1

NEHRU INSTITUTE OF TECHNOLOGY

Kaliyapuram, Coimbatore – 641 105

ME8381

COMPUTER AIDED MACHINE DRAWING

LABORATORY MANUAL

2017 REGULATIONS

II YEAR

DEPARTMENT OF MECHANICAL ENGINEERING

2

ANNA UNIVERSITY SYLLABUS

ME 8381 COMPUTER AIDED MACHINE DRAWING L T P C

0 0 4 2

OBJECTIVES:

To make the students understand and interpret drawings of machine components

To prepare assembly drawings both manually and using standard CAD packages

To familiarize the students with Indian Standards on drawing practices and

standard components

To gain practical experience in handling 2D drafting and 3D modelling software

systems.

UNIT I DRAWING STANDARDS & FITS AND TOLERANCES 12

Code of practice for Engineering Drawing, BIS specifications – Welding symbols,

riveted joints, keys, fasteners – Reference to hand book for the selection of standard

components like bolts, nuts, screws, keys etc. - Limits, Fits – Tolerancing of

individual dimensions – Specification of Fits – Preparation of production drawings

and reading of part and assembly drawings, basic principles of geometric

dimensioning & tolerancing.

UNIT II INTRODUCTION TO 2D DRAFTING 16

Drawing, Editing, Dimensioning, Layering, Hatching, Block, Array, Detailing,

Detailed drawing.

Bearings - Bush bearing, Plummer block

Valves – Safety and non-return valves.

UNIT III 3D GEOMETRIC MODELING AND ASSEMBLY 32

Sketcher - Datum planes – Protrusion – Holes - Part modelling – Extrusion – Revolve

– Sweep – Loft – Blend – Fillet - Pattern – Chamfer - Round - Mirror – Section -

Assembly

Couplings – Flange, Universal, Oldham’s, Muff, Gear couplings

Joints – Knuckle, Gib & cotter, strap, sleeve & cotter joints

Engine parts – Piston, connecting rod, cross-head (vertical and horizontal), stuffing

box, multi-plate clutch

Miscellaneous machine components – Screw jack, machine vice, tail stock, chuck,

vane and gear pump

TOTAL:60 PERIODS

3

Total: 20% of classes for theory classes and 80% of classes for practice

Note: 25% of assembly drawings must be done manually and remaining 75% of

assembly drawings must be done by using any CAD software. The above tasks

can be performed manually and using standard commercial 2D / 3D CAD

software

OUTCOMES:

Upon the completion of this course the students will be able to

CO1 Follow the drawing standards, Fits and Tolerances

CO2 Re-create part drawings, sectional views and assembly drawings as per

standards

TEXT BOOK:

1. Gopalakrishna K.R., “Machine Drawing”, 22nd Edition, Subhas Stores

Books Corner, Bangalore, 2013

4

CONTENTS

Experiment Faculty

Date Title of Experiment Marks

Number Signature

S1 -

S2 -

10

11

12

13

14

5

UNIT I

DRAWING STANDARDS & FITS AND TOLERANCES

Code of practice for Engineering Drawing, BIS specifications – Welding symbols,

riveted joints, keys, fasteners – Reference to hand book for the selection of standard

components like bolts, nuts, screws, keys etc. - Limits, Fits – Tolerancing of

individual dimensions – Specification of Fits – Preparation of production drawings

and reading of part and assembly drawings, basic principles of geometric

dimensioning & tolerancing.

6

Preferred drawing sheet sizes (First choice) ISO-A Series

Location of Title block

Details in Title block

7

Study

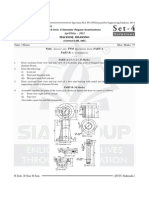

Experiment 1 DRAWING STANDARDS

Date:

Code of practice for Engineering Drawing:

BIS specifications:

To provide the correct information about the drawings to all the people concerned, the

drawings must be prepared, following certain standard practices, as recommended by

Bureau of Indian Standards (BIS).

BIS; SP–46: 1988

Sheet sizes

The basic principles involved in arriving at the sizes of drawing sheets are:

(a) X : Y = 1 : √2 , (b) XY = 1

where X and Y are the sides of the sheet.

Title block

The title block should lie within the drawing space such that, the location of it,

containing the identification of the drawing, is at the bottom right hand corner.

Scales

Scale is the ratio of the linear dimension of an element of an object as represented in

the drawing, to the real linear dimension of the same element of the object itself.

Wherever possible, it is desirable to make full size drawings, so as to represent true

shapes and sizes. If this is not practicable, the largest possible scale should be used.

While drawing very small objects, it is advisable to use enlarging scales.

Dimensioning

A drawing of a component, in addition to providing complete shape description, must

also furnish information regarding the size description. These are provided through the

distances between the surfaces, location of holes, nature of surface finish, type of

material, etc. The expression of these features on a drawing, using lines, symbols,

figures and notes is called dimensioning.

8

Drawing Sheet Layout

Dimensioning

9

Dimension is a numerical value expressed in appropriate units of measurement and

indicated on drawings, using lines, symbols, notes, etc., so that all features are

completely defined.

Sections

In order to show the inner details of a machine component, the object is imagined to

be cut by a cutting plane and the section is viewed after the removal of cut portion.

Sections are made by at cutting planes and are designated by capital letters and the

direction of viewing is indicated by arrow marks.

Hatching is generally used to show areas of sections. (Thin lines at 45º)

Riveted joints

Riveted joints are permanent fastenings and riveting is one of the commonly used

method of producing rigid and permanent joints. Manufacture of boilers, storage

tanks, etc., involve joining of steel sheets, by means of riveted joints.

A rivet is a round rod of circular cross-section. It consists of two parts, viz., head and

shank. Mild steel, wrought iron, copper and aluminium alloys are some of the metals

commonly used for rivets.

Keys

Keys are machine elements used to prevent relative rotational movement between a

shaft and the parts mounted on it, such as pulleys, gears, wheels, couplings.

For making the joint, grooves or keyways are cut on the surface of the shaft and in the

hub of the part to be mounted. After positioning the part on the shaft such that, both

the keyways are properly aligned, the key is driven from the end, resulting in a firm

joint.

Keys are classified into three types, viz., saddle keys, sunk keys and round keys.

Fasteners

A machine element used for holding or joining two or more parts of a machine or

structure is known as a fastener.

The fasteners are of two types: permanent and removable (temporary). Riveting and

welding processes are used for fastening permanently. Screwed fasteners such as

bolts, studs and nuts in combination, machine screws, set screws, etc., and keys

10

Welding symbols

11

12

Basic size deviation and tolerancing

Tolerancing the dimensions

Schematic representation of Fit

13

Study

Experiment 2 FITS AND TOLERANCES

Date:

Introduction

The manufacture of interchangeable parts requires precision. Precision is the degree of

accuracy to ensure the functioning of a part as intended. Experience shows that it is

impossible to make parts economically to the exact dimensions.

Limits, Fits, Tolerancing of individual dimensions

The two extreme permissible sizes between which the actual size is contained are

called limits. The maximum size is called the upper limit and the minimum size is

called the lower limit.

The permissible variation of a size is called tolerance. It is the difference between

the maximum and minimum permissible limits of the given size. If the variation is

provided on one side of the basic size, it is termed as unilateral tolerance.

Similarly, if the variation is provided on both sides of the basic size, it is known as

bilateral tolerance.

Basic Size is determined solely from design calculations. If the strength and

stiffness requirements need a 100mm diameter shaft, then 100mm is the basic

shaft size.

Specification of Fits

The relation between two mating parts is known as a fit. Depending upon the actual

limits of the hole or shaft sizes, fits may be classified as clearance fit, transition fit and

interference fit.

Clearance fit - It is a fit that gives a clearance between the two mating parts.

Transition fit - This fit may result in either interference or a clearance, depending

upon the actual values of the tolerance of individual parts.

If the difference between the hole and shaft sizes is negative before assembly; an

interference fit is obtained.

14

Clearance fit

Transition fit

15

Interference Fit

16

17

Experiment 1 PREPARATION OF PRODUCTION DRAWING

Date:

Aim:

To draft the given 2D drawing manually

Tools used:

Drafter, Drawing kit

Procedure:

1. Fix the drawing sheet in the drawing board

2. Mount the drafter

3. Sketch the layout and title block as per the standard

4. Draw the given drawing with the help of Drafter and the kit

5. Mention the dimensions

Result:

18

UNIT II

INTRODUCTION TO 2D DRAFTING

Drawing, Editing, Dimensioning, Layering, Hatching, Block, Array, Detailing,

Detailed drawing.

Bearings - Bush bearing, Plummer block

Valves – Safety and non-return valves.

19

CATIA 2D COMMANDS (Toolbars)

CATIA (Computer Aided Three-dimensional Interactive Application)

It is a multi-platform CAD / CAM / CAE. It is written in the C++ programming

language.

A set of tools that helps us to create and constrain 2D geometries

The Sketcher workbench contains the following standard workbench specific toolbars

Profile toolbar

The commands located in this toolbar allow creating simple geometries and more

complex geometries

Operation toolbar

This toolbar contains the commands such as trim, mirror, chamfer that are used to

modify the created profile.

Constraint toolbar

Profiles may be constrained with dimensional (distances, angles) or geometrical

(tangent, parallel) constraints using the commands in the Constraint toolbar

20

INTRODUCTION TO 2D DRAFTING - 1

2D Drawing - 1

2D Drawing - 2

21

Experiment 2 INTRODUCTION TO 2D DRAFTING - 1

Date:

Aim:

To draft the given 2D drawing using CATIA V5.20 software

Tools used:

Sketcher, Profile, etc.

Procedure:

1. Click the Sketcher icon to start the Sketcher workbench.

2. Select XY, YZ, ZX plane to define the sketch plane, now the Sketcher

workbench is displayed, it contains the tools needed for sketching any profile.

3. Select the profile and draw the part which is given in the model.

4. Using Constraint command the dimensions are modified as per the given model.

5. Exit the Sketcher workbench

6. The final 2D model is created.

Result:

22

INTRODUCTION TO 2D DRAFTING - 2

2D Drawing - 3

2D Drawing - 4

23

Experiment 3 INTRODUCTION TO 2D DRAFTING - 2

Date:

Aim:

To draft the given 2D drawing using CATIA V5.20 software

Tools used:

Sketcher, Profile, etc.

Procedure:

1. Click the Sketcher icon to start the Sketcher workbench.

2. Select XY, YZ, ZX plane to define the sketch plane, now the Sketcher workbench

is displayed, it contains the tools needed for sketching any profile.

3. Select the profile and draw the part which is given in the model.

4. Using Constraint command the dimensions are modified as per the given model.

5. Exit the Sketcher workbench

6. The final 2D model is created.

Result:

24

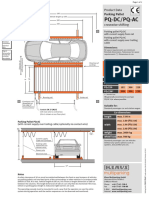

BEARINGS

Bush Bearing

Plummer Block

25

Experiment 4 BEARINGS

Date:

Aim:

To draft the given 2D drawing of Bearings using CATIA V5.20 software

Tools used:

Sketcher, Profile, etc.

Procedure:

1. Click the Sketcher icon to start the Sketcher workbench.

2. Select XY, YZ, ZX plane to define the sketch plane, now the Sketcher workbench

is displayed, it contains the tools needed for sketching any profile.

3. Select the profile and draw the part which is given in the model.

4. Using Constraint command the dimensions are modified as per the given model.

5. Exit the Sketcher workbench

6. The final 2D model is created.

Result:

26

VALVES

Safety Valve

Non-Return Valve

27

Experiment 5 VALVES

Date:

Aim:

To draft the given 2D drawing of Bearings using CATIA V5.20 software

Tools used:

Sketcher, Profile, etc.

Procedure:

1. Click the Sketcher icon to start the Sketcher workbench.

2. Select XY, YZ, ZX plane to define the sketch plane, now the Sketcher workbench

is displayed, it contains the tools needed for sketching any profile.

3. Select the profile and draw the part which is given in the model.

4. Using Constraint command the dimensions are modified as per the given model.

5. Exit the Sketcher workbench

6. The final 2D model is created.

Result:

28

UNIT III

3D GEOMETRIC MODELING AND ASSEMBLY

Sketcher - Datum planes – Protrusion – Holes - Part modelling – Extrusion – Revolve

– Sweep – Loft – Blend – Fillet - Pattern – Chamfer - Round - Mirror – Section -

Assembly

Couplings – Flange, Universal, Oldham’s, Muff, Gear couplings

Joints – Knuckle, Gib & cotter, strap, sleeve & cotter joints

Engine parts – Piston, connecting rod, cross-head (vertical and horizontal), stuffing

box, multi-plate clutch

Miscellaneous machine components – Screw jack, machine vice, tail stock, chuck,

vane and gear pump

29

CATIA V5

3D COMMANDS

After the completion of the 2D profile, exit the Sketcher Workbench.

The 2D profile can be converted into 3D with the help of the following toolbars.

Sketch-Based Features

Pad, Pocket, Shaft commands are located in the toolbar to convert the 2D profile into

3D.

Dress-Up Features

Edge Fillet, Chamfer, Shell commands are located in the toolbar to enhance 3D

drawings

Transformation Features

Translation, Mirror, Pattern forming commands are present in the toolbar

30

COUPLINGS 1

Flanged Couplings

Universal Coupling

31

Experiment 6 COUPLINGS 1

Date:

Aim:

To draft the given 2D drawing of Couplings into 3D using CATIA V5.20 software

Procedure:

1. Select the XY plane

2. Enter the Sketcher Workbench

3. Sketch the profile of the part without considering the dimensions

4. Constrain the profile to match the dimensions as given

5. Exit the Sketcher Workbench, return to the Part Design Workbench

6. Click Pad and give the thickness for the part

7. Similarly select another plane or define a new plane using plane tool that is

offset with XY, YZ, and ZX plane

8. Enter Sketcher to define the sketch and give the required padding.

9. Make similar sketches followed by pocket command to cut the slots

10. Capture the image of the part so obtained

Result:

32

COUPLINGS 2

Oldham Coupling

Muff Coupling

33

Experiment 7 COUPLINGS 2

Date:

Aim:

To draft the given 2D drawing of Couplings into 3D using CATIA V5.20 software

Procedure:

1. Select the XY plane

2. Enter the Sketcher Workbench

3. Sketch the profile of the part without considering the dimensions

4. Constrain the profile to match the dimensions as given

5. Exit the Sketcher Workbench, return to the Part Design Workbench

6. Click Pad and give the thickness for the part

7. Similarly select another plane or define a new plane using plane tool that is

offset with XY, YZ, and ZX plane

8. Enter Sketcher to define the sketch and give the required padding.

9. Make similar sketches followed by pocket command to cut the slots

10. Capture the image of the part so obtained

Result:

34

JOINTS 1

Knuckle Joint

Gib and Cotter Joint

35

Experiment 8 JOINTS 1

Date:

Aim:

To draft the given 2D drawing of Joints into 3D using CATIA V5.20 software

Procedure:

1. Select the XY plane

2. Enter the Sketcher Workbench

3. Sketch the profile of the part without considering the dimensions

4. Constrain the profile to match the dimensions as given

5. Exit the Sketcher Workbench, return to the Part Design Workbench

6. Click Pad and give the thickness for the part

7. Similarly select another plane or define a new plane using plane tool that is

offset with XY, YZ, and ZX plane

8. Enter Sketcher to define the sketch and give the required padding.

9. Make similar sketches followed by pocket command to cut the slots

10. Capture the image of the part so obtained

Result:

36

JOINTS 2

Cotter and Sleeve Joint

37

Experiment 9 JOINTS 2

Date:

Aim:

To draft the given 2D drawing of Joints into 3D using CATIA V5.20 software

Procedure:

1. Select the XY plane

2. Enter the Sketcher Workbench

3. Sketch the profile of the part without considering the dimensions

4. Constrain the profile to match the dimensions as given

5. Exit the Sketcher Workbench, return to the Part Design Workbench

6. Click Pad and give the thickness for the part

7. Similarly select another plane or define a new plane using plane tool that is

offset with XY, YZ, and ZX plane

8. Enter Sketcher to define the sketch and give the required padding.

9. Make similar sketches followed by pocket command to cut the slots

10. Capture the image of the part so obtained

Result:

38

ENGINE PARTS 1

Piston

Connecting Rod

39

Experiment 10 ENGINE PARTS 1

Date:

Aim:

To draft the given 2D drawing of Engine parts into 3D using CATIA V5.20 software

Procedure:

1. Select the XY plane

2. Enter the Sketcher Workbench

3. Sketch the profile of the part without considering the dimensions

4. Constrain the profile to match the dimensions as given

5. Exit the Sketcher Workbench, return to the Part Design Workbench

6. Click Pad and give the thickness for the part

7. Similarly select another plane or define a new plane using plane tool that is

offset with XY, YZ, and ZX plane

8. Enter Sketcher to define the sketch and give the required padding.

9. Make similar sketches followed by pocket command to cut the slots

10. Capture the image of the part so obtained

Result:

40

ENGINE PARTS 2

Stuffing Box

Crosshead

41

Experiment 11 ENGINE PARTS 2

Date:

Aim:

To draft the given 2D drawing of Engine parts into 3D using CATIA V5.20 software

Procedure:

1. Select the XY plane

2. Enter the Sketcher Workbench

3. Sketch the profile of the part without considering the dimensions

4. Constrain the profile to match the dimensions as given

5. Exit the Sketcher Workbench, return to the Part Design Workbench

6. Click Pad and give the thickness for the part

7. Similarly select another plane or define a new plane using plane tool that is

offset with XY, YZ, and ZX plane

8. Enter Sketcher to define the sketch and give the required padding.

9. Make similar sketches followed by pocket command to cut the slots

10. Open the CATIA assembly design and add the part design files to it

11. Add suitable constraints between the parts to have the assembly

12. Capture the rendering of the assembly so obtained

Result:

42

MACHINE COMPONENTS 1

Screw jack

43

Experiment 12 MACHINE COMPONENTS 1

Date:

Aim:

To draft the given 2D drawing of Machine components into 3D using CATIA V5.20

software

Procedure:

1. Select the XY plane

2. Enter the Sketcher Workbench

3. Sketch the profile of the part without considering the dimensions

4. Constrain the profile to match the dimensions as given

5. Exit the Sketcher Workbench, return to the Part Design Workbench

6. Click Pad and give the thickness for the part

7. Similarly select another plane or define a new plane using plane tool that is

offset with XY, YZ, and ZX plane

8. Enter Sketcher to define the sketch and give the required padding.

9. Make similar sketches followed by pocket command to cut the slots

10. Open the CATIA assembly design and add the part design files to it

11. Add suitable constraints between the parts to have the assembly

12. Capture the rendering of the assembly so obtained

Result:

44

MACHINE COMPONENTS 2

Tail Stock

45

Experiment 13 MACHINE COMPONENTS 2

Date:

Aim:

To draft the given 2D drawing of Machine components into 3D using CATIA V5.20

software

Procedure:

1. Select the XY plane

2. Enter the Sketcher Workbench

3. Sketch the profile of the part without considering the dimensions

4. Constrain the profile to match the dimensions as given

5. Exit the Sketcher Workbench, return to the Part Design Workbench

6. Click Pad and give the thickness for the part

7. Similarly select another plane or define a new plane using plane tool that is

offset with XY, YZ, and ZX plane

8. Enter Sketcher to define the sketch and give the required padding.

9. Make similar sketches followed by pocket command to cut the slots

10. Open the CATIA assembly design and add the part design files to it

11. Add suitable constraints between the parts to have the assembly

12. Capture the rendering of the assembly so obtained

Result:

46

MACHINE COMPONENTS 3

Machine vice

47

Experiment 14 MACHINE COMPONENTS 3

Date:

Aim:

To draft the given 2D drawing of Machine components into 3D using CATIA V5.20

software

Procedure:

1. Select the XY plane

2. Enter the Sketcher Workbench

3. Sketch the profile of the part without considering the dimensions

4. Constrain the profile to match the dimensions as given

5. Exit the Sketcher Workbench, return to the Part Design Workbench

6. Click Pad and give the thickness for the part

7. Similarly select another plane or define a new plane using plane tool that is

offset with XY, YZ, and ZX plane

8. Enter Sketcher to define the sketch and give the required padding.

9. Make similar sketches followed by pocket command to cut the slots

10. Open the CATIA assembly design and add the part design files to it

11. Add suitable constraints between the parts to have the assembly

12. Capture the rendering of the assembly so obtained

Result:

48

VIVA VOCE QUESTIONS

1. What is meant by tolerance? How many types of tolerance are there?

Tolerance is the difference between maximum and minimum dimensions of a

component, Depending on the type of application, the permissible variation of

dimension is set as per available standard grades. Tolerance is of two types,

bilateral and unilateral. When tolerance is present on both sides of nominal size, it

is termed as bilateral; unilateral has tolerance only on one side.

2. What are the types fit? Describe the differences.

The nature of assembly of two mating parts is defined by three types of fit system,

Clearance Fit, Transition Fit and Interference Fit.

Clearance Fit: In this type of fit, the shaft of largest possible diameter can be fitted

easily in the hole of smallest possible diameter.

Interference Fit: In this type of fit, irrespective of tolerance grade there is always a

overlapping of the matting parts.

Transition Fit: In this case, a clearance is present between the minimum dimension

of the shaft and the minimum dimension of the hole. However, the fit is tight, if

the shaft dimension is maximum and the hole dimension is minimum. Hence,

transition fit have both the characteristics of clearance fit and interference fit.

3. Define machine design.

A machine is a combination of several machine elements arranged to work

together as a whole to accomplish specific purposes. Machine design involves

designing the elements and arranging them optimally to obtain some useful work.

4. Expand CATIAV5.

Computer Aided Three Dimensional Interactive Application.

5. Is It Possible to directly enter in to Sketcher Workbench?

No, it is not possible to enter in to sketcher workbench directly. We have to go for

any workbench & form there we can enter the sketcher workbench.

6. What is use of construction elements?

Construction elements assist in sketching the required profile in sketcher.

7. What are the default units of LMT (Length, Mass and Time)

mm, Kg, Second.

49

8. What is SKETCH TOOLS in sketcher work bench & Explain the Importance of it?

SKETCH TOOLS in sketcher workbench are the commands, which find very use

in creating sketches. SKETCH TOOLS are namely geometric and dimensional

constraints, construction elements/standard elements and Grid option. They play

very important role in sketching, whenever we want to constrain a sketch we use

these options and if we want to convert any element into a construction element

once again these options come into picture.

9. What is the use of Cut Part by Sketch Plane?

This task shows how to make some edges visible. In other words, we are going to

simplify the sketch plane by hiding the portion of the material that is not needed

for sketching.

10. How do you measure arc length?

We can measure arc length by using MEASURE ITEM command. Sometimes we

need to customize the option for arc length if it is not checked earlier using

customization in MEASURE ITEM command.

11. What do you mean by ISO-Constraints?

If all of the degrees of freedom of geometry have been takes up by a consistent

combination of dimensions & fixed geometry,. That geometry is said to be ISO-

CONSTRAINED. Geometry that still has some degrees of freedom is said to be

UNDER constrained.

12. How many dimensions are required to constrain the ellipse?

Three dimensions are required namely major axis, minor axis and the distance

from the origin.

13. How many types of Co-ordinate systems are there?

Three namely Cartesian, Polar and Spherical co-ordinate system

14. Where do we use axis?

Axis is used in creating shaft (revolved) feature.

15. How many axis can be created in a single sketch?

Only one axis can be created in a sketch, if more than one axis are drawn then only

one of them, the latest one, will be axis and others will be converted into reference

elements.

50

16. What is kernel?

The kernel is the basic indispensable part of an operating system that allocates

resources such as low-level hardware interfaces & security.

17. What is the kernel of CATIA?

CNEXT

18. How many degrees of freedom are there for points, lines, circles & ellipse in 2

dimensions?

Degree of freedom for points & ellipse is 2 for circles it is 3 & for ellipse it is 5 in

two dimensions.

19. Expand CAD/CAM/CAE/PDM/VPM/CFD

Computer Aided (Design/Manufacturing/Engineering). Product Life cycle

Management/ Product Data Management/ Virtual Product Module/ Virtual Product

data management/ Computational Fluid Dynamics

20. Is it Possible to create pocket or groove as first features?

Yes, it is possible.(body concept)

21. How to give tolerance to particular dimension?

First, give the dimension & using right click select ADD TOLERANCE from the

contextual menu & specify the tolerance.

22. What is IUA? What is its purpose?

IUA= Interactive User Application Its purpose is to customize the CATIA user

command.

23. What is 'KEEP SPECIFICATION' in pattern?

By checking this option we can have instances same as that of the original & any

change made in the original will be observed in the instances.

24. What is use the of MERGE END option?

MERGE END' option when checked, will limit the extrusion to the exiting

material.

25. What is the difference between UFC and Power copy?

When we creating both its same but when you insert a UFC you will get only

feature and its parameters you can edit the parameters. when you inserting power

copy you will get both Feature and Sketch both.