Technical Dictionary PDF

Uploaded by

ApeuDerropTechnical Dictionary PDF

Uploaded by

ApeuDerropSSB_W001-W044_GB.

qxd

28.10.2003

8:56 Uhr

Seite W.1

General data

Certificates

W.2 - W.3

Electrical data

Rating the clearance and creepage distances

Current load curve

W.4 - W.6

W.7

General technical data

General information about CE marking

EMV directives

Protection types

Converting AWG conductors to mm2

Gauge pin

W.8

W.8 - W.9

W.10

W.11

W.11

Materials

Insulation materials

Metals

Current loading curves

W.12 - W.13

W.14

W.15

Technical dictionary

General data

Technical dictionary

Connection types

W.16 - W.17

ATEX

W.18 - W.19

Specific data

Terminals

Regulations / definitions

Assembling terminal strips

Connecting terminals

Use of aluminium conductors

Definition of the various types

Ex terminals ATEX

W.20

W.21

W.22

W.23

W.24 - W.25

W.26 - W.29

Relay couplers

W.30 - W.31

Opto-couplers

W.32 - W.34

Overvoltage protection

W.35 - W.41

Tools

Cutting

Stripping

Crimping

W.42

W.43

W.44

W

W.1

28.10.2003

Technical Dictionary

General

SSB_W001-W044_GB.qxd

W

W.2

US

8:57 Uhr

Seite W.2

28.10.2003

8:57 Uhr

Seite W.3

Technical Dictionary

General Data

Weidmller quality and

environmental management

for the benefit of our

customers

Product certificates create trust

Certification documents verify the quality

of our products. They are issued following

suitable tests by independent institutes

and are the prerequisite for use in certain

markets or fields of application.

The accredited test laboratory has its

expertise endorsed

The reliability of technical data is of great

importance for the user. In confirming the

accredited status, officially approved

authorities have certified the organisation

in accordance with EN 45 001 as well as

its expertise in defined assessment of

terminals, plug-in connectors, relays and

electronic equipment.

Certification as documentation of

managed quality

Quality management in the Weidmller

companies is based on ISO 9000 ff.

The corresponding certificates from

acknowledged, accredited authorities also

simplify your supplier appraisal procedures.

Verification of Weidmllers quality

also includes contracts with

independent institutions covering the

regular monitoring of production

facilities, quality management and the

laboratory.

Excellent environmental management

testifies to our total commitment. W.3

Allgemeines

SSB_W001-W044_GB.qxd

SSB_W001-W044_GB.qxd

28.10.2003

8:57 Uhr

Seite W.4

Technical dictionary

General data

Electrical data

Rating the clearance and creepage distances of electrical equipment

General information

Since April 1997, clearance and creepage

distances have been rated according to

the regulations of DIN VDE 0110-1,

Insulation coordination for equipment in

low voltage systems.

DIN VDE 0110-1 contains the modified

version of the IEC report 664-1 (see

IEC 664-1/10.92).

The latest catalogue gives the rating data

obtained for each product in compliance

with the provisions of this standard, where

applicable.

Clearance distances

Creepage distance

Clearance distances are rated in

accordance with the following factors:

Creepage distances are rated in

accordance with the following factors:

Anticipated overvoltage

Rated impuls voltage

Intended

Rated voltage

Used

Overvoltage protection precaution

Used insulation materials

Insulation materials group

Measures to prevent soiling

Degree of soiling

Measures to prevent soiling

Degree of soiling

Diagram showing clearance distance

Diagram showing creepage distance

For the rating of clearance and creepage

distances, application of the regulations

for insulation coordination produces the

following interrelationships:

Grooves are taken into account when

measuring creepage distances if their

minimum width X is rated according to

the following table:

Degree of

Minimum width

soiling

X in mm

1

0.25

1.0

1.5

2.5

If the corresponding clearance distance is

less than 3 mm, the smallest groove width

may be reduced to 1/3 of this clearance

distance.

W

W.4

SSB_W001-W044_GB.qxd

28.10.2003

8:57 Uhr

Seite W.5

Technical dictionary

General data

Electrical data

Rating the clearance and creepage distances of electrical equipment

Influential factors

Rated impulse voltage

Degrees of soiling

The rated impulse voltage is derived

from:

Degree of soiling 1

No or only dry non-conductive soiling.

Soiling has no influence.

Voltage conductor earth

(the rated voltage of the network, taking

into account all networks)

Degree of soiling 2

Only non-conductive soiling. Temporary

conductivity must be expected occasionally as a result of condensation.

Overvoltage category

Table 1: Rated impulse voltage for electrical equipment

Rated voltage of the power

supply system *) in V

Three-phase One-phase

systems

systems with

mid-point

120 to 240

Degree of soiling 3

Rated impulse voltage in kV for

Electrical equipment

at the power supply

of the installation

Electrical equipment

as part of the permanent installation

Electrical equipment Specially protected

for connection to the electrical equipment

perman. installation

(Overvoltage

category IV)

(Overvoltage

category III)

(Overvoltage

category II)

(Overvoltage

category I)

4.00

2.50

1.50

0.80

230/400

277/480

6.00

4.00

2.50

1.50

400/690

8.00

6.00

4.00

2.50

1000

Values for project planning in each individual case.

If no values are available, the values in the preceding line apply.

Conductive soiling occurs, or dry

non-conductive soiling which becomes

conductive because of condensation.

Degree of soiling 4

Soiling results in constant conductivity,

e.g. caused by conductive dust, rain

or snow.

*) acc. to IEC 38

Unless explicitly stated otherwise, the

dimensioning of clearance and creepage

distances, and hence the thus-derived

rating data for electromechanical products

(terminals, terminal strips, PCB connection

terminals and plug-in connectors) is based

on degree of soiling 3 and overvoltage

category III, taking account of all network

types.

Stipulating the overvoltage

categories

according to national standard DIN

VDE 0110-1 (for electrical equipment fed

directly from the low voltage network)

Overvoltage category I

Overvoltage category III

Devices for connection to the permanent electrical installation of a building.

Outside the device, measures have

been taken either in the permanent

installation, or between the permanent

installation and the device, to limit the

transient overvoltage to the relevant

value.

Devices which are an integral part of

the permanent installation, and other

devices expected to have a higher

degree of availability.

Overvoltage category II

Overvoltage category VI

Devices for connection to the

permanent electrical installation of a

building,

Devices for use at or near the power

supply in the electrical installation of

buildings, between the principal

distribution and the mains,

e.g. domestic appliances, portable

tools.

e.g. distribution boards, circuit

breakers, distribution devices (including

cables, busbars, distribution boxes,

switches, sockets) in the permanent

installation and devices for industrial

use, and other devices such as

stationary motors with continuous

connection to the permanent

installation.

e.g. electricity meters, overcurrent

protection switches and centralised

controllers.

W

W.5

SSB_W001-W044_GB.qxd

28.10.2003

8:57 Uhr

Seite W.6

Technical dictionary

General data

Electrical data

Rating the clearance and creepage distances of electrical equipment

Influence factors

Rated voltage

Insulation material group

The rated voltage is derived from the

rated voltage of the power supply and

the corresponding network type.

The insulation materials are divided into

four groups depending on the comparative

figures for creepage distance (CTI:

comparative tracking index):

Table 3a:

Single phase 3 or 2 conductor a.c. or d.c. networks

Rated voltage

of the power

supply system

(network)*)

Voltages for table 4

Voltages for table 4

for insulation confor insulation

ductor conductor 1) conductor earth 1)

all systems

Table 3b:

Three-phase 4 or 3 conductor a.c. networks

3-conductor

systems,

with mid-point

earthing

Rated voltage

of the power

supply system

(network) *)

for insulation

conductor

conductor

all systems

Insulation material group

for insulation

conductor earth

three-phase 4conductor systems with earthed neutral 2)

three-phase 3-conductor systems;

unearthed 1) or

earthed conductor

V

12.5

V

12.5

V

60

V

63

V

32

V

63

24 / 25

30

25

32

110/120/127

125

80

125

150**)

160

160

42 / 48 / 50**)

60

50

63

208

200

125

200

30-60

63

32

220/230/240

250

160

250

100**)

100

300**)

320

320

110 / 120

150**)

125

160

380/400/415

400

250

400

440

500

250

500

480/500

500

320

500

575

630

400

630

220

250

110-220

120-240

250

125

600**)

630

630

300**)

320

660/690

630

400

630

220-440

500

250

720/830

800

500

800

600**)

630

960

1000

630

1000

480-960

1000

500

1000**)

1000

1000

1000**)

1000

1) Conductor-earth insulation levels for unearthed or impedance earthed

systems are the same as those for conductor-conductor insulation

because, in practice, the operating voltage of every conductor to earth

can match the conductor-conductor voltage. This is because the actual

voltage to earth is defined by the insulation resistance and by the

capacitive blind resistance of every conductor to earth. This means that

a low (but tolerated) insulation resistance of a conductor can effectively

earth it and raise the other two to the value of the conductor-conductor

voltage against earth.

2) For electrical equipment intended both for use in three-phase 4-conductor and in three-phase 3-conductor systems, both earthed and

unearthed, only the values for the 3-conductor systems should be used.

*) It is presumed that the value of the rated voltage of the electrical

equipment is not below the value of the rated voltage of the power

supply system.

**) Following jointly undertaken alterations, the meaning of the **) marking

has not been adopted in Table 1. Its definition: the /- dash refers to a

three-phase 4-conductor system. The lower value is the voltage

external to neutral conductor, the higher value is the voltage external

to external conductor. If only one value is stated, it refers to three-phase

3-conductor systems and refers to the voltage external to external

conductor.

Tables 3a and 3b still refer to the values in Table 1 by using the **) marking.

W

W.6

600 CTI

II

400 CTI < 600

III a

175 CTI < 400

III b

100 CTI < 175

The comparative tracking index is required

to have been determined using special

samples produced for this purpose with

test solution A in compliance with IEC 60112

(DIN IEC 60112/DIN VDE 0303-1).

SSB_W001-W044_GB.qxd

28.10.2003

8:57 Uhr

Seite W.7

Electrical data

Basic curve

Technical dictionary

General data

Current load curve

(derating curve)

Current loading curve

Upper temperature limit

of the component

The derating curve shows which currents

can flow continuously and simultaneously

across all possible connections when the

component is exposed to various ambient

temperatures below its upper temperature

limit.

The upper temperature limit of a component is a rating value which depends on

the used materials. The sum of ambient

temperature and overtemperature produced by the current load (power loss at the

forward resistance) must not exceed the

upper temperature limit of the component,

so as not to damage or destroy it. The

current loading ability is therefore not a

constant value but falls with increasing

component ambient temperature. In addition, the power loading ability is influenced

by component geometry, number of pins

and connected conductor.

tg = upper temperature limit of component

tu = ambient temperature of component

ln = load current

tg =

tu =

ln =

a=

b=

The current loading ability is empirically

determined acc. to DIN IEC 60152-3.

In view of the fact that it is effectively not

possible to select components with maximum permissible forward resistances for

measurement purposes, the basic curve

has to be reduced. A reduction of the

loading currents to 80 % results in the

power loading curve. Here allowance

has to be made for the maximum tolerable

forward resistances and inaccuracies

incurred in measuring the temperatures,

so that these curves are adequate for

practical use as indicated by experience.

If, within the low ambient temperature

range, the current loading curve exceeds

the current permissible as based on the

current loading ability of the conductor

cross-sections requiring connection, then

the current loading curve is limited to the

smaller current for this temperature range.

For this purpose, the corresponding component temperatures tb1, tb2 and the ambient temperatures tu1, tu2 are measured

for three different loading currents l1, l2

The values are entered in a linear system

of coordinates (as shown in Fig. 1) to

illustrate the relationships between the

loading currents, the component ambient

temperature and the component overtemperature.

The Y-axis is used for the loading

currents and the X-axis for the ambient

temperatures. A perpendicular on the

X-axis at the component's upper temperature limit tg completes the coordinate

system

upper temperature limit of component

ambient temperature of component

load current

basic curve

reduced basic curve (current loading curve)

For every current l1, l2, .. the corresponding mean values for component overtemperatures t1 = tb1 tU1, t2 = tb2 tU2,

are entered starting from the perpendicular and working to the left.

The points found in this way are connected to form a parabolic curve.

W

W.7

SSB_W001-W044_GB.qxd

28.10.2003

8:57 Uhr

Seite W.8

Technical dictionary

General data

General technical data

General information about

CE marking

EMC directives

The CE mark on various products and

their packaging is neither a quality feature

nor an indication of quality or safety.

The CE mark is a control sign that was

created and brought into effect for open

trading within the European market.

It does not refer to the address of the end

consumer. The CE mark only confirms

that a manufacturer has complied with all

of the directives of the European Union

(EU) that are applicable to this product.

Therefore the CE mark is proof of

directive conformity and is directed

towards the responsible control

authorities.

The CE mark can be said to be the

passport for products that are to be

traded within Europe.

According to the low-voltage directive, a

conformity evaluation process must be performed on the product whereby

conformity to the directive is assumed where

a reference to the harmonised European

standards or to the other technical specifications, e.g. IEC standards or national standards, is made.

Electronic Products from Weidmller

Regarding EMC Guidelines

With the decree of the Directive of the

council dated 3rd. May 1989 for the

alignment of the legal requirements of the

member states concerning electromagnetic

compatibility (89/336/EEC), the European

Union (EU) has declared EMC as a

protection objective.

passive interface elements with and

without status displays

Weidmller considers all relevant EU

directives to the best of its knowledge.

The currently applicable directives are

as follows:

73/23/EEC

The protection objectives are defined in

article 4 of the EMC directive dated 19th.

November 1992, and state the following:

the generation of electromagnetic

interference must be so reduced so that

the intended operation of radio,

telecommunications and other devices is

possible.

Electrical equipment for use within

specific voltage ranges (Low voltage

directive)

the devices must have a suitable

resistance to electromagnetic interference

in order to ensure intended operation.

89/336/EEC

Devices are defined in the EMC

directive as:

Electromagnetic compatiblity

(EMC directive)

98/392/EEC

Safety of machines (Machinery directive)

all electrical and electronic equipment,

installations and systems that contain

electrical and electronic components

The standards mentioned in the directives

have been an element of Weidmller's

standard development for a considerable

time. This provides the guarantee of

conformity to the European directives.

Our testing laboratory, accredited

according to EN 45001, performs the

standard conform testing. The testing

reports are recognised within Europe

within the framework of the accreditation

process.

This applies to active/passive components

and intelligent modules that are produced

and stored by Weidmller.

73/23 EEC

Low-Voltage Directive (LVG)

industrial installations

Electrical equipment in the sense of this

directive are all electrical equipments that

are used with a nominal voltage between

50 and 1000 Vac and between 75 and

1500 Vdc.

If an electrical product has the CE mark,

it must fulfil the requirements of the EMC

directive and if necessary the low-voltage

directive (above 50 Vac and above 75 Vdc).

W

W.8

The adherence to this directive is assumed

for the devices that conform with the

harmonised European standards that, for

example, are released in the gazette from

the Federal Minister for Post and Telecommunications.

The devices are utilised in the following

areas:

medical and scientific equipment and

devices

Category 1

All passive components such as:

terminals with status displays

protection terminals with status displays

overvoltage protection

These products cause no interference and

they have a suitable immunity to interference. These products are not labelled with

the CE mark concerning the EMC directive

or the EMC guideline.

Category 2

These products are labelled with the CE

mark after the conformity evaluation

process has been performed which

contains the reference to the harmonised

European standards.

The following are harmonised standards:

EN 50081-1

Generic Emission Standard for

residential, commercial and light industrial

environments

EN 50082-1

Generic Immunity Standard for

residential, commercial and light industrial

environments companies

EN 50081-2

Generic Emission Standard for heavy

industrial environments

EN 50082-2

Generic Immunity Standard for heavy

industrial environments

EN 55011

Radio Interference for ISM Devices

EN 55022

Radio Interference for Information

Technology Facilities

information technology devices

EN 61000-3-2

Harmonics

Weidmller tests its electronic products

according to the relevant standards in order

to fulfil the agreed protection objectives.

EN 61000-3-3

Voltage Fluctuations

EN 6100 0-4-x

approx. 10 partial tests for interference

immunity; partly not ratified.

SSB_W001-W044_GB.qxd

28.10.2003

8:57 Uhr

Seite W.9

EMC directives

Usage of Tests

Criterion B

General Installation Instructions

Generic standards are always used

when device-specific product standards

do not exist. The generic standards of

EN 50081-2 and EN 50082-2 are used

as the basis for Weidmller products.

The equipment shall continue to operate

as intended after the test. No degradation

of performance or loss of function is

allowed below a minimum performance

level as specified by the manufacturer,

when the equipment is used as intended.

In agreement with the performance level

and the criteria A and B, the products are

allowed and can be affected externally

during the occurrence of a fault.

Remark:

The relevance of EN 50082-1 for certain

products must be checked as well as how

far EN 50081-1 or 50082-1 was considered during testing.

The environment phenomenon and test

interference levels are specified in the

generic immunity standard. Additionally,

Weidmller considers the evaluation

criteria A, B and C.

Text extract from the Generic Standard

EN 50082-2:

Criterion A

The equipment shall continue to operate

as intended. No degradation of

performance or loss of function is allowed

below a minimum performance level as

specified by the manufacturer, when the

equipment is used as intended.

In certain cases, the nominal performance

level can be replaced by an permissible

loss of performance.

If the minimal performance level or

permissible loss of performance is not

specified by the manufacturer, both of

these specifications can be extracted from

the description of the product, the relevant

documentation and from what the operator expects from the equipment during its

intended operation.

In certain cases, the minimal performance

level can be replaced by an permissible

loss of performance. During testing

degradation of the performance level is

permitted however changes to the

specified operation mode or data loss are

not permitted.

Technical dictionary

General data

General technical data

It should be attempted, as far as possible,

to prevent this with an optimal installation.

Measures:

installation of the products in an

enclosed metal box (control cabinet,

metal housing)

protect the voltage supply with an

If the minimal performance level or

overvoltage protection device.

permissible loss of performance is not

(For mains supply of 230/400 Vac with

specified by the manufacturer, both of

a PU type and for 24 Vdc with an EGU

these specifications can be extracted from

or LPU.)

the description of the product, the relevant

documentation and from what the opera- only use shielded cables for analogue

tor expects from the equipment during its

data signals

intended operation.

follow ESD measures during installation,

maintenance and operation

Criterion C

A temporary loss of function is permitted,

provided the loss of function is self

recoverable or can be restored by the

operation of the controls.

Criterion B is most frequently specified in

the generic standards and is used by

Weidmller.

An example of an analogue coupler EMA:

During testing, the analogue coupler can

convert values that are outside the

permissible tolerances.

After testing however, the values must be

within the available tolerances.

distance between electronic modules

and interference sources (e.g. invertors)

and power lines should be at least

200 mm.

maintenance of ambient temperature

and relative humidity

long cables are to be protected by overvoltage protection devices.

For safety reasons, the operation of

walkie-talkies and mobile telephones

should only be performed outside a

radius of 2 m.

W

W.9

SSB_W001-W044_GB.qxd

28.10.2003

8:57 Uhr

Seite W.10

Technical dictionary

General data

General technical data

Protection rating according to EN 60 529 / DIN 0470

The protection ratings are indicated by a code consisting of

the two invariable letters IP and two digits representing

the degree of protection.

Example:

I P 6 5

2nd digit: protection from water

1st digit: protection from solid bodies

Degrees of protection from water

(2 nd digit)

Degrees of protection from solid foreign

bodies (1st digit)

Number

Number

Not protected

Not protected

Protected from solid foreign bodies 50 mm in diameter and above. Protection to prevent dangerous

parts being touched with the back of the hand.

Vertically falling drops must not have any

harmful effect.

Protected from solid foreign bodies 12.5 mm in diameter and above. Protection to prevent dangerous

parts being touched with the fingers (finger-safe).

Vertically falling drops must not have any

harmful effect if the housing is inclined at an

angle of up to 15 to the vertical on both sides.

Protected from solid bodies 2.5 mm in diameter

and above. Protection to prevent dangerous parts

being touched with a tool.

Water sprayed at an angle of up to 60 to the

vertical on both sides must not have a harmful

effect.

Protected from solid bodies 1 mm in diameter and

larger. Protection to prevent dangerous parts being

touched with a piece of wire.

Water splashing against the housing from any

direction must not have a harmful effect.

Dust protected. Penetration of dust is not completely prevented, but dust must not penetrate in

quantities that would impair satisfactory working

of the device or safety.

Water sprayed against the housing from any

direction must not have a harmful effect.

Dust-proof, no penetration by dust.

Water aimed in a strong jet against the housing

from any direction must not have a harmful effect.

Water must not penetrate in any quantity which

causes harmful effects if the housing is temporarily

submerged in water under standard pressure and

time conditions.

Water must not penetrate in any quantity which

causes harmful effects if the housing is permanently

submerged in water under conditions which must

be agreed between manufacturer and user.

However, the conditions must be more adverse

than under number 7.

W

W.10

SSB_W001-W044_GB.qxd

28.10.2003

8:57 Uhr

Seite W.11

Converting AWG conductors to mm2

Gauge pin acc. to IEC 60947-1 section 8.2.4.5.2 table 7

AWG is the abbreviation for American

Wire Gauge. This gives no indication of

the actual conductor cross-sectional area.

Possibility of inserting unprepared

round conductors with the largest

stipulated cross-sectional area

The relationship between AWG and mm2

is shown in the following table.

Testing with stipulated gauge, inserted

under own weight.

AWG

mm

28

26

24

22

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

0.08

0.13

0.21

0.22

0.52

0.65

0.82

1.04

1.31

1.65

2.08

2.63

3.31

4.17

5.26

6.63

8.37

10.55

13.30

16.77

21.15

26.67

33.63

42.41

53.48

Conductor crosssectional area

Rigid conductor

(single- or multicore) mm2

1.5

2.5

4

6

10

16

25

35

50

70

95

120

150

Technical dictionary

General data

General technical data

Pin

Form A

Form B

Designation

Diameter

a

mm

Width

b

mm

Designation

Diameter

a

mm

A1

A2

A3

A4

A5

A6

A7

A8

A9

A 10

A 11

A 12

A 13

2.4

2.8

2.8

3.6

4.3

5.4

7.1

8.3

10.2

12.3

14.2

16.2

18.2

1.5

2.0

2.4

3.1

4.0

5.1

6.3

7.8

9.2

11.0

13.1

15.1

17.0

B1

B2

B3

B4

B5

B6

B7

B8

B9

B 10

B 11

B 12

B 13

1.9

2.4

2.7

3.5

4.4

5.3

6.9

8.2

10.0

12.0

14.0

16.0

18.0

Tolerable

deviations for a

and b mm

0 0.05

0 0.06

0 0.07

0 0.08

W

W.11

SSB_W001-W044_GB.qxd

28.10.2003

8:57 Uhr

Seite W.12

Technical dictionary

General data

Materials

Insulation materials

In order to satisfy all the different requirements

made of our products, we have to use various

insulation materials tailor-made to each specific

application.

All insulation materials used by Weidmller are free

from harmful substances. It is especially important

that these materials contain no cadmium. In

addition, they are free from heavy metal colour

pigments, dioxin and furan-forming substances.

Thermosetting plastics

Plastic

Abbreviation

Germin

KrG

Stamin

KrS

Epoxy resin

EP

Thermosetting plastics have outstanding dimensional stability, low water absorption, excellent

creepage current resistance and outstanding fire resistance.

Their continuous service temperature is higher than that of thermoplastics. Under high thermal

load, thermosetting plastics have better dimensional strength than thermoplastics.

Thermosetting plastics are, however, inferior to thermoplastics in terms of their flexibility.

Melamine resin

pressing compound

MF type 150

(DIN EN ISO 14 528)

Organic filler

Melamine resin pressing

compound

MF type 156

(DIN EN ISO 14 528)

Inorganic filler

Epoxy resin

with

inorganic filler

mid-yellow

anthracite

black

high continuous service

temperature

continuous service

temperature higher

(than Germin)

very good electrical

properties

Colour

Description

high fire resistance

high creepage current

resistance

inherent flammability

protection

high fire resistance

very high continuous service

temperature

high creepage current

resistance

resistant to high-energy

radiation

inherent flammability

protection

halogen- and phosphorousfree; flame retardant

108

1014

Properties

Specific forward resistance acc. to IEC 93

Dielectric strength acc. to IEC 243-1

Creepage current resistance (A) to IEC112

1011

10

12.5

160

600

600

600

Upper max. tol. limit temperature

130

140

160

Lower max. tol. limit temperature, static

60

60

60

V-0 (5 V-A)

V-0 (5 V-A)

V-0

Combustibility acc. to UL 94

Fire behaviour acc. to railways standard

W

W.12

SSB_W001-W044_GB.qxd

28.10.2003

8:57 Uhr

Seite W.13

Technical dictionary

General data

Materials

Thermoplastics

Wemid

Wemid is a modified

thermoplastic whose

properties are especially

tailored to make it suitable for

use in our power connectors.

Advantages over PA include

enhanced fire protection and

higher continuous service

temperature. Wemid fulfils the

strict requirements for use in

railway vehicles according to

NF F 16-101.

Polyamide

PA

Polyamide (PA) is one of

the most frequently used

technical plastics. The

advantages of this material

includes its very good

electrical and mechanical

properties, flexibility and

resistance to breakage.

In addition, its chemical

structure gives PA good fire

resistance even without the

use of flame retardants.

Polyamide

PG GF

Glass-fibre reinforced

polyamide (PG GF)

offers excellent dimensional

stability and very good

mechanical properties.

This makes it ideal for use as

end bracket.

Unlike PA, this material in

unreinforced state comes

under combustibility class HB

in accordance with UL 94.

Polybutylene

terephthalate PBT

Polycarbonate

PC

Thermoplastic polyester

(PBT)

offers excellent dimensional

stability (which is why it is

used for plug-in connectors)

and high continuous service

temperature. It has lower

creepage current resistance

than other insulation

materials.

special Weidmller

insulating material

insulating material

insulating material

with or without

glass-fibre reinforcement,

depending on use

with or without

glass-fibre reinforcement,

depending on use

dark beige

beige

dark beige

orange

grey

higher continuous

service temperature

flexible, resistant

to breakage

excellent dimensional

stability

high dimensional

stability

high dimensional

stability

enhanced fire resistance

good electrical and

mechanical properties

very good mechanical

properties

good electrical and

mechanical properties

high continuous service

temperature

flame retardant, without

dioxin and furan-forming

substances

high electrical insulating

power

1013

1016

halogen- and phosphorousfree; flame retardant

self-extinguishing properties

low smoke

permitted for use in railways

acc. to NF F 16-101

1012

1012

1012

halogen-free;

flame retardant

25

30

30

28

30

600

600

500

200

175

120

100

120

115 / 130

115 / 125

50

50

50

50

50

V-0

V-2

HB

V-0

V-2 / V-0

I2 / F2 *)

I2 / F2

W

*) also qualified acc. to

LUL E 1042

W.13

SSB_W001-W044_GB.qxd

28.10.2003

8:57 Uhr

Seite W.14

Technical dictionary

General data

Materials

Metals

Weidmller uses only tried and tested

materials for the electrical components in

its products.

All materials are subjected to rigorous

quality monitoring under a quality

management system certified to

DIN EN ISO 9001.

Environmental compatibility plays a crucial

role in the selection of materials.

All metals used by Weidmller are

selected, processed and surface-treated

according to the very latest technical

findings.

Steels

Conductive materials

Steel parts whose function is to

permanently maintain contact force are

zinc electroplated, with an additional

chromate layer added to provide

additional passivation.

The current-carrying materials copper,

brass and bronze are characterised by

both high conductivity and good

mechanical properties.

Surface protection complies with the very

highest standards. Results from laboratory

tests are incorporated in producing the

surface finish.

Zinc still offers corrosion protection over a

longer period of time even if the zinc

coating is partially damaged by scratches

or pores.

Zinc acquires a negative charge in relation

to steel under the influence of an

electrolytic fluid. The metal ions in the zinc

migrate to the steel giving the base

material lasting protection against

corrosive attack.

W

W.14

The surfaces are usually finished with tin

plating. This guarantees that the contact

has outstanding adaptive properties with

low transition resistance. The tin plating

not only gives consistently good electrical

properties but also affords excellent

protection from corrosion.

Soldered connections are also provided

with tin plating. To safeguard soldering

ability over longer periods of time (storage

periods), brass parts are also given an

additional nickel layer to serve as a

diffusion barrier.

The nickel layer is highly effective in

preventing zinc atoms from diffusing

out of the brass.

SSB_W001-W044_GB.qxd

28.10.2003

8:57 Uhr

Seite W.15

Materials

The maximum current which a terminal

can carry depends on:

Technical dictionary

General data

Current loading curves

Current loading curve

for upper continuous service temperature 100C polyamide 66

35

the inherent temperature rise of the

terminal

30

the ambient temperature

An upper service temperature has been

defined for every Weidmller terminal, and

this must not be exceeded in continuous

operation.

25

Loading current [A]

the cross-sectional area of the

connected conductor

10

0

0

10

20

30

40

60

70

80

90

100

110

120

130

140

100

110

120

130

140

100

110

120

130

140

Current loading curve

for upper continuous service temperature 120C Wemid

35

30

25

20

15

10

5

Thermoplastic (polyamide 66)

WEMID

10

20

30

40

50

60

70

80

90

Ambient temperature T [C]

Duroplastic (MF 150 KrG)

Current loading curve

for upper continuous service temperature 130C MF 150 KrG

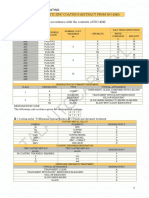

Depending on the insulation material

used, the rating current can be conducted

up to an ambient temperature of 55 C for

PA 66, 75 C for Weidmllers insulation

material WEMID, or up to 85 C for

duroplastic insulation materials (KrG).

35

30

25

Loading current [A]

Above these temperature limits, the

current is to be reduced in accordance

with the current expectancy curves.

50

Ambient temperature T [C]

Loading current [A]

Figs. 13 show examples of current

heating curves (in this case for a rated

current of 32 A) for three different

insulating materials:

15

The continuous service temperature

depends on the insulation material used in

the terminal. According to EN 60 947-7-1,

a terminal may not heat up by more than

45 K.

When the input current is at least

equivalent to the rated current, the

maximum ambient temperature to which

a terminal may be subjected is equal to

the continuous service temperature for

the insulation material used, less the

maximum tolerable temperature rise of

the terminal acc. to EN 60 947-7-1.

20

20

15

10

5

0

0

10

20

30

40

50

60

70

80

90

Ambient temperature T [C]

W

W.15

SSB_W001-W044_GB.qxd

28.10.2003

8:57 Uhr

Seite W.16

Technical dictionary

General data

Connection types

Clamping yoke connection

Pressure clamp connection

Weidmllers tension clamp system

optically combines the specific properties

of steel and copper. The system has

proven its worth billions of times over in

various Weidmller products. Both the

tension clamp and the clamping screw

consist of hardened steel. This clamping

yoke unit generates the necessary contact

force. Connection of the conductor

involves the tension clamp pressing the

conductor against the busbar, which is

made of copper or

high-quality brass. Weidmllers tension

clamp produces a gas-tight, vibrationresistant connection between the conductor and the busbar.

With its patented pressure clamp connection, Weidmller has developed a

screw connection system for conductors

with large cross-sectional areas. The

screw unit can be taken right out of the

terminal, making it easier to insert larger

conductors (which often otherwise proves

difficult). The conductor is placed directly

on the busbar, the screw unit replaced

and the conductor clamped in position.

Weidmllers TOP connection system

fulfils the requirement that conductor

insertion and screw actuation take place

in parallel. This brings wiring advantages

in certain installation situations, for

example with close lateral spacing in

installation boxes. The TOP connection

system combines the special properties of

steel and copper. The hardened steel

pressure clamp presses the conductor

directly against the copper or brass

busbar. The high contact force guarantees

a gas-tight connection between

conductor and busbar.

Vibration resistance

The force generated by turning the

clamping screw means that the upper

thread overlap springs back and exerts

a counter-effect on the screw.

Vibration resistance

The difference in length d between the

shank of the clamping screw and the

resilient pressure clamp means that the

pressure clamp undergoes elastic

deformation when the screw is tightened.

The high spring force of the pressure

clamp gives rise to vibration resistance

and at the same time counteracts the

tendency for the connected conductor to

settle. It is not, therefore, necessary to

tighten the clamping screw.

Vibration resistance

The force exerted by the steel pressure

clamp when the screw is tightened pulls

the two halves of the TOP connection

thread apart, as in the tension clamp.

This exerts a braking effect on the screw

and guarantees outstanding vibration

resistance.

Weidmllers tension clamp system is

vibration-resistant.

Any settling of the connected conductor

is counteracted by the elastic behaviour of

Weidmllers tension clamp. This means it

is not necessary to tighten the clamping

screw.

W.16

TOP connection

SSB_W001-W044_GB.qxd

28.10.2003

8:57 Uhr

Seite W.17

Connection types

IDC technology

Direct push in technology

Weidmllers tension clamp system

functions in similar fashion to the tried and

tested clamping yoke. As with the latter,

the tension clamp preserves the

separation of mechanical and electrical

functions. The tension clamp of highquality rust- and acid-resistant steel pulls

the conductor against the galvanised

copper busbar. The surface-treated

busbar has low contact resistance and is

highly resistant to corrosion. These

properties are preserved by the balancing

effect of the tension clamp.

IDC (insulation displacement

connection) technology is a means of

connecting copper conductors which

involves absolutely no preparation of the

conductor in other words, no stripping

and no crimping.

Direct push in technology involves the

stripped solid conductor simply being

pushed into the terminal as far as it will go

thats all there is to it. No tools are

required, and a reliable, vibration-resistant

and gas-tight connection is produced.

Even flexible conductors with crimped wire

end ferrules or ultrasonic welded

conductors can be connected without any

problems.

When the conductor is connected, its

insulation is penetrated and, at the same

time, the electrical contact is produced

between the conductor and the busbar.

As with the other types of connection,

Weidmllers IDC principle ensures

separation of mechanical and electrical

functions.

A stainless steel spring presses the busbar

against the conductor, thus guaranteeing

low contact resistance and a gas-tight,

vibration-resistant connection.

Technical dictionary

General data

Tension clamp connection

A stainless steel spring, held in a separate

cage, guarantees that the conductor

exerts a strong contact force on the

busbar (copper- and tin coated). The

conductor pull-out forces are even higher

here than in the tension spring system.

In the steel cage, a spring and a

conductor stopper guarantee optimum

conditions for connection and guide the

screwdriver for the purpose of releasing

the conductor.

W

W.17

SSB_W001-W044_GB.qxd

28.10.2003

8:57 Uhr

Seite W.18

Technical dictionary

General data

ATEX

ATEX 95 (formerly ATEX 100a)

Protection class

The former directive for Ex protection

Protection

Code

issued by the European Council under

76/117 EEC became invalid with effect

Gen. requirements

from 1 July 2003. Now only directive

Oil encapsulation

o

94/9/EEC or ATEX 95 applies (ATEX:

Overpressure encapsulation

p

Atmosphre Explosive); this is one of the

Sand encapsulation

q

so-called new approach directives.

Pressure-resistant encapsulation

d

It applies in all countries of the European

Increased safety

e

Union together with Iceland, Liechtenstein

Inherent safety

ia

and Norway.

Inherent safety

ib

In these countries it refers to the sale and

Type n (EEx n)

n

commissioning of products which have

Sealing encapsulation

m

been specially developed for areas in

which the presence of gases, vapours, fog

or dust give rise to a potentially explosive

atmosphere. It now also covers the mining Classification for explosion-risk areas

industry and purely mechanical devices.

CENELEC

Presence of a potentially

The ATEX directive has been in force since

March 1996. It was valid on an optional

basis through to 30 June 2003 (interim

period) in parallel to the existing directives.

As of this date, all new systems and devices for installation in explosion-risk areas

must conform with the ATEX directive and

be certified accordingly. The former categorisation into zones (zone 0, 1 or 2) and

protection classes (e.g. i: inherent safety,

e enhanced safety) still apply.

classification

IEC60079-10

explosive atmosphere

Zone 0

Zone 20

Zone 1

Zone 20

Zone 2

Zone 22

constant, long-term

or frequent

occasional

rare and

short-term

CENELEC

EN

IEC

50014

50015

50016

50017

50018

50019

50020

50020

50021

50028

60079-0

60079-6

60079-2

60079-5

60079-1

60079-7

60079-11

60079-11

60079-15

60079-18

Device category

explosion-protected

2

2

2

2

2

1

2

3

2

Device

category

US ClassifiFlammable

cation NEC 500 media

1G

1D

2G

2D

3G

3D

Class I, Div 1

Class II, Div 1

Class I, Div 1

Class II, Div 1

Class I, Div 2

Class II, Div 2

Gases, vapours

Dust

Gases, vapours

Dust

Gases, vapours

Dust

Explosion groups

Gas (e.g.)

CENELEX

NEC 500

Propane

Ethylene

Hydrogen

Acetylene

Methane (mining)

IIA

IIB

IIC

IIC

I

D

C

B

A

Mining (MSHA)

Max. surface

temperature (C)

Temperature class

CENELEC

Temperature class

NEC 500-3

450

300

280

260

230

215

200

180

165

160

135

120

100

85

T1

T2

T3

T4

T5

T6

T1

T2

T2A

T2B

T2C

T2D

T3

T3A

T3B

T3C

T4

T4A

T5

T6

Temperature classes

W

W.18

SSB_W001-W044_GB.qxd

28.10.2003

8:57 Uhr

Seite W.19

ATEX

Technical dictionary

General data

ATEX 95 (formerly ATEX 100a)

Marking example

Terminal WDK 4 N V

Rated conductor cross-sectional area

Rated voltage

Device group II - above ground

(gases, vapours, fog, dust)

CENELEX protection class

e enhanced safety

Device category 2

use in zone 1 or 21

Device group II

above ground

(gases, vapours,

fog, dust)

Approved for use in gases

G and/or dust D

European symbol for

explosion protection

Approval number

Example of marking

Assembled enclosure

for enhanced safety

CENELEC ignition protection

e enhanced safety

Approved for use

in gases G

Device category 2

Use in zone 1

Device group II above ground

(gases, vapours, fog, dust)

Temperature class T6

Max. surface temperature without

dust ignition 100C

Enclosure protection > IP64

Approval number

Device category 2

use in zone 21

Approved for use

in dust D

Rated voltage

Rated conductor

cross-sectional area

W

W.19

SSB_W001-W044_GB.qxd

28.10.2003

8:57 Uhr

Seite W.20

Technical dictionary

General data

Terminals

Regulations / definitions

Terminals acc. to VDE 0611-1

This standard was published in Germany

in August 1992:

VDE 0611-1 Low-voltage switchgear

part 7: Ancillary equipment section 1

Terminal blocks for copper conductors.

The contents of this standard correspond

to the international standard:

IEC 60947-7-1:

1989 Low voltage switchgear and control

gear part 7: Ancillary equipment section 1

Terminal blocks for copper conductors

At the European level this standard has

been ratified by CENELEC, making it valid

in the following countries:

Austria, Belgium, Denmark, Finland,

France, Germany, Greece, Holland, Iceland, Ireland, Italy, Luxembourg, Norway,

Portugal, Spain, Sweden, Switzerland,

United Kingdom

Combined application in order of priority:

IEC 60947-1

Low-voltage switchgear and control gear

part 1: General Rules

EN 60947-1

VDE 0660 part 100

Low-voltage switchgear part 1:

General Rule

Scope VDE 0611-1

(EN 60947-7-1)

(IEC 60947-7-1)

This standard stipulates the requirements

for terminals with screwed or screwless

terminal strips intended primarily for industrial or similar use, with the terminals

fastened to a carrier to produce both electrical and mechanical connections

between copper conductors. It applies

to terminals used for connecting round

copper conductors with a cross-section

between 0.2 mm2 and 300 mm2 (AWG

24/600 kcmil), and for electronic circuits

up to 1000 Vac 1000 Hz or up to 1500

Vdc.

Remarks:

This standard is also used as guide for

special kinds of terminals (e.g. isolating

terminals) for which no special standards

are available.

W

W.20

CE mark

Terminals/

feed-through terminals

Rated surge voltage

DIN VDE 0110-1 / VDE 0660 part 100

An insulating part which carries one or

several mutually insulated terminal arrays

intended for fastening to a carrier.

Peak values of a surge voltage which can

be applied to the terminals and to which

the clearance distances acc. to VDE 0660

part 100 or DIN VDE 0110-1 refer.

Rated cross-section

The rated cross-section of a terminal is

the cross-section of the conductor to be

connected by the terminal as stated by

the manufacturer. It is determined by certain thermal, mechanical and electrical

requirements, and is one of the specifications marked on the terminal.

The rated cross-section is selected from

the following standard cross-sections:

0.2 0.5 0.75 1 1.5 2.5 4 6

10 16 25 35 50 70 95 120

150 240 300 mm2.

The terminals have a rated connection

capability, which is at least two stages

smaller than the rated cross-section. The

conductors may be solid, stranded or

flexible and, if necessary, may have their

ends pre-treated. The rated cross-section

is verified using the gauges stipulated by

VDE 0660 part 100 table 7 (see page

W.14).

Rated current

Each rated cross-section is assigned a

particular test current stipulated by

VDE 0611-1. At these rated currents, terminals are not subject to non-permissible

increases in temperature.

mm2

A

1.5

17.5

2.5

24

4.0

32

6.0

41

mm2

A

10

57

16

76

25

101

35

125

mm2

A

50

150

70

192

95

232

120

269

mm2

A

150

309

185

353

240

415

300

520

Rated voltage

VDE 0611-1 / VDE 0660 part 100

The rated voltage of a terminal is the rated

insulation voltage to which the insulation

tests and creepage distances refer. It is

defined analogously to DIN VDE 0110-1,

and is one of the specifications marked

on the terminal.

Degree of soiling

DIN VDE 0110-1 / VDE 0660 part 100

The degree of soiling stipulates the influence of solid, liquid or gaseous foreign

particles, which may reduce the dielectric

strength or specific surface resistance

(see also page W.5).

Terminals for use in the industrial field of

application are assigned degree of soiling

3: either conductive contamination may

occur or, alternatively, dry, non-conductive

contamination which becomes conductive

in the likely event of condensation.

The minimum clearance distance is stipulated in combination with the rated surge

voltage in VDE 0660 part 100 or DIN

VDE 0110-1.

Operating conditions

Terminals can be operated under the

following normal conditions:

Ambient temperature 5 C +40 C,

mean temperature 24 h + 35 C

Altitude up to 2000 m a.s.l.

Relative humidity 50% at + 40 C, 90%

at 20 C.

CE mark

A EU directive stipulates that labelling with

the CE mark is carried out by the manufacturer. The mark indicates to the state

authorities that the item complies with the

relevant directives. It thus guarantees free

trade within Europe.

Conductor connectors from 50 V ~ /

75 V- comply with the basic safety requirements stated in the low-voltage directive

73/23/EEC (amended by 93/68/EEC).

CE marking acc. to the marking directive

93/68/EEC has been mandatory since

1 January 1997.

It is affixed to the packaging.

Declarations of conformity are kept available for inspection by the relevant national

supervisory agencies as part of the technical documentation.

SSB_W001-W044_GB.qxd

28.10.2003

8:57 Uhr

Seite W.21

Terminals

Mounting and end brackets

Dimensions

Terminal strips mounted from left to right

The overall dimensions of the terminals

with fastening parts are stipulated, but

without tolerances. A mounting tolerance

of 0.2 mm must be added to the terminal

width when planning projects.

Closed side on the left, open side on

the right

Open side of the terminal always closed

using end plates or partition plates

(WAP/TW; ZAP/TW and IAP)

End brackets placed at the beginning

and end of the terminal strip

End bracket not required next to PE

terminals. Exceptions: WDK/PE and

ZPE

Partition plate

The partition plate is necessary for visual

separation of circuits or for electrical

separation of neighbouring crossconnections.

Partition disc

Terminals

Combinations of different terminals

End plates or partition plates (WAP/TW,

ZAP/TW and IAP) must be used when

the contour changes.

For adjacent terminals with differing

rated voltages, end plates or partition

plates (WAP/TW, ZAP/TW and IAP)

must be used in order that the

respective rated voltages are adhered

to.

When the PE terminal is positioned next

to or between corresponding feedthrough terminals of the same series

and size, this does not influence the

rated voltage or rated surge voltage of

the feed-through terminals.

Partition discs can be retrofitted between

cross connectors or sockets in terminals

up to a max. terminal width of 12 mm.

Compliance with the rated insulation

voltage

The required stripping length for every

Weidmller product is stated in mm.

These lengths, such as < 6 mm 0.5

mm, > 10 mm 1 mm, must be adhered

to. This also applies when using ferrules.

The external dimensions of crimped

ferrules must comply with IE 60947-1

(1999 version).

Technical dictionary

General data

Assembling terminal strips

Working on electrical connection

elements with non-insulated

screwdrivers

Work using non-insulated screwdrivers

may only be carried out in disconnected

systems.

The following five safety rules must be

observed when disconnecting a system

before beginning work and in order to

ensure the system remains disconnected

at the working site for the duration of this

work:

Disconnect

Secure to prevent the system from

being switched on again

Ascertain that the system is not live

Earth and short circuit the system

Cover or cordon off any

neighbouring live parts

These five rules constitute the safety

precautions for working with electrical

systems and equipment. The measures

to be taken in accordance with operating

and local conditions, e.g. for high- and

low-voltage overhead lines, cables or

switchgear, are stipulated in detail in

VDE 0105 part 100.

Live terminals which are not in use

Any terminals which are not in use and

which could carry live voltage are to be

fitted with suitable covers (e.g. ADP 1...4)

to prevent them from being inadvertently

touched. The clamping screws of terminals, which are not in use, even those

that are not live, are to be screwed tight.

VDE 0105 part 100

Operation of electrical installations:

Work

Troubleshooting with two-pole voltage

detectors including voltage tester acc. to

IEC 61243-3.

W

W.21

SSB_W001-W044_GB.qxd

28.10.2003

8:57 Uhr

Seite W.22

Technical dictionary

General data

Terminals

Connecting terminals

Two conductors in one terminal

The optimum solution in terms of allocating conductors to individual circuits and

marking and organising individual functional units involves just one conductor

being connected to each terminal.

If it is necessary to connect two conductors with the same cross-section in one

terminal, then this may be carried out using

W-series terminals (screw connection).

DIN IEC 60999-1 does not prohibit the

use of twin ferrules for connecting two

conductors in one terminal point using

Z-series terminals (tension spring

technology).

DIN IEC 60999-1 prohibits the use of

screwless IDC terminals (I-series) for

connecting two conductors.

Continuous current for two

conductors

The total current of two conductors must

not exceed the continuous current of the

terminal. The continuous current is the

maximum current, which a terminal can

carry without the increase in temperature

exceeding 45 K.

Conductor connection with pressure

clamp for large cross-sections

It is now no longer necessary to force

conductors with large cross-sections into

the terminal: they can be inserted simply

and easily into the terminal block. All

terminal types are available not only as

individual terminals but also in block

versions with three-, four- and five-pole

blocks. All blocks are firmly screwed

together to offer additional distortion

resistance. Longitudinal holes in the

bottom of the terminals allow for direct

assembly.

Terminal blocks can be screwed directly

to mounting plates with a 25 mm grid.

Other advantages include:

constant transfer of forces with selfadjusting connection system

any mounting direction possible

finger-safe (VBG 4) even with crossconnection

extremely distortion-proof

Tightening the clamping screws in this

torque range guarantees:

secure, gas-proof clamping

no mechanical destruction of the

tension clamp

voltage drop far below the required limit

The test torque acc. to IEC 60947-1

(supplemented by Annex C1 of

IEC 60947-1-7 or the torque stated by

the manufacturer) is the lower value of the

torque range, at which all tests are

successfully passed.

The upper value of the torque range is the

maximum torque to be applied by the

user.

The electric screwdriver should preferably

be set to the middle torque of the

clamping torque range.

The table gives the generally applicable

values. Product-specific data are listed

elsewhere for the respective products.

Products with head screw with slotted head

Thread

Rated insulation voltage

The rated insulation voltage of the terminal

does not change when two conductors

have been connected correctly.

Torque ranges for clamping screws

Open cover and

remove screw unit

M 2.5

M3

M 3.5

M4

M5

M6

Torque range

Steel screws

min. 8.8

[Nm]

0.40.8

0.51.0

0.81.6

1.22.4

2.04.0

2.55.0

A 2/A 4-80

[Nm]

0.40.8

0.51.0

0.81.6

Products with head screw with slotted head

Thread

Cross-connection systems

Weidmllers WQV and ZQV crossconnectors are systems which are fully

insulated and finger-safe in the event that

they are directly (and inadvertently)

touched; they are available with different

numbers of poles (2-pole to 50-pole).

Note: the rated voltage is always reduced

when using cross-connections.

Insert conductor

and replace screw

unit

M4

M5

M6

M8

M 10

M 12

M 16

Partition plates or end plates must be

used with these cross-connections to

preserve the rated voltage.

Close cover and tighten

screw with Allen key

W.22

Cu 5 (CuNi 60)

[Nm]

0.51.0

0.81.6

1.22.4

2.04.0

2.55.0

Products with head screw with hexagon

Thread

Cross-connections which have been cut

off do not, however, offer this protection if

the cut edge is directly (inadvertently)

touched.

M 2.5

M3

M 3.5

M4

M5

M6

Torque range

NE screws

Cu 2 (CuZn)

[Nm]

0.40.45

0.50.6

1.21.9

2.03.0

Torque range

Steel screws

[Nm]

1.22.4

2.04.0

3.06.0

6.012

10.020

14.031

25.060

SSB_W001-W044_GB.qxd

28.10.2003

8:57 Uhr

Seite W.23

Terminals

Weidmller terminals are suitable for the

direct connection of solid round and

sector-shaped aluminium conductors.

Unlike copper, aluminium has certain

material properties, which have to be

taken into consideration when it is used as

a conductor in electrical systems.

When exposed to air, the bare surface of

the aluminium immediately becomes

covered with a thin, non-conductive layer

of oxide. This increases the contact

resistance between the aluminium

conductor and the busbar in the terminal.

In the worst case, this may develop into a

so-called glowing contact.

In the case of stranded conductors, this

phenomenon is exacerbated by the

contact resistance of the individual wires.

Despite these disadvantageous

properties, aluminium conductors can be

connected to Weidmller terminals if the

reduced rating currents for aluminium

conductors and the following assembly

instructions are observed:

1. Carefully clean the oxide layer from the

stripped end of the conductor, for

example using a knife.

Caution: do not use brushes, files or

sandpaper, to which aluminium particles

may adhere and be transferred to other

conductors.

2. Immediately after removing the oxide

layer, rub neutral grease such as acidand alkali-free Vaseline into the end of

the conductor and connect it directly to

the terminal.

3. After disconnecting the conductor,

repeat 1 and 2 prior to reconnection.

4. The instructions only apply to solid

round or sector-shaped aluminium

conductors.

Technical dictionary

General data

Use of aluminium conductors

solid round or sector-shaped

Terminal type

Rated cross- section

W-series

WDU 2.5

WDU 4

WDU 6

WDU 10

WDU 16

WDU 35

WDU 70

WDU 120

SAK series

SAK 2.5

SAK 4

SAK 6

SAK 10

SAK 16

SAK 35

mm2

2.5

4

6

10

16

35

70

120

stranded

W-series

WFF 35

WFF 70

WFF 120

WFF 185

WFF 300

Reduced rated

Thread size of

current when

terminal screw

connecting an

aluminium conductor

A

20

M 2.5

27

M3

35

M 3.5

48

M4

64

M5

105

M6

163

M8

230

M 10

Tightening torque

Nm

0.5

0.6

1.2

2.0

3.0

4.0

10.0

15.0

2.5

4

6

10

16

35

20

27

35

48

64

105

M 2.5

M3

M 3.5

M4

M4

M6

0.5

0.6

1.2

2.0

2.0

4.0

35

70

120

185

300

105

163

230

300

409

M6

M8

M 10

M 12

M 16

3.0

6.0

10.0

15.5

30.0

Tips during installation:

When tightening the terminals, it is

advisable to hold up the conductor to

avoid deformation to the mounting rail and

to keep the foot of the terminal free of

torsion forces.

Stranded aluminium conductors are

connected to terminals using an

aluminium cable lug selected according to

its conductor shape and connected by

following the instructions issued by the

cable lug manufacturer.

Fastening screw

Aluminium side

Aluminium

cable lug

Aluminium

Copper-plated

aluminium washer

Copper side

conductor

Busbar

Copper-plated aluminium washers are

necessary for the transition from aluminium cable lugs to the busbar of the

terminals. This is the only way to ensure

reliable transition from copper to aluminium. The washers are fitted so that the

copper side is in contact with the busbar

and the aluminium side with the aluminium

cable lug.

W

W.23

SSB_W001-W044_GB.qxd

28.10.2003

8:57 Uhr

Seite W.24

Technical dictionary

General data

Terminals

Definition of the various types

PE terminals

Fuse terminals

Multi-storey distribution terminals

Fuse terminals consist of a terminal base

and a fuse insert holder.

A multi-storey distribution terminal is a unit

with clamping points for connecting

and/or linking external, neutral and PE

conductors to their fastening support with

a conductive PE connection.

PE

A PE terminal is a component with either

one or several clamping positions for

connecting and/or branching PE conductors (PE and PEN conductors) with a

conductive connection to their support.

Partially insulated PE terminals are

insulated from adjacent live parts of

terminals; the partial insulation is marked

green/yellow.

Scope (IEC 60947-7-2)

This standard applies to PE terminals (with

PE function) up to 120 mm2 and to PE

terminals (with PEN function) for sizes

upwards of10 mm2 with screw clamping

points or screwless clamping points for

connecting round copper conductors with

a cross- section between 0.2 mm2 and

120 mm2 (AWG 24/250 kcmil) for circuits

up to 1000 Vac 1000 Hz or up to 1500

Vdc. PE terminals are used to produce the

electrical and mechanical connection

between copper conductors and the

fastening base.

PEN function

Acc. to IEC 60947-7-2, only copper

mounting rails may be used for application

of the PEN function. Steel mounting rails

must not be used.

TN-C system supply

from 16 qmm

PEN-bridge

WQB

Einsatz der TS 35 x 15

Use of TS 35 x 15

In order to comply with the current

capability required by IEC 60947-7-2, the

TS 35 x 15 mounting rail must be used for

PE terminals with a rated cross-section of

16 mm2 and upwards.

W.24

In the case of fuse terminals for lowvoltage fuse inserts (D-system), the

technical data are defined by IEC

60947-7-3 in conjunction with VDE 0636

part 301.

In the case of fuse terminals for device

protection fuse inserts, the technical data

are defined by standard IEC 60947-7-3

pertaining to the specific range of

applications of these products.

Fuse terminals for device protection are

rated for a certain maximum power loss

on the basis of standard IEC 60127-2

valid for G-fuse inserts.

The product pages contain details about

the maximum power loss for individual or

composite arrangements for short-circuit

and/or overload protection.

These terminals can be fitted on top of or

next to each other and assembled to form

terminal strips.

They have several connection levels, all of

which are isolated from each other.

Scope IEC 60947-7-1 / IEC 60947-7-2

DIN VDE 0611-4 (partially)

These standards apply to multi-storey

distributor terminals with clamping points

and screw connections, and/or screwless

connections for connecting or linking

solid, stranded or flexible copper

conductors. In distributor terminals,

external conductor and/or N and PE

conductor connections are all present

together within a confined space.

The N-conductor can be divided for

insulation measurement; it is not used

for disconnecting or switching.

SSB_W001-W044_GB.qxd

28.10.2003

8:57 Uhr

Seite W.25

Terminals

Neutral conductor isolating terminals

Technical dictionary

General data

Definition of the various types

Measuring and isolating terminals

Isolating terminals

Measuring and isolating terminals are

used for partial disconnection of circuits

for measuring purposes in unloaded state.

Isolating terminals are used for operational

disconnection of circuits in unloaded state.

NT

A neutral conductor disconnect terminal is

a unit with clamping points for connecting

and/or linking neutral conductors with

disconnect connection.

These terminals can be fitted on top of or

next to each other and assembled to form

terminal strips.

Rated voltage

IEC 60947-7-1

IEC 60947-1

The rated voltage given conforms to IEC

60947-7-1. It is the rated insulation

voltage and is defined acc. to IEC 60947-1

or IEC 60947-7-1.

400 V applies to

external conductor / external conductor

The rated voltage of the measuring and

isolating terminal is the rated insulation

voltage, to which the insulation tests and

creepage distances refer.

It is defined acc. to IEC 60664-1 and is

one of the specifications marked on the

terminal.

The opened disconnect point is

dimensioned according to the allocated

rated surge voltage.

The rated voltage of the isolating terminals

is the rated insulation voltage to which the

insulation tests and creepage distances

refer, and is defined acc. to IEC 60664-1.

The opened disconnect point is dimensioned acc. to the rated surge voltage

allocated for devices with disconnect

function acc. to DIN VDE 0100-537 and

IEC 60947-7-1.

The disconnects of the isolating terminals

are rated for unloaded actuation (use

category AC20 acc. to IEC 60947-1) and

used to clear a system or part of a

system.

250 V applies to

external conductor / N-conductor

external conductor / PE conductor