0% found this document useful (0 votes)

2K views1 pageAerial Lift Inspection Checklist

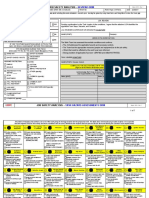

This document is an aerial lift daily inspection checklist. It contains 30 items that must be checked daily prior to using an aerial lift, including checking that the operator and occupants are trained, the work area is safe, lift components like fluids and lights are functioning properly, and personal protective equipment is available. Any issues found during inspection should be listed in the correction column. The completed form should be retained for one year for review by Facilities Management - Occupational Health and Safety.

Uploaded by

Dipak Kumar PatelCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

2K views1 pageAerial Lift Inspection Checklist

This document is an aerial lift daily inspection checklist. It contains 30 items that must be checked daily prior to using an aerial lift, including checking that the operator and occupants are trained, the work area is safe, lift components like fluids and lights are functioning properly, and personal protective equipment is available. Any issues found during inspection should be listed in the correction column. The completed form should be retained for one year for review by Facilities Management - Occupational Health and Safety.

Uploaded by

Dipak Kumar PatelCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd