visual

aids e.g. posters, video presentations road safety emails to all staff etc.

In country briefings must include road safety awareness, including types

of vehicle used, types of weather conditions and any special

requirements, general road safety advise based on context.

Ensure that all drivers are regularly reminded of their obligations with

respect to the use and physical safety of Save the Children vehicles

Participate and engage all staff during the annual road safety week

campaigns.

Design training and awareness campaigns that are supported by a

lessons-learned system

Train All drivers are properly trained and certified with defensive driving

courses and require periodic recertification every two years. (refer to

Guidelines on Driver Training and Development for more information)

Mandatory Road Safety Awareness Training for all SCI staff

Section 3: Procedural Steps

Procedural Step Job Role Timeframe Deliverable

Responsible or Output

Identify Training Needs (Assess) in

consultation with the Global Fleet Manager and CO Fleet On-going Training

1

the Global Safety and Security team. Coordinator basis Needs

Page 15 of 46

Procedural Step Job Role Timeframe Deliverable

Responsible or Output

Prepare CO Annual Training Program (include Annual

Head of Supply

2 required resources) Training

Chain

program

Regional Review and inputs Regional Supply

3

Chain Lead

Section 4: Related Documents and Forms

1 GLD 9.1 Drivers Training and Development Required (New)

PRC02 – Vehicle Safety Standards

Unique procedure number SCI_SC_FLT_PRC 02

Section 1: Purpose

SCI vehicles (owned or rented) that they are appropriately equipped and maintained for safe use.

Section 2: Summary

SCI operated vehicles (owned or rented) must meet the highest of national and international safety

standards. Roadworthy vehicles are those that are fit for use and therefore must comply with

standard vehicle safety requirements.

The three critical factors of vehicle safety are the:

1. Vehicle Safety Standards

1.1. Minimum Vehicle Safety Features

1.2. Vehicle Mechanical Conditions

2. In-Vehicle Monitoring System

2.1 Minimum Vehicle These are the standard inbuilt vehicle features that are either fitted by

Safety features the vehicle manufacturer (original equipment manufacturer, OEM) or

as additional aftermarket features and modifications done to enhance

safety and to ensure that the vehicle is suited for specific tasks or road

conditions.

All SCI operated vehicles must meet the following minimum safety features:

a) Seat-belts and seat-belt anchorage: Vehicles should be fitted with 3-point safety seat belts. Every

passenger seat (front and back) must have a functioning seat belt.

b) Anti-Lock Braking System (ABS): Electronic stability control prevents skidding and loss of control

in cases of oversteering or understeering.

c) In Vehicle Monitoring System: SCI vehicles will be fitted with In-Vehicle Monitoring System

d) Tyres (refer to PRC 10.3 of the Fleet Management Manual on controlling tyres) for minimum

safety requirements.

Page 16 of 46

e) Airbags (driver and front passenger)

f) SCI prohibits fitting and/or use of bull bars on vehicles.

2.2 Vehicle Mechanical In order to operate and maintain an efficient and safe fleet, vehicles

Condition require to be serviced and maintained to the highest standard and in

accordance with the manufacturer’s specification and in the established

period.

a) Ensure quality replacement parts are used on all vehicles, particularly for safety-critical elements

such as brakes or tyres.

b) Monitor the durability of parts and any vehicle defects that occur.

c) Ensure timely maintenance of vehicles should defects occur or be identified.

In addition to this, the designated driver must be able to check for obvious vehicle defects prior to and

during every trip.

Mandatory pre-journey inspections to ensure the vehicle is in a safe and roadworthy condition

before commencing the journey.

Inter-trip check after a schedule rest period. This is to ensure that the vehicle is still roadworthy

for the remainder of the journey.

Post-trip check at the end of the trip. Checking for and reporting any faults that may have arisen

during the journey.

Ensure those responsible for maintenance are aware of detected defects.

Ensure all defects are repaired prior to a vehicle being used for any future assignment.

Maintenance work must be regularly assessed to ensure it is of high standard.

2.3 In-Vehicle The use of vehicle tracking system (VTS, provides data points on safety and

Monitoring System security control of fleet: real time positioning, trip history, speed, geofencing

(IVMS) etc. The key objectives of using tracking system includes:

To manage poor driving behaviours and practices such as excessive

speed, long driving hours, unauthorised use or unauthorised routes

To improve the security of personnel and assets by tracking vehicle

locations especially in high risks environment.

Reduction in Accidents resulting to fatalities, liabilities, asset damage/loss

Monitoring of driver behaviour

Mitigate security and safety risks exposure e.g. carjacking, vehicle theft

1) All Save the Children vehicles are to be fitted with suitable IVM/FMS. For new vehicles, the system is

to be installed at the point of purchase or prior to use.

2) The fleet coordinator to discuss with individual results with the drivers, which stimulates drivers desire

to be the best and improve performance.

3) Road Safety Working Group (RSWG) to conduct quarterly checks of road usage data

Section 3: Procedural Steps

Procedural Step Job Role Timeframe Deliverable

Responsible or Output

Before

Fleet

Contracting,

Pre-inspect rented vehicles before contracting Coordinator /

with regular Inspection

1 to ensure they meet safety and security Safety &

review report

standards Security Focal

during rental

Point

period

Page 17 of 46

Procedural Step Job Role Timeframe Deliverable

Responsible or Output

Fleet

Coordinator /

Check existing vehicles in fleet and ensure Inspection

2 Safety & As required

equipped with safety equipment report

Security Focal

Point

Driver

Monitor and review driver behaviour data and CO Head of Weekly

3 performance

discuss with individual drivers Supply Chain review

review

Section 4: Related Documents and Forms

1 GLD 2.1 Vehicle Safety Standards New

2 GLD 13.1 In Vehicle Monitoring and Fleet Management System New

PRC03 – Safe Journey Management

Unique Procedure Number SCI_SC_FLT_PRC 03

Section 1: Purpose

Vehicle trips are planned and coordinated with consideration of the safety of passengers the vehicle and the

driver.

Section 2: Summary

Forward planning is a key element to safer journeys. Both journey scheduling and route planning

should consider the following.

Reduce Distances – by consolidating and pooling transport requests.

Manage drivers’ hours – No driver should be required to drive continuously for more

than 2 hours without at least a 15-minute break. Breaks and break locations should be

planned in advance.

Optimise schedules - Ensure journey schedules allow sufficient time for drivers to take

account of reasonably foreseeable weather and traffic conditions and to comply with

speed limits. Schedules should seek to reduce night driving and avoid those times of day

when falling asleep at the wheel is more likely.

Avoid driving in adverse conditions - Actively discourage driving in adverse weather

conditions, particularly fog, very high winds, ice, snow or flooding or where there is a

danger of staff being stranded in remote locations.

Safe journey management is a both a collective and individual responsibilities for all those involved

in the planned journey.

Page 18 of 46

Fleet Ensure journeys are well planned and communicated

Coordinator Ensure the vehicle is in a safe, road-worthy condition and adequately

equipped for the planned trip / journey.

the driver has been adequately prepared to undertake the trip including

advance notice.

Driver Ensure he/she is Fit to Drive for the planned journey. The driver must

not operate a vehicle at any time when his/her ability to do so is

impaired, affected, or influenced by alcohol, illegal drugs, prescribed or

over-the-counter medication, illness, fatigue, or injury.

Drive vehicle:

o professionally and with utmost care by being courteous on the

road

o adhere to traffic rules

o Maintain appropriate Speed by considering the road

conditions, surrounding environment and other traffic and

road users.

Carry out pre- and post-trips vehicle checks and report any mechanical

faults for repairs

Regular check-ins with office during trips to update on vehicle and staff

status. Comply with any specific in-country safety and security

requirements during trips.

Make stops during long trips to rest and provide passengers with

convenient breaks as may be necessary.

It is critical that drivers have the ability to refuse to operate an unsafe vehicle

without reprisal from management.

Passengers Wear seatbelts throughout the journey while in the vehicle

Respect the driver and avoid distracting or giving instructions to the

driver that could compromise their safety

Speak up when the driver is not adhering to traffic rules, over speeding

or endangering lives by his/her driving behaviour.

Be on time for departures.

Be A Safe Passenger!

Safety & Provides security briefs to driver and passengers where necessary

Security Review route plans and schedules and advise on safety and security

requirements on specific routes and/or journeys

In insecure context, review and approve all trips and route plans.

Notify fleet coordinator on any changing safety and security situations

that may affect vehicles and staff while out on the road or field trips.

Section 3: Procedural Steps

Procedural Step Job Role Timeframe Deliverable

Responsible or Output

Advance journey planning; Weekly vehicle Fleet Weekly

1 Weekly

movement plan Coordinator Fleet Planner

Allocate vehicles and assign drivers to planned Fleet Vehicle

2 Daily

trips. Coordinator Scheduling

Page 19 of 46

Procedural Step Job Role Timeframe Deliverable

Responsible or Output

Inspection

3 Carry out pre-trip vehicle inspection Assigned Driver Before Trips

Checklist

Advance notification to requestors on Fleet

4

assigned vehicle and travel schedule Coordinator

Safety &

Prior approval of trips by Safety and Security

5 Security Focal Before Trips

(where applicable)

Point

Section 4: Related Documents and Forms

1 GLD 3.1 Fitness to Drive New

2 GLD 3.2 Vehicle Speed New

3 Drivers Handbook Required

4 Code of Conduct Required

PRC04 – Incidents Reporting and Investigations

Unique procedure number SCI_SC_FLT_PRC 04

Section 1: Purpose

CO’s have in place mechanisms to prevent road crashes and to ensure that they are appropriately

reported and consequently managed by investigating, analysing and taking required corrective

actions when they occur.

Section 2: Summary

Pre-Crash Management – CO’s have in place mechanisms to prevent road crashes by:

Put in place a multi-disciplinary Road Safety Working Group

Carries out Road Safety Risk Assessment and develops a Road Safety Action Plan

Post-Crash Management – Actions to take when an accident occurs will include

Reporting

Investigations and Root Cause Analysis

Consequence Management

The Vehicle Incident and Accident Management Guidelines provide for intervention measures to

put in place in order to reduce cases of preventable accidents and what actions are to be taken in

the case of an accident.

Page 20 of 46

Section 3: Procedural Steps

Pre-Crash Management

Procedural Step Job Role Timeframe Deliverable

Responsible or Output

Set up In-Country a multi-disciplinary Road

Safety Working Group (RSWG) comprising of Road Safety

Country

1 HR, Safety and Security, Fleet or as it may be Working

Director

determined by the CO Senior Management Group

Team

Road Safety Risk Assessment

Identify risks (past incidents and Road Safety

S&S and Fleet Quarterly

2 trends) Risk

Team reviews

Determine Impact Assessment

Identify control measures

Develop Road Safety Action Plan in line with

the Road Safety Strategy

Road safety Awareness campaigns CO Road

Annual with

3 Trainings RSWG Safety

quarterly

Set Annual targets for reducing Action Plan

review

incidents and accidents (measuring

success)

Crash and Incidents Management

Procedural Step Job Role Timeframe Deliverable

Responsible or Output

At the Scene:

Gather information on relevant forms

Incident

Document incidents on relevant Immediate at

Driver / fleet reports in

4 templates the accident

coordinator designated

Immediate reporting / notify Safety scene

templates

and Security Focal point and Fleet

Coordinator

After the Accident

Accident

Submit accident reports on DATIX Fleet

Within 24 Reports

5 system Coordinator /

hours DATIX

Follow up on police reports Focal point

Notify Insurance

Comprehensive Investigations and

Consequence Management

Within 2

Root cause analysis Findings

Road Safety weeks from

6 Recommend any disciplinary or Action

Working Group date of

remedial action in consultation with Plan

accident

the CO HR.

Remedial actions

Page 21 of 46

Section 4: Related Documents and Forms

1 GLD 4.1 Vehicle Incidents and Accidents Management New

2 GLD 4.2 Analysing and Investigating Vehicle Accidents New

3 FL17 – Accident Reporting Template Required

4 FL 18 – Accident Follow Up Report Template Required

5 Crash and Incident Analysis Form Required (New)

Page 22 of 46

2) Planning & Budgeting

The fleet function is a critical component of supply chain that enables the organization to effectively

deliver quality programs and it involves a significant amount of SCI finances to:

Acquire vehicles

o Buying own vehicles based on the need to scale up on our fleet capacity to meet growing

programs transport demand or, as part of the SCI’s vehicle replacement plan,

o Renting of vehicles to meet short-term fleet demands or during emergencies.

Operate and maintain owned vehicles throughout their economic life.

Managing fleet will therefore require resources that includes staff, vehicles and funds to maintain a fit

for purpose fleet. Without proper planning and budgeting for fleet, it is not possible to establish how

many and what type of vehicles and fleet operating costs that would be required. These costs will need

to be forecasted and included in Country Office’s Annual Plan and Master Budget to ensure they are

adequately provided for. It is important that fleet operating costs are built in the longer-term awards.

This section provides a guide to Country program and fleet managers to:

a) Plan for Fleet by:

i. Identifying Transport needs: comparing current and anticipated future transport

demand with existing fleet capacity

ii. Defining fleet requirements: selecting the most suitable type and number of vehicles.

b) Budget for Fleet by:

i. Establishing the total cost of acquiring new vehicles, and

ii. Estimate the annual fleet operating costs including vehicle replacement

The choice of purchasing, renting or leasing should be made at proposal stage taking in consideration:

Needs of the project (Numbers; specifications; security; availability; etc.)

Cost (short and long term)

Internal and External Regulations (Donors requirements, laws in country)

PRC05 – Planning for Fleet

Unique procedure number SCI_SC_FLT_PRC 05

Section 1: Purpose

County Programs have the right fleet capacity for their program transportation needs that is

adaptable to changing operational circumstances.

Section 2: Summary

The number and types of vehicles in the fleet should directly relate to the actual and/or planned

operational requirements. In doing so, the Country Programs will be able to identify the fewest

number of vehicle configurations that can meet the requirements of the widest range of

transportation needs.

Page 23 of 46

The Asset Planning Tool assists the fleet manager with a simplified step-by-step method of

calculating the optimal number and type of vehicles based on assessed transport needs against the

current fleet capacity.

The Fleet Rightsizing Guidelines provides a pragmatic approach that Country Programs can use to

ensure that their fleet is appropriately sized with the right number and types of vehicles required

to meet the needs of the operations.

It helps to answer two main questions:

1) Which vehicles do we need?

2) How many vehicles do we need?

Depending on changes in the program transport needs, rightsizing might actually mean having to:

i. Add new vehicles to the fleet in order to meet increasing transport demands

ii. Reduce number of vehicles in the fleet due to reduction in program operations or phasing

out of emergency response activities.

iii. Replace

a. Older for new vehicles in order to sustain the fleet capacity based on the SCI’s

vehicle retention and replacement plan.

b. Type of vehicles due to change in fleet requirements (e.g. bigger engines with

smaller) for town run or due to environmental considerations (e.g. hybrid vehicles)

Good Practices:

Page 24 of 46

Plan early: Start planning your vehicle needs at least six to eight months ahead based on a

needs assessment to make sure that the need for a vehicle is justified.

Plan vehicle replacement – all vehicles over five years old and/or have reached cumulative

mileage of 150,000km, will be systematically phased out.

Section 3: Procedural Steps

Procedural Step Job Role Timeframe Deliverable

Responsible or Output

Annual

CO Head of Reviews,

1 Organise annual fleet optimisation review Q1

Supply Chain Next Year

Fleet Plans

Manual roll-

Ensure each member has read guidelines on out, Staff

CO Head of

2 Fleet Rightsizing and familiarised themselves onboarding

Supply Chain

with the Asset Planning Tool Induction,

ongoing basis

Fleet Annual with

Consult programmatic leads over programme Fleet Needs

3 Coordinator / Quarterly

transportation needs for each office location. Assessment

HoSC reviews

Create annual fleet optimisation report and Annual Fleet

CO Head of Annual

4 send to CO Operational Lead for review and Performance

Supply Chain Reviews

approval Evaluation

Emergency

Plan for fleet scale up / down during and post CO Head of On Need Transport

5

emergencies Supply Chain Basis Needs

Assessment

Section 4: Related Documents and Forms

Document Title Usage

1 GLD 5.1 - Fleet Rightsizing New

2 Asset Planning Tool Required (New)

Page 25 of 46

PRC 06 Budgeting for Fleet

Unique procedure number SCI_SC_FLT_PRC 06

Section 1: Purpose

Provides guidance to the CO’s fleet managers and Supply Chain leads to ensure that fleet operating

costs are:

a) Proper forecasted

b) Adequately resourced by including in the CO annual budget

c) Monitored and Controlled

Section 2: Summary

Budgeting process should be linked to the country office Finance procedures and Scheme of

Delegation

6.1 Vehicle Fleet’s Costs

Fleet operational costs are mainly grouped into two:

1) Capital Costs: expenses associated with buying of new vehicles

2) Operating Costs: expenses related to the use of a vehicle during its economic life e.g. fuel,

maintenance, repairs, disposals.

The budgeting requirements for new awards must include all fleet vehicle replacement requirements

that may ensue within the life of a project or programme, for example, a 5-year project may involve

fleet vehicles meeting SCI replacement policy mid-way through the programme.

6.2 Budgeting for New Vehicles

Cost of buying new vehicles should to include other related costs such as

a) Shipping and handling charges linked to the delivery of vehicle (for international

procurements)

b) In-country taxes and customs duties (where applicable)

c) Additional accessories and fittings, applied software or equipment to meet specific vehicle

standards

6.3 Budgeting for fleet operating costs

Key things to remember when forecasting operating costs

Fuel, maintenance and repairs costs are of most significant

Average cost is expressed as operating cost per kilometre driven ($/Km)

Costs tend to increase over time and with engine wear

Local inflations will affect current and future price (consult with finance how to factor this

in your budget).

Costs are best controlled through accurate monitoring (refer to PRC 12 on Monitoring and

Measuring Fleet Performance)

The Guidelines on Forecasting and Budgeting Fleet Costs enable fleet managers to:

Page 26 of 46

i. Know and identify different vehicle’s fixed costs: Capital and Operating Costs

ii. Better forecast, budget, monitor and control vehicle operating costs

Section 3: Procedural Steps

Budget Process and Responsibilities by Role

Procedural Step Job Role Timeframe Deliverable

Responsible or Output

Annual

Head of Supply Fleet Costs

Analysing annual spend on vehicle fleet with

1 Chain / Ops Spend

operating costs quarterly

Director Analysis

reviews

Fleet Needs

Identify annual fleet requirements: new

Head of Supply Assessment,

acquisitions, disposals, operating costs.

2 Chain / Ops Annual Fleet plans,

Cost analysis and business case to justify

Director Disposal

new vehicle acquisition plans

Head of Supply Annual fleet

3 Draw annual fleet budget

Chain / Director Budget

Supply Chain

Director/Head,

Finance Director, Approved

4 Budget review and approvals

Awards Manager, Budget

Regional Supply

Chain Lead

Section 4: Related Documents and Forms

Document Title Usage

1 GLD 6.1 - Forecasting and Budgeting for Fleet Costs New

2 CO Finance Manual Required

3

4

Page 27 of 46

3) Sourcing vehicles

The sourcing and procurement of vehicles lies with the Procurement Unit. It is important for the Fleet

and Procurement functions to work in close collaboration to ensure that the right vehicles are

procured in the most cost-effective and timely manner. The decision on where to buy from will be

determined by several factors including availability of funds, donor-specific requirements, vehicle

specifications and requirement, government restrictions etc.

PRC07 – Vehicle Procurement

Unique procedure number SCI_SC_FLT_PRC 08

Section 1: Purpose

SCI vehicles are sourced and procured using the most cost-efficient manner and the process

complies with the procurement procedures and donor requirements

Section 2: Summary

This section provides guidelines on three critical considerations when buying vehicles

i. Buying Internationally through the Global Framework Agreement

ii. Buying locally

iii. Buying of second-hand vehicles

7.1 Global Framework Agreement

Save the children have a global Framework Agreement (FWA) with Toyota Gibraltar (TGS), for the

supply of different vehicle categories that the CO’s may require to meet different transport

requirements.

This is the primary source of vehicles for all Country Offices. Alternative sources will require prior

review and approval by the Regional Supply Chain Lead and the Global Fleet Manager.

7.2 Buying Locally

As Save the Children have international agreements with vehicle providers in place, local

procurement would only be expected to be happening where it makes economic sense, i.e. it is less

expensive, to do so or there are importation restrictions. In such situations;

a) Carry out a cost benefit analysis and a business case to justifying the need to by locally

a) Comply with the procurement procedures and any donor requirements (if donor-funded)

b) Ensure manufacturers’ warranties are valid through the local dealer / supplier.

c) The vehicle meets the minimum requirements Vehicle and Safety Standards

7.3 Buying second hand vehicles

Save the Children do not recommend buying of second-hand vehicles and only in very exceptional

cases would they be approved on a case by case considerations and must be approved by the global

fleet manager. It is important to note that donors do not generally accept purchase of use vehicles.

Page 28 of 46

Buying a used car comes with certain risks do not always have the same safety nets you would have

if you buy a new car. Therefore, there are many things to consider before making your final choice

about what vehicle to buy.

The guidelines on buying of second-hand vehicles provide logical steps of the car-buying journey

from choosing where to buy from to what to check when selecting the vehicle to buy.

Section 3: Procedural Steps

Procedural Step Job Role Timeframe Deliverable

Responsible or Output

Put a Business Case with justification for CO Head of On a need Business

1

buying a used vehicle Supply Chain basis Case

Develop Requirements and Specifications of CO Head of On need

2 Specifications

the vehicle to be purchased Supply Chain basis

OPS director,

Review and approval of the Business Case and RO HoSC,

3 As required

Specifications Global Fleet

Manager

Section 4: Related Documents and Forms

GLD 2.1 – Vehicle Safety Standards New

GLD 7. 2 Buying Second hand Vehicles Revised

PRC 08 – Renting Vehicles

Unique procedure number SCI_SC_FLT_PRC 07

Section 1: Purpose

Provides guidance on key considerations when to rent vehicles and how to comply with vehicle and

operational safety requirements.

Section 2: Summary

Save the Children relies on its own vehicles for its transport needs. However, there are times that

programmes may rent vehicles to meet additional transport capacity. Renting vehicles should be

exceptional on a need-basis under certain situations:

a) To meet additional short-term transport needs (less than six months)

b) Where procuring vehicles would not be appropriate e.g. safety and security considerations

c) On the onset of an emergency response.

d) Meet transport needs requiring specific type and size of vehicles not available from own

fleet e.g. armoured cars, ambulances.

A cost analysis must always be performed to justify the renting of vehicles.

The guidelines on Renting of vehicles enables the fleet manager to:

1) Evaluate and determine the most suitable type of rental arrangements

Page 29 of 46

o Renting vehicle with or without a driver

o Renting vehicle with or without fuel

2) Ensure that rented vehicles meet the SCI’s minimum vehicle safety standards.

3) Follow procurement procedures when renting vehicles and.

4) Ensure that contracts or rental agreements set out responsibilities of both parties, and the

terms and conditions of renting vehicles such as;

o Type and condition of vehicles

o Use of vehicles

o Insurance and liabilities

o Repairs and maintenance

o Drivers

Long term rental agreements (more than six months) must be reviewed and approval by Regional

Head of Supply Chain and the Global Fleet Manager.

Drivers of rented vehicles should be taken through the SCI Code of Conduct, Child Safeguarding

policies, and Safety and Security.

Section 3: Procedural Steps

Procedural Step Job Role Timeframe Deliverable

Responsible or Output

Fleet manager / Annual Fleet Annual

1 Identify and evaluate the need to rent vehicles

Coordinator Planning Fleet Plan

Review and approve requests to rent vehicles Head of Supply On need

2

(for rentals not exceeding 6 months) Chain basis

Regional SC

Review and approve long term rental

4 lead, Global As required

agreements (exceeding 6 months)

Fleet Manager

Pre-qualification and contracting of service FWA /

Procurement

3 providers. Setting up FWA. Use standard As required Rental

Unit

Rental Agreement / Contract Contracts

Manage and monitor rented cars during rental Fleet

4

duration coordinator

Head of Supply

5 Monitor and Review CO rental costs Quarterly

Chain

Section 4: Related Documents and Forms

1 GLD 8.1 – Buying Second Hand Vehicles Revised

2 GLD7.2. – Vehicle Safety Standards New

Page 30 of 46

4) Fleet Operations

Fleet management encompasses a range of functions such as vehicle maintenance, vehicle tracking,

driver and fuel management. Proper fleet management will enable CO’s to organize and coordinate

their fleet in order to increase efficiency, manage safety and security of assets and people, and monitor

and control fleet operating costs.

PRC09 – Managing Drivers

Unique procedure number SCI_SC_FLT_PRC 09

Section 1: Purpose

Sets out the standards and guidelines for effective management of drivers and ensure that drivers

are adequately supported in order to perform their duties diligently and professionally.

Section 2: Summary

Driving is a professional job that requires great skills and competencies. Our drivers are very

important and valuable as they contribute to the successful delivery of our mandate and mission.

We have entrusted them with the responsibility of driving our vehicles that are not only expensive

but carry significant safety and security risks, that, if not properly managed, can have a huge negative

impact on our work and reputation.

Drivers also help to promote our values as good ambassadors while on duty. It is important that

our drivers are respected by ensuring that they are well trained and equipped with the right tools

and resources in order for them to perform their duties with diligence and professionalism. Training

and management of drivers is an important fleet activity that will help to maintain the condition and

optimise the working life of the vehicles. Encouraging and educating our drivers on behaviours

expected of them when handling both the vehicles and deliverables is important.

It is therefore important that a thorough recruitment process is carried out to hire skilled and

competent drivers, train, develop and recognize them and, ensure their health and wellbeing during

their employment.

This section provides the following guidelines that cover key important aspects of managing drivers

9.1 Recruitment 9.2 Training and

Development 9.3 Health and Wellbeing

Eligibility

Competencies Motivation Fitness to Drive

Fitness Standards Recognition Driving hours

Background Check Manage Performance Managing Fatigue

Safety Training programs Medical check ups

Drivers Recruitment Drivers Training and Drivers Health and

Development

Wellbeing

Page 31 of 46

Section 3: Procedural Steps

Procedural Step Job Role Timeframe Deliverable

Responsible or Output

Develop clear job descriptions for drivers that

Head of Supply Driver Job

1 is suitable for the expected level of required As required

Chain Description

skills, safety and security

Driver

Carry out tests to assess driver competence Fleet During

2 Assessment

and skills using set forms and tools Coordinator recruitment

Report

Training

Identify drivers training needs – general and Fleet

3 As required Needs

specific for individual drivers Coordinator

Assessment

Define means and criteria of recognizing Head of Supply Driver

4 As required

drivers Chain Recognition

Define CO-specific procedures of ensuring Fleet

5 As required

drivers’ health and safety. Coordinator

Section 4: Related Documents and Forms

1 GLD 9.1 - Driver Recruitment Revised

2 GLD 9.2 - Drivers Performance and Training New

3 GLD 9.3 - Drivers Health and Wellbeing New

4 GLD 3.1 – Fitness to drive New

5 Driver Recruitment Checklist New

6 Commentary Driver Assessment New

7 Recognising Drivers Recommended (New)

PRC 10 – Maintenance and Repairs

Unique procedure number SCI_SC_FLT_PRC 10

Section 1: Purpose

Save the Children vehicles are maintained in serviceable and operational conditions in accordance

with the manufacturers’ recommendations and the best industry practices.

Section 2: Summary

In order to operate and maintain an efficient fleet, vehicles require to be serviced and maintained

to the highest standard and in accordance with the manufacturer’s specification and in the

established period. The operating procedure for preventative maintenance is vital to ensuring that

vehicles are serviced and maintained at the correct time.

The objective of Maintenance and Repairs Guidelines is to ensure that:

1) Vehicles are serviced and maintained to the highest standard and in accordance with the

manufacturer’s specification and at the recommended intervals.

a. Preventative maintenance and servicing

Page 32 of 46

b. Repairs both mechanical and body works.

2) Repairs are to be carried out by competent and qualified mechanics using the correct

vehicle parts as recommended by manufacturers, whether this is done in-house or

contracted out. In terms of an external workshop there are three main options available

for such facilities:

a. A large commercial workshop, which may in fact be a main dealer or large local

repairer.

b. A small independent workshop / repairer.

c. Where large humanitarian aid agencies are also operating in the country, they may

have workshop facilities that can be used.

3) Consider setting up a Service Contract or FWA with a suitable garage for your fleet by

following the standard SCI Procurement policies and procedures. Ensure to clearly define

the minimum technical criteria for selecting a service provider depending on the scope of

services and works.

4) Manufacturers warranties are protected

5) SCI vehicles MUST not be “cannibalized” for spares to repair other vehicles.

10.1 Warranties Protection

Warranties are only valid if maintenance and service schedules are:

Done according to the manufacturers’ instructions

Carried out by a competent and qualified service provider

Used genuine and right vehicle parts and fluids

Supported by proper records and documentation

10.2 Vehicle Tyres

Tyres can be up to 15-20% of the variable operational costs, and between 3-5% of the direct costs

through the entire vehicle’s life. The goal of choosing the tire’s brand and model is to minimize the

cost per kilometre/mile, preserving minimum-safety conditions. Tyres are also critical to the safety

of your vehicle. The Guidelines on Selecting and Controlling Tyres provides comprehensive

requirements and instructions to be followed in tyres management.

a) Selecting Tyres

b) Controlling tyres

c) Replacing tyres

d) Safe disposal of used tyres

10.3 Fleet Maintenance supplies

Keep some basic stock, e.g. fluids for topping up, light bulbs, fuses, windscreen wiper blades,

fire extinguishers etc. (even if all servicing and repair is contracted out)

Volume of stocks should be kept to minimum to minimize wastage and obsolescence.

Where quality spare parts are not available locally, volume of spare parts should be held in

stock based on lead time and consumption rate.

Avoid keeping spare parts where locally available. Identify reliable supplier following

procurement procedures.

Follow warehouse procedures and practices in managing fleet supplies. This may be delegated to

warehouse for segregation of duties.

Page 33 of 46

Section 3: Procedural Steps

Procedural Step Job Role Timeframe Deliverable

Responsible or Output

Fleet

Fleet

1 Put in place vehicle maintenance schedules As required Maintenance

Coordinator

Schedule

Identify and contract reputable repairs Procurement

2 As required FWA/Contract

garages Unit

Put in place SOPS for requesting vehicle Head of Supply

3 As required SOPs

repairs and management of spare parts Chain

Accurate

Recording and reporting of repair and SC officer / Every Maintenance

4

maintenance costs fleet officer transaction and Repair

Costs

Fleet

5 Monthly audit of vehicle parts held in stock Monthly Stock reports

Coordinator

Update fleet tracker with repair and SC officer /

6 Weekly Fleet Tracker

maintenance information fleet officer

Section 4: Related Documents and Forms

1 GLD 10.1 - Maintenance and Repairs Revised

2 GLD 10.2 - Operating Inhouse Vehicle Workshop New

3 GLD 10.3 - Selecting and Controlling Tires New

4 FL13 - Fleet Maintenance Request Form Required

5 MAINTENANCE SCHEDULE Toyota Land Cruiser Recommended

6 MAINTENANCE SCHEDULE Toyota Hilux Recommended

7 MAINTENANCE SCHEDULE Toyota Corolla Recommended

8 TGS Tire Guide Recommended

Page 34 of 46

PRC11 – Fuel Management

Unique procedure number SCI_SC_FLT_PRC 11

Section 1: Purpose

Provide guidelines and operating procedures to ensure efficient management of fuel that includes

availability, controlling and monitoring fuel consumption as well as ensuring occupational safety in

fuel storage and handling.

Section 2: Summary

Fuel constitutes about 70% - 80% of the variable operating costs. Country Programs should

therefore put adequate measures to control fuel consumption in order to eliminate misuse and

minimize wastage of fuel.

The fleet manager / coordinator is responsible for controlling of fuel and fuel usage by ensuring that

a) Controls are in place for monitoring consumption rate of allocated fleet

b) Fuel Stock and/or supply is closely controlled and monitored to ensure availability, prevent

losses and control quality.

c) Regular audits of fuel consumption and transactions are carried out and any anomalies are

investigated and corrective actions taken.

Sourcing of fuel Use reputable suppliers to ensure fuel Availability and Quality

Follow procurement procedures to identify fuel suppliers (pump

stations).

Framework Agreement should be established with specific supplier

(s) in which the terms for fuel supply are clearly defined.

Controlling fuel Use of Fuel Cards where possible with pump stations

transactions Use of Fuel Oil Vouchers (should be booklets printed in triplicate,

carbonated) – must be used to approve all fuel fillings

Avoid use of cash transactions

Apply warehouse practices to control fuel stock (where applicable)

Monthly reconciliations of fuel transactions and stock take

Storing and handling Safe working practices

fuel

Fuel as flammable and combustible liquid shall be stored and

handled in a manner that minimizes the potential for fire hazards

and complies with applicable safety standards and local regulations.

Storage containers and rooms shall meet rigorous construction

and fire rated design specifications.

Proper handling procedures to avoid fuel contamination

GLD 11.2 - Storage and Handling of Fuel

Monitoring fuel Fuel consumption rates will depend on vehicle types and other

consumption factor such as road conditions, weather, vehicle age and more

importantly, by driving habits.

o How to Calculate Fuel Consumption

Page 35 of 46

o Causes of fuel over consumption

o Improving vehicle fuel economy

o Vehicle scheduling and route planning

o Driver behaviour

o Vehicle condition

Section 3: Procedural Steps

Procedural Step Job Role Timeframe Deliverable or

Responsible Output

Put in place fuelling procedures and Head of Supply As Fuelling SOPs

1

schedule Chain required and Schedule

Fleet

2 Verify and sign off fuel receipts Daily

Coordinator

Monthly fuel transactions reconciliations.

Fleet Reconciliation

3 Invoices from suppliers against approved Monthly

Coordinator reports.

fuel vouchers.

Fuel stock take where on-site storage is Fleet

4 Monthly Stock Reports

used Coordinator

Approved Fuel

Approve all fuel reports and investigate any Head of Supply