Precision Measurement Techniques in Engineering

Uploaded by

yashar2500Precision Measurement Techniques in Engineering

Uploaded by

yashar2500!

Practicel

Engineering

MA1001

Measurement

in measurement

standards

Environmental

standardrcoms,metrologylaborabrlcsand Inspecdon

roomsrcqulrca contsolledenvhonnEntso thet

precislonmeasurcments

can bc carrledout. Ttrc

agreedtempcrfrrrc for prcdsion

Intemauonally

ig 200C,The ncadfor a constant"

mcasuremnt

standardtempcratureIt csscnualbecauscmost

materlalsc)gandwhcn heatedand confad wicn

coolcd,Thls not only #ects the llneardirncnsionsof

comporrcnbbut [Link] ls

rnoctllkdy to occurIn asscmbllcanradcfrom

dlfiarcnt rnaterlalswltfi dlffercnt Gtes of ogansion

whensu$ect to thc safitctemperahrrcchange.

Ruler

+I

| *Madefromspring

plated,

I rted, usually

I prefvablywitha

I mffi finish.

e 150mmruleisthe

mostcommon.

olAccurate

to 0.5mm

Iuarht

dtadh'id

[Link]@:Nlk

Vernier

caliper

+-

Cusedfor oGemal

andintemal

measurement,

and

for

sometimes

depffi.

*Usualsizeis 150

mm

tAccurateto 0.05

mmor 0.02rtrm

(L rfftaol

ft. !.rrar

-aa

Micrometer

C.?,, -_ [Link] I

/Ao

+l+usesa 0.5mmpitch

&

I screwthread,and a

I banel calibratedinto

* -,;

j so oivisions.

i+[Link]

SRangelimitedto 25

mm, so sizes;

0 -25,25 - 50,50 - 75,

etc.

!i+.5",

tI

I

l

l

i

I

"Accuracy

i +fne greaterthe accuracydemandedby a

I designer,the narrowerwill be the tolerance

I bandandthe moredifficultand cosUywill it

withinthe

I be to manufacturethe components

[Link] the tolerancegets bigger,

tfie dimensionbecomeslesspreciseand

easierto [Link],for easeof

manufactureat minimumcosqa designer

neverspecifiesan accurasygreaterthan is

necessary

to ensurethe correctfunctioningof

the comDonent.

Avoiding

cumulative

errorc

Tftoma

; CBy measuring

i dahlmthe problem

erors

I of cumulative

i rsawoeo.

i

@+

|

I

|

MA1001 EneineerinePracticeI

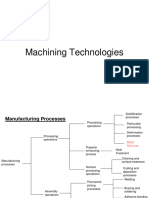

ManufacturingProcesses:

Removingmaterial

1.

Turning (centre lathe)

To removematerialby turning, the lathe has to rotate the work piece and guide the

tool.

Sprnf\g

3p...[

g*- {.".n.

ca.o,5!^de-

([Link] rcur"L

s LJ e

[Link].r(

.tr ge^v

ircin

Taitstoc K

SvavoL

Le^"L

?a-o.

Travqr5s

SpiJL

Scve,>

fravev'si:,

:\^{

yevefs<,

9*lo[|<Apvon

rwv

cLutch

f5r[

Cabinet & base

Fe.o(

3eo, Lrnr

Parallel (cylindrical) turning

|oda-r

P u^p

[Link]

The work can be held in a chuck, and the tool is fed into the work by the movement of

the carriage along the bed and the depth of cut controlled by the cross slide.

Axis of rotationof

and w orkpi ece

Saddle (caniage)

Barrelmovementwithin

tailstock

Barrel(poppet)

Tailstock

.| (loose head)

Headstock

( fas t head)

,?.

--+

Toi\stoc((

Basi c a l i g n m on t

Movementof saddl eal ong

bed parallelto axisof

rotationof the spindle

The carriage or saddle provides the basic moyemant

of the cutting tool parallel to the work axis

l Mov ementof

tai l s toc kal ong

bed parallelto

s pi ndl eax i s

Perpendicular (facing) tuming

The work is usually held in a chuck and the tool moves perpendicularto the spindle

axis bv the cross slide.

Micrometerdial controllino

compoundsl i dew hen

providingin feed to the tool

M i c r o m e tedr ia lco n tr o llin g

C r O S S - Slrwn

Oee n Pr OVtOtn o

i n - f e e dto th e to o i wb ilst

c y l i n d r ica lly

tu r n in g

Cutting angles applied to a single point lathe tool

Tool height is very importantwith turning tools. The centrein the tailstock is often a

usefulplaceto checkandadjustthe cuttingtool to the correctcentreheight.

Rakeangle

is reduced

\

90'

R"t

" "nsr"

ls IncreaseiJ

(a) Tool set correctly

o n co n tr e h e ig h t

(b) Tool

".t

height

Clearance

a n g l ei s

increased

Lru,[Link]

1 C l earance angl e

\ ts reduced so

that it is no

Ionger affective

and the tool rubs

(c) Tool set [Link]

hei ght

Drilling machines

To remove material by drilling, the drilling machine hasto rotate the drill and provide

a meansof feeding the drill into the work piece. Usually the hole being drilled has to

be perpendicularto the datum,surfaceof the work piece.

eieppe.t

'stQPPd[ puilq

Putl4/t

.lp"e.t ch*'[Link]

"

l-ga

tse\t

Belt guard

Aotor

Csntrots

hotn ctte'.

[Link]

:91"4\e Qo.g

PePlh

c\$ (l

5a^l5'

5toP

C\rvcK

Spindleaxis----1

Be n ch d r ilti ng machi ne

The spindlerotatesandlocatesthe drill andis itself locatedin precisionbearingsin a

sleevethat canmovewithin the body ofthe drilling [Link] spindlespeedcan

be adjustedby alteringthe beltpositionon the [Link] feedis operated

by handthroughtherack andpinion mechanism.

This type of feedmechanism

enablesthe operatorto 'feel' the drill cuttinginto thework piece.

Spindle extension

Stepped driving pulley

Pulley journal bearing

Bearing spacar

Pulley journal baaring

spindle journal

b6aring

Rack

Pi ni on

Sleeve lock

Grease nipple

Guard

Thrusl race

Lower spindle journsl

bsaring

Drift slot

Spindle

'1. ci'ctgr*,cr1

M or s etaper {

L.

s r z e.J

Other operations which can be performed on the drilling machine are;

/4W

eFot

Cgv ntcrbo'ix1

C*9 t"^&

3cY.r{3

L)

(o.i-1

To producedimensionallyaccurateholesa machinereameris [Link] requiresa

hole slightly smallerthanthe onerequiredto be drilled,(approx.0.5mm smaller),and

thenthe machinereamerfitted to the drilling spindleto finish the machining

operation.A lubricatingoil is oftenusedwith the reamingoperationto achievea high

qualitysurfacefinish.

,&"Eamd

Reamers

Ream?ers

Para!ileEffiact'aEme

STRAIGIITSHAT\JK

TAPERSl-lAt',lK

Milling machine (vertical)

The basic alignments and movementsof a vertical milling machine are shown in the

diagram below;

. >\c

t"\g-t c.i.

l";"-\

g/s tuv t

L,rtir,r;

-\

Tilting head

V ari abl e-speed

spi ndl e motor

B ack gear

Motor speed

COntrol

Motor directton

control

Coolant on,/ofl

swilch

Motor direction

control

Spindle feed

hand s,heel

(.n re

,

Spindle nose

c[[Link]^l

\ar.I\e

Cross-

"u.

r(krb\ t-

t "-.,"\ q\s"{'

lraverse

handle

Reduciion

gear box

Tobie-

Table

travers

mrcromeler

Knee lock

{-*".L 1.*t

b"i

tv*w.r;e

Cootant

pump

rnolor

( e' '

k""" ste^f

Ease and

coolant surnp

LKvre*

h..". I t .

Some typical cutting operations performed on a vertical nilling machine;

(a) Usinga facemillto Produce

a olanesurface

(b) Usinga shellendmillto

producea step

(cl U soofa.

This'blind'keyway

wouldhaveto be sunk

witha,

Thisrecesscan bs cut with

an ENDMILLsincecutter

canworkin fromthe edge

of blank.A slotdrillcould

alsobe used

of

Applications

theslotdrill

Thisrecesswouldhavet9 be

machinedwitha -3lot drills

whichis the only cutler that

willworktromthesolid

(d) Useol slotmillsandenddrills

.cutl er

7 ' ? l I o (z o " J

MAL001 EneineerinePracticeL

LIMITS AI\D FITS

a componentto the exactdesignsize,this sizebeinga

It is impossibleto manufacture

numericalvalueof [Link] overcomethis difficulty, a toleranceis permittedor

'tolerated'which is the amountof deviationfrom the givenbasicdesignsize,or the

reasonableinaccuracyin manufacturing.

margin of error, allowableto accommodate

d

'J

\Y

N

On a drawing,this toleranceis indicatedby thg maxiqumand minimumpermitted

\lo.r" .u^?83shownin the diagram

sizes,which arecalled upEe(

^.."1

shouldbe statedonly whenthe requiredaccuracyis essential.

[Link]

p,

tn

o r{

t<

NI

'{

Clearance lit

This is a fit which provides a clearance: hence the shaft is always smaller than the

hole into which it fits. Clearance is the positive difference between the sizes of the

hole and the shaft.

I

na,n

Typicalapplicationsof

pulleys,bearings,etc.

cfeornnr.

loosepulleys,

fast

U1,ffi":.i::tating

shafts,

Interference fit

This is a fit which always provides an interference; hence the shaft is always bigger

than the hole into which it fits.

y,.61-a

s-{-eor,+nce-

'r'^tn intetle(ence-

Typicalapplicationsof the interferencefit areon pressed-inbushesor sleeves,crank

pins,shrunk-oncouplings,railwaywheelsshrunkon to axles,etc.

[Link] ol /on.

a

t.

h*t ,*J @,[

Transition fit

This is a fit which may provide either a clearanceor an interference;hencethe shaft

Arq

[Link]

Typicalapplicationsofthe transitionfit areon bushes,spigots,fasteners,

pins,keys,

stationarypartsfor locationpurposes,etc.

Determiningworking limits

In orderto decideon a desirablefit, the functionof the assemblymustbe considered.

The shaft is going to rotatein the bush,hencea clearancefit is [Link] bushis

goingto bepressedinto the bracketboss,hencean interference

fit will be appropriate.

75

-qt|'l

*3o

+5t

+31

'

7b

I

y+o

+' 39

a6,

\f

tc\ O

rl \'r

rJ\

:-

r--{l

I +____t

sr, LH_IJ^

g

d8 r

oa

n0c]

o dl _

pF

An

oo

P ol

+ \$ .

\

SHAF T

B OS S

Calculatethe maximumandminimum limits forthe following shaftandhole nominal

sizes:

a)

5 0mm

H l l /cl l

b)

100mm

H7ln6

c)

150mm

H7ls6

1 r" +tio

l, u il, 0

\I

1'roo

1 y=

t5 o

fl 1

5o"t(,0 -, 1+t'sro

e lo. o, , f ; \ + t ' + , o

i7 o , O 3 5

/ , r r .' ,ooo

l5o.o4o

r [Link]

f io o

\ ^o

5

tco,o+5

t oo. ozP3

(50" tz5

ifo ' ioo

fkd i

I r()tn

l l s . l 5tX ): 1 9 6 9

rs Hl

{ N{

Dl

StrLtrCTE)ISO F'ITS--HOtr BASIS

[Link] lil$

Transilion fits

)'ral

4500A

l!s0c l. I'ibrunrt

1970

lnlcrfcrcnce lils

+

Dixgr.m lo

$ale fot

!5 mm. diNmclcr

He

Y / / l r AHil

WA

He

WA - W4

HO

H7

772

r77Z

.}"

ts\ss

t7

n:

K\\\\

N\\\\

H7

7777V

H7

rv7

k6

H7

r-Zi7-z

n6

N\sll

H7

?777V

H7

17777)

--d-

r6

Fs\ll\

Holcs

t-\\\

h6

Q9

d to

Sho I ts

\ominrl

Orcr

'lirlcrancc

sir(s

'lit

lill

0 0lll nrnl

l

I

l0

l0

t8

l0

40

50

65

80

r00

r20

t8

l0

40

50

65

80

00

20

140

40

60

r60

80

r80 200

200

225

250

280

:\l5

155

400

T5

150

180

3 t5

+6 0

0

+? i

0

0

+ ll0

(l

+n0

0

t

0

+ 160

o

+ r90

o.

+ r90

(,

+ ?20

0

J

f ) l)

o

o

+ 150

o

+ t50

0

0 l|()l nrnl

- 60

_D0

_70

- t{o

- t70

- 95

- :05

80

- D0

290

- t40

- 1lo

-l 50

ts

0

dt0

0 001nrnr

H9

0 001nrnr 0.001 nnt

- 20

_60

+25

0

-lq

+.10

0

- 10

+ .10

o

+ l()

- .:o

- 50

-{o

- qa

*50

- l?o

- 65

+ 16

0

+ 4:l

6l

?s

+ Jl

0

o

!11

tl

[Link]""

a1

il7

0 001 trrnr

0 001mm

0 001 nnl

{) 001 nlnr

J. l4

0

-6

- t6

+10

0

-l

_E

+ l!

o

+ t5

0

-{ l?

-) t.l

+t8

-6

+l

r

0

t)

- .t0

* 97

F 27

o

+ .ll

o

- tl

- 28

_t6

_1,

4l

+61

0

- 50

- | tl

+ :19.

0

-25

-J0

+ 7{

- 100

+71

0

- 60

- ll{

+46

0

- .t0

-60

+10

0

+ ri7

0

- t2 0

- 260

f8?

0

- 12

- t59

+J 4

o

+ too

o

- t{ 5

* 105

+ too

- 81

- t85

+ 6.1

.o

_16

- 81

Tolerence

h6

+10

0

0 001 mm

+ 12

0

'l

20

lt

0 001 nrm

0 001 nrrr

H7

n'l

no

0 001nrrn 0 001 nldl

p6

0 001nrnr 0 0{,1 nrnl

+10

+10

+10

o

+t2

0

+

+

+l?

+16

+15

o

+t8

+ 15

0

+18

+ 12

o

+ 15

+21

0

+ 15

+ tt3

+ 25

0

+ 1.1

+ 17

+ 25

'0

+ .r0

o

+19

+20

+t0

t- l8

0

- lt

0

+21

0

t<

k6

ll

o

+l?

l9

t0

+ 18

+28

tl

'I_olcrrncc

l'olcrrncc

+6

+0

fl1

Tolerancc

+10

0

-6

+21

n

- 80

- t80

s6

ll?

|61

0

Tolerancc

0 01)l Dnr

1l

+ lx

+lJ

l<

- t6

0

-t0

-29

+t0

0

- 19

0

+.t5

0

- 14

+ :t5

0

- 22

0

+.15

0

+ 15

+l

+ 15

U

+45

+ll

+ .lj

0

+59

+17

fd0

0

-J9

+i 0

0

- 25

0

+40

0

+28

+l

+{0

+52

+27

+{0

0

+6E

+ J.l

0' (

+21

+10

0

+ ili

0

t70

J5J

+ lt5

0

* t00

- l tJ

tJ

+ [Link]

0

- t90

- 400

+ n0

c

-ilo

- ?t0

+81

0

- 56

- lotr

+ H0

_62

- l 19

+51

0

+ 6.1

- 10

- 60

355

100

+ .160

{W

(,

-IO

- 4.10

l. t{ 0

0

- | ]5

- 265

+89

450

+ 400

o

+ .lu)

o

- 4.10

- 840

+ r 55

- 2.10

- {tto

+ l5 - r

o

-n5

- 190

te7

0

S l a ck fil

+16

0

+46

0

- 19

0

+.t6

0

+.1.t

+4

+ l(l

0

+60

+ .11

+ 10

0

J- 20

+ t4

+ t!

0

+ 2l

+15

o

+t8

0

+21

+{l

+16

5l

.12

+J6

0

0 001 mm

(,001 nrnl

+ 1e

+J0

(,

Il80

Loorc fil

Eait tir

(,

6ll

[Link]

N or m al fi l

51

- t7

( l os c l i l

B r it is lr S ta n d a rd d a ta s h e e t BS 4 5 0 0 41 sel ecredIS O hts * hol e basi s

t8

5.1

+.16

+J

+57

0

- 16

0

+ )/

o

+..10

+61

0

- .10

0

+61

0

+ .15

Sl i dc Ii l

-F5

t ' rrs h f i l

+66

+.lJ

tr- 5)

tl

+ llt{

+56

+ r7

0

+ 7.1

+J7

o

+ 9lt

+6:

+ 6.1

0

+80

+ .10

+ 61

0

+ 108

+ 6ti

l )rrs s l i l

+ 19

+ t)

:19

+48

l0

l8

30

40

50

+72

+78

65

+ .15

0

+.15

o

+40

+91

+11

+ l0l

1- lt)

-t- | t7

80

00

20

+40

0

+40

o

+46

+ r25

+ t00

f-

l

I

+16

5r,

,TO

3

3

6

+ 10

n

sircs

ntnl

+ .t0

t)

t0

l8

30

40

50

65

80

100

120

140

t60

60 tB0

BO 200

200 225

40

6(.,

225

t5

v0

+5

t)l

250 280

280 315

+Jl

+ :16

+57

0

+:{.1

l )ri rt ' f i t

Orer

+ 5r)

+ .1.)

+46

0

+ 160

- 50

- 96

s6

+ 20

+15

\ominrl

il7

+6

tlo

260

550

280

570

- :l0u

6:0

- :l-]o

- 6J0

_ .160

-r50 -500

[Link]

H8

c9

- 480

+ :120

0

+ :120

170

i90

t80

400

200

- 2t0

- {60

+ 190

0'

+ 290

0 001 mnl

!t

1{0

'I olrrencc

folcrancc

lt9

cll

(t.l

0

+ ('l

r- 19

l ' o rc c I i l

315

355

400

450

250

355

400

450

500

MA1001EnqineerinqPracticeI

Presswork

Thereare threedifferentwaysof coldworkingsheetmetalin presstools.

Theseare:

1. [Link] thiscasethe requiredshapeof workis shearedfromthe

to [Link]

metatstrip,the metalbeingdeformed

variationsof shearing;

(a) Blanking,in whicha blankis punchedfromthe strip,the blank

removedby the punchbeingthe [Link] metalleft is

[Link] die is madeto the requiredsize,[Link] punchis made

smallerthanthe die by the amountof clearancerequired.

Waste

Tillilil

/

ffi'+

a:

Strtp leed

Requlred Part

(aJ Blanklng

(b) Piercing,in whichthe blankpunchedor piercedfromthe metalstripis

The piercingpunchis

waste,the holeleftin the stripbeingrequired.

beingaddedto the die.

madeto the correctsize,the clearance

FLerqlng

Tilil

Stnp feed

Regulred

part

(b) Piercing

(c) Cropping,in whichthe pieceblankedfromthe stripis waste,the strip

leftwiththe croppedendsbeingthe requiredpart.A croppingtoolis,

a blanking

tool.

in principle,

Strip feed

Requlred part

(c) Cropping

-Top sct

Pressurc plat

[Link] punch

Punch plate --J

'

\

' r't | ['tt '

Piercing punch

Strigper

Bottom set

The diagramabove showsa pierceand blankpresstool. This is a simple

shearingtool, and the punchesand die can be of any [Link]

tool shown has the main featuresof any presstool that we will examinein

more detail.

r 1l

lr- rr,.:ln f ?,r,tc*,.. [Link].r.:.{.

Punch

Madefromnon-shrinking,

non-distorting

alloytoolsteel,suchas a high

[Link]

carbon,highchromium

andground,and

are heldin a [Link] shanksmaybe a drivefit in the punchplateas

[Link] usedto manufacture

the requiredholes

veryaccurately

in the punchplate.

Die

Madefromthe samemetalas the punch,and likethe punchis re-sharpened

by grindingthe top [Link] shapesmaynecessitate

the die being

madein morethanone [Link] profileis 'backedoff withtaperas

shownto allowthe blanksand piercingslugsto easilyfall clearintotote boxes

positioned

underthe pressbed.

Stripper

Thisis usuallymadeout of mildsteelandis a clearance

fit for the punchesat

the top, and the stripat the sidethat it guidesintothe correctpositionunder

the [Link] stripperpreventsthe metalstripliftingup with the punchas

the [Link] alsoprovidesa meansof housingthe stops.

Sfop

Thereare manyformsof stops,the one shownbeinga simplespringloaded

[Link] the stripis pushedunderthe stopit ridesup overthe stripto drop

intothe spaceleftby the [Link] the stripis thenpulledbackagainstthe stop

(againstthe directionof feed),the stripis correctfylocatedfor the next

shearingoperation,leavingthe minimumof wastemetalbetweenthe blanked

[Link] to a stopcan be carriedout at highspeedby

the operator,anda welldesignedstopmustbe simpleandefficientin use.

Morecomplextoolsrnayrequirernorethan one stop,and arrangements

can

be madeto operatestopsby the moven'tent

of the pressram if desired.

Automaticfeeddevicesdo not requirestopsas the stripis automatically

movedalongthe correctpitchlength,betweeneachstrokeof the press.

Pilot

Theseare heldin the blankingpunchand are a clearancefit for the pierced

[Link] the ramdescends,

piercedholeand

the pilotlocatesthe previously

positions

the stripmorepreciselyunderthe [Link] used

wherethe relationship

of piercedholesto a blankprofilemustbe precise;

thereforea stopinitiallypositionsthe strip,butthe final positioningdepends

uponthe [Link] can be seenthenthatthistechniqueis idealfor a rollfeed

press,whichhas no stopsuponthe tool.

DrbSefs

Thesemaybe madefrom mildsteelas theyare bolstersto whichthe die and

punchassemblies

are [Link] set holdsthe shankby meansof

whichthe punchassemblyis locatedand heldin the [Link] bottom

set is boltedor clampedto the pressbed in the correctrelationship

to the top

set so thatthe axesof the punchesanddie holesare in line.

Castirondie setsare commercially

available

whichare madecompletewith

guidepins and [Link] top set can alwaysbe locatedin exactly

the samepositionrelativeto the bottomset. The presstool-makerthen

ensuresthatthe punchand die are alwaysa perfectfit whenthe tool is

[Link] makesthe settingoperationon the pressquickand easy,

becausethe completetool is simplymountedand fastenedon the press,no

locatingbetweenpunchand die beingnecessary.

PressurePlate

This is a hardenedand groundsteelplate,whichis insertedbetweenpunch

and top set, in orderto takethe impacton the headof the punchas it shears

throughthe strip.

2. Bending.

Punch p[ate

Locatlng btocks

Bottorn set

The metalblankreadyfor bendingis positionedon the die in the locating

[Link] punchdescends,andthe work is heldbetweenthe punchface

andthe [Link] and punchcornerradiishouldbe

as largeas possibleto assistforming,and preferablynot lessthantwicethe

thicknessof [Link] pressurepadejectsthe componentafterforming.

.\

in_ trr,e I

d,ust cxg

Pc.vt5

.=-to'(*-1<-

\s

,no

Gv"e- in

*q

I here

C-,a:t

p,cxYt5

0.55{"Ttt.,L'

,";

l J^

II

{,<.

1-- t

**I

CcrQ rt.r[

Y^ru

';;to rrot\e

\3

of t"..o.l.'

[Link] diagrambelowshows a typicaldrawingtool in which a blank

is beingdrawn into a cylindricalcup. The work is shownin a partialiy

drawnstate,the punch not yet having'bottomed'.

Punch

Presgurepeds

Bottorn set

Drawingtool.

The springloadedpressurepadon the punchkeepsthe metaltightagainst

the die face,andthe blankis ironedout as it is dravrrn

overthe radiusededge

of the die [Link] the cupand keepsthefinishededge

of the [Link] pressurewhichis appliedby thispadis important;

no

pressuregivesheavywrinkfing,and excessivepressureresultsin the bottorn

beingpressedout of the [Link] optimumpad pressuregivingbestresults

varieswiththe type of work,butwill be to the orderof 30 to 40o/o

of the

drawingpressure.

Practice1

MA1001Enqineerinq

Processes:Polymers

Manufacturing

POLYMERMATERIALS

Polymerscan be dividedintotwo groups-thermoplastics

and thermosetting.

materialscan be softenedand re-softenedindefinitelyby the

Thermoplastic

of heat,providedthetemperature

is notso highas to cause

application

Suchmaterials

can be formedintodifferentshapesby the

decomposition.

(polythene),

applicationof [Link] suchmaterialsare polyethylene

polyvinylchloride(p.v.c.),polyamide

(Nylon),polycarbonate

and cellulose

acetate.

materialsundergoa chemicalchangewhentheyare subjectto

Thermosetting

heat;this changecannotbe changedby the applicationof furtherheating.

(Bakelite),

Typicalthermosetting

materials

are phenolformaldehyde

urea

formaldehyde

and melamine formaldehyde.

polymershaverelativelylow densities,

Boththermoplastic

and thermosetting

relativelylow strengthand stiffness,low electricalconductivity,

low thermal

lowspecificheatcapacity,highcoefficient

conductivity,

of thermalexpansion

and are softenedor degradedat temperatures

not far removedfromthe

boilingpointof water.

For mostpurposesothermaterialsare addedto the polymerto makethe

materialfor processing

intoproducts,

the termplasticgenerallybeingusedfor

this'mixed'material.

The additivesmaybe in the formof solids,liquidsor

[Link] purposeof the additivescan be eitherto improvethe properties,

or addcolour.

reducethe cost,improvethe mouldability,

The followingare sometypicalexamplesof additives.

Glassfibrescan be

andto makeit lessductilebut

addedto improvethe strengthof the material,

[Link] addedto improvethe [Link]

of the materialduringprocessing,

be addedto improvatheflowcharacteristics

polymer

[Link]

the liquidactinglikea lubricantbetweenthe

additiveis a gas,the resultbeingfoamedor expandedmaterials.

FORMING

PROCESSES

The processesusedwith polymerscan be consideredto be dividedintotwo

groups-primary

processesand secondaryprocesses.

Primaryprocesses

involvethe fabrication

of the component

in a single

polymer.

Casting,moulding,extrusionand calendering

operationfromthe

are

Withsecondaryprocessesa productof a

examplesof suchprocesses.

primaryprocess,e.g.a sheetof polymer,is transformedintoa finished

[Link] machining

areexamplesof suchprocesses.

Moulding

I

C.h<-op

fcoce-e=

In1-ection

moulding

andto someextentfor

A widelyusedprocessfor thermoplastics,

materials,

is injectionmoulding.

In thisprocessthe polymeris

thermosetting

A rotatingscrew,or a ram,then

fed intothe coldend of the injectioncylinder.

the materialand passesit througha heatedsectionand then

compresses

injectsthe polymerintothe [Link] the caseof thermoplastic

materials

the

mouldhas'[Link] materialhassufficiently

cooledthe

is ejected.

component

materialthe sameprocedureis adoptedbut the mouldis

Witha thermosetting

heatedand the componentcan be ejectedwithoutwaitingfor the component

to cool,thoughthe materialmustbe heldin the mouldfor a sufficient

timefor

production

possible

rate

with thermoplastics

the curingto be [Link]

is fasterthanthatpossiblewiththermosetting

materials.

Complexshapeswith inserts,holes,threads,etc can be producedbut

enclosedhollowshapesare [Link] beeror milk

bottlecrates,toys,controlknobsfor electronic

equipment,

tool handlesand

[Link] sizeof the productscanvaryfromthe controlknobsize,a

massof perhaps15 g, up to palletsperhaps1.0m squarednd havinga mass

of manykilogrammes.

The costof the mouldsusedwithinjectionmouldingis highandthusit is only

withlargeproduction

runsthatthe [Link]

thereis littlewasteof materialin the processandthe partstakenfromthe

mouldare finishedproducts.

Transfermoulding

mouldingandtransfermouldingare usedwiththermosetting

Compression

[Link] compression

moulding

the powderedpolymeris compressed

betweenthe two partsof the mouldand heatedunderthis [Link]

transfermouldingthe powderedpolymeris heatedin a chamberbeforebeing

transferredby a plungerintothe mould,q processnot unlikeinjection

moulding.

The costsof mouldsusedwithcompression

mouldingtendto be lowerthan

thoseusedfor eitherinjectionor transfermoulding,

thisis becausethe mould

polymer

is simplerwith no accessfor the molten

havingto be [Link]

mouldinginsertsmaypresenta problem,beingdamagedor

compression

movedwhenthe pressureis [Link]

complexpartswith insertsto be readilymade.

mouldingis usedto produceproductssuchas washingmachine

Compression

plugcases,switchcases,knobs,car instrument

panels,

electrical

agitators,

etc.

Fqtdarcd

polymcr

Moulrl

Mould

Compressionmoulding

Transfermoulding

Extrusion

Extrusion

Withthe extrusionprocess,moltenpolymeris forcedthrougha [Link]

doneby a screwmechanismwhichtakesthe polymerthrougha heatedzone

beforeforcingit throughthe [Link] operationis continuous

with a steady

sourceof moltenpolymerbeingforcedthroughthe [Link]

constantcross-section

are [Link] processis usedwiththermoplastics for the productionof pipesandvariousprofilessuchas curtainrails,

sealingstripsand skirtingboards.

lf thinfilmis required,

a die can'beusedwhichgives,anextrudedcylinderof

the [Link] is inflatedby compressed

air to give a

methodis to usea slitdie and allowthe hot

sleeveof [Link] alternative

intoa [Link] may

materialissuingfromthe die to fallvertically

be a waterbathor a pairof [Link] eitherof

thesemethodsis usedfor packaging

and a varietyof decorative

and office

USCS.

Sheetcan be extrudedby usinga horizontal

die of the appropriate

shape.

processing,

Suchsheetmayb usedin secondary

suchas thermoforming,

to

formproductssuchas dinghyhullsand containers.

Corrugated

sheet

producedthis way is usedfor roofing.

.

Blowmoulding

An importantextrusionprocessis [Link] processis

[Link]

usedfor the productionof hollowarticles,particularly

operationinvolvesextrudinga hollowtube.A mouldis placedroundthe hot

tube,knownas a parison,and closedup on it. The mouldsealsthe lowerend

of the tubeand the top end is cut off with a [Link] mouldthen moveson to

haveair injectedintothe [Link] air causesthe still hot parisonto fill the

cold mouldwhereit hardensbeforebeingejectedwhenthe mouldis opened.

The entireprocessis automated

and is capableof highproduction

speeds.

Knife

(b )

Blow moulding

Calendering

This processis usedfor the productionof continuouslengthsof sheet

thermoplastic

mategials.

The calenderconsistsof essentially

threeor more

(,x^r7/e : rrlouso&se Ffist;"

[Link] heatedpolymerpassesbetweenand roundrollersto

emergeas an outputof [Link] processis continuous.

Forming

Edges

clorhped

Heotcd shcet

olly

--4:':

Moutd

Air

withdro*n

Vacuumforming

Formingprocessesare secondaryprocessesin that theyare usedto form

[Link] heatedsheetis pressedintoor arounda

[Link] diagramaboveillustrates

one formof this process,thisversion

beingknownas vacuumformingin that a reductionin air pressurebetween

the sheetand the mouldis usedto causethe sheetto adoptthe shapeof the

mould.

Thermoforming

can havea reasonable

outputrate,but dimensional

accuracy

good

is nottoo

and holesand threadsare not [Link] methodcan be

usedwithvery largesheetsand is usedfor formingmachinehousings,

pallets,car bodies,dinghyhulls,andsmallitemssuchas drinkingcupsfor

vendingmachines,egg cartonsand [Link] mouldsmaybe

madeout of wood,metalor [Link] be relativelycheap.

Machining

In the production

of manyproducts,

machining

can be avoidedby a careful

designand choiceof the manufacturing

[Link]

machiningprocessescan be usedwith polymersbut thereare someproblems

associatedwiththe factsthat polymersare poorheatconductorsarid have

low meltingor degradation

temperatures.

Becauseof the poorheatconduction,

littleof the heatdevelopedduringthe

machiningoperationis conductedawaythroughthe [Link] tool

usedtendsto run very [Link] polymer,if a thermoplastic,

tendsto

soften,swelland [Link] yet morefrictionand

heatdevelopment,

as well as [Link],in machiningpolymers,

correctmachining

conditions

arevital.

{esist

durro*n)nl

h""t

----* l',""*

, Tlrr^"fl*,nric-----?.1.^'3* b

/l

l0K.

IS

zxerti^ "\ \.-<-.

J

L^, *)*^'

! "---

/,,J

c"QJ

yeerstanr.

CaJe

* ^l

]^l,u'

ts

\+ J,[Link]"t

Ysrs{ctxt.

7i;'i!*ii'

Cv c . * t f . o t ,

Lo,^u"u{-";J3'

.:K

MAl001EnqineerinqPractice1

Propertiesof materials.

The principalproperties

of materials

thatare of importance

to the engineerare

as foffows

.

--(J4

( ^%')

Tensitestrength

\%

f,

Thisis the abilityof a materialto withstand

tdnsile(stretching)

loads

withoutbreaking.

Thediagrambelowshowsa heavyloadbeingheldup by a

rodfastenedto a [Link] loadis tryingto stretchthe [Link]

rod is saidto be in tension,so the materialfrom

whichthe rod is made

needsto havesufficient

tensilestrengthto resistthe pullof the load.

Fixedbeam

Rod is being stretched

by the load

Compressive strength

Thisis the abilityof a materialto withstandcompressive

(squeezing)

loads

withoutbeingcrushedor [Link] component

beingcompressed

by a [Link]

the component

needsto be

madefroma materlalwithadequatecompressive

strengthto resistthe load.

Floor

Component

is beingsgueshed

by the load

Shearsfre ngth( *t'"- &itt- |l'*L')

Thisis the abilityof a materialto withstandoffsetloads,or transverse

cutting(shearing

actions).

Load

Load

.Jo

,.JO

The diagramshowsa rivetjoiningtwo [Link]

on the two barsaretryingto separatethemby pullingone bar relativeto the

[Link] loadsare notexactlyin line,theyare saidto be offset,and

therefore,

the loadon the rivetis calleda shearingload,thatis,the rivetis

saidto be in [Link] the rivetmaterialdoesnot havesufficient

shearstrength

to resistthe loads,the rivetwill break(shearoff),andthe barsandthe loads

actingon [Link] sameeffectcan be causedby loads

pushingon the endsof the two metalbarsjoinedby the rivet.

ls

fL.*-",r"l

Jfut

Toughness (impact resistance)

Thisis the abilityof a materialto [Link] a materialshattersit is

brittle([Link]).Rubbersand mostplasticmaterials

do notshatter,

[Link]

shouldnot be confusedwithstrength.

&{5

\^""\""u"

toyhness

Hammer

Crack

Vice

c;,Jg."."".

The diagramshowsa metalrod in a vicebeingsubjected

to [Link]

the rodis madefroma pieceof [Link]

steel,for examplesilversteelin

the annealed(soft)condition

as supplied,it will haveonlya moderatetensile

strength,but underthe impactof the hammerit will bendwithoutbreaking,

thereforeit is [Link] a similarspecimenis madehardby makingit red-hot

andthencooledquicklyin water,it will nowhavea verymuchhighertensile

[Link],althoughit is nowstrongerit will proveto be brittleandwill

breakoff easilywhenstruckwitha [Link] nowlacks

toughness.

A materialis brittleand shattersbecausesmallcracksin its

grow

quicklyundera tensileforce.(Asa materialbendsits outer

surface

layerstendto stretchandare in tension.)Thereforeany materialin whichthe

spreadof surfacecracksdoesnot occuror onlyoccurstqa smallextentis

saidto be tough. @

{ot,1hn.>s cr,^...{L*Jv,,rs (/(. il,"*,-.,'

Elasticity

Thisis the abilityof a materialto deformunderloadand returnto its original

sizeand shapewhenthe loadis [Link] tensiletest

[Link] it is madefroman elasticmaterialit will be the samelength

beforeand afterthe loadis applied,despitethe factthat it will be longerwhilst

the loadis [Link] onlytruefor mostmaterials,

if the loadis

relatively

smallandwithinthe elasticrangeof the materialbeingtested.

Beloreand

afterloading

Elastlc

extension

Tensileload

applled

Plasticity

Thispropertyis the exactoppositeto elasticity.

lt is the stateof a materialthat

hasbeenloadedbeyondthe [Link] loadbeyondthatrequired

to causeelasticdeformation

the materialdeformspermanently.

lt takesa

permanent

set andwill not returnto its originalsizeand shapewhenthe load

is removed.

Whena pieceof mildsteelstripis bentat rightanglesintothe

shapeof a bracket,it showsthe propertyof plasticity

sinceit doesnotspring

[Link] shownin the [Link]

and

malleability

are particular

casesof the propertyof plasticity.

forceis applied

Strip bnt beyondth

Since plastlc flow has

elastlclimitso that

plastlcdeformation

occurs

occurredduringbendlng

stripremainsbentafter

the bendingforcahas

beenremoved

Ductility

Thisis the termusedwhenplasticdeformation

occursas the resultof

applyinga tensileload.A ductilematerialis requiredfor suchprocesses

as

wiredrawing,tubedrawing,and cold-pressing

low-carbon

steelsheetsinto

motorcarbodypanels.

Rodbeing

drawn

C ottt

l vc'r

02 oq{e$\ton

Direction

of draw

A rod beingdnwn througha

die to reduce its diameter

rcquires the property of ductilitY

r 5

'

S ..I

.d

MalleabilitY

,,!:

Li. ) v c d

(k(ttt', l\ ) J

Thisis the termusedwhenplasticdeformation

occursas the resultof

applyinga compressive

load.A malleable

materialis requiredfor such

processes

as forging,rolling,andformingrivetheads.

Forning the head of a rivet

by hantnering. Tha rlvet

necds to bc made from a

maleabla matotid to

withstand this teaunent

Hardness ( J"'" '"t)

Thisis definedas the abilityof a materialto withstandscratching

(abrasion)

or

indentation

by [Link] is an indication

of the wearresistance

of

the material.

The diagrambelowshowsa hardenedsteelballbeingpressed

firstintoa hardmaterialandthenintoa softmaterialby the [Link]

ballonlymakesa smallindentation

in the hardmaterial,

butit makesa very

muchdeeperindentation

in the [Link] oftentestedin this

mannef.

fnvrs.

f c,rtv

lhardl

'koft)

Rigidity (stiffness)

Thisis a measureof a material's

abilitynotto deflectunderan appliedload.

Forexample,althoughsteelis verymuchstrongerthancastironthe latter

materialis preferred

for machinebedsandframesbecauseit is morerigid

and lesslikelyto deflectwithconsequent

lossof alignment

and accuracy.

Cast lron

,'j

i )1

U.*.,1

rr\rcfJt

Steel

Undera lightloadcast iron

deflectslessthan steelsince

cast iron is morerigid

.M

lHeavy

I loao

la

I

Undera heavyloadthe cast

iron breakswhilstthe

strongerbut lessrigid steet

merelybendsturther

Considerthe [Link] givenloadthe castironbardeflectslessthanthe

steelbar becaugecast ironis a [Link] loadis

increased,the cast ironbarwill break,whilstthe steelbar merelydeflectsa

littlefurtherbut doesnot [Link] materialthat is rigidis not necessarily

[Link] fact,as has beenshown,the oppositeis moreoftentrue sincerigid

materialsare oftenbrittle.

MA1001EnqineerinqPractice1

Materialstesting (destructive)

Tensiletest

Strengthis definedas the abilityof a materialto resistappliedforceswithout

yieldingor [Link] conventionstrengthusuallydenotesthe resistanceof

this is the principle

a materialto a tensileloadappliedaxiallyto a specimen;

of the tensiletest.

it.::

::.,

,r.i.j,.,i,,:

tr.

i..:

i-:i,

i .

'ri,...+:1,,

i Sr1..'

compression,

Thismachineis capableof performing

shearand bendingtests

as well as [Link] carefullycontrolledtensile

extensionof that

loadto a standardspecimenand measurethe corresponding

specimen.

The diagramoverleafshowssomestandardspecimensand the directionof

are baseduponBritishStandardBS 18.

the [Link]

For the test resultsto be consistentfor any givenmaterial,it is mostimportant

that the standarddimensionsand profilesare adheredto.

3pez0t*cn

,tJ"i

rJ-

rr

(al

tdt

Apptodooa-l__-H

l_

Apptid

losd

Tensiletest specimens;(a) tumed specimenfor wedgegips, (b) sheet

specimenfor wedgegrips,(c) sheetspecimenfor pin-jointgrips,(d) tumed

specimenwith screwedends.

The gaugelength(Lo)is the lengthoverwhichthe elongationof the specimen

is [Link] minimumparallellength(L) is the minimumlengthover

whichthe specimenmustmaintaina constantcross-sectional

areabeforethe

test loadis [Link] lengthsLo,l*, L1,?rd the cross-sectional

area(A)

are all specifiedin BS 18.

Proportionsfor tensilefesfpr'eces;(a) cylindricaltestpiece,(b) flat testpiece

( r"t\'l'

cE,L,''', '>teel

(",u

3t'=!)

i '5 .rtJ)

Tensitefesfresults ( Qo* 62"^'to', n"""(

The loadappliedto the specimenand the corresponding

extensionare plotted

in the formof a graphas shownbelow;

t6

.J

E*tn'ton

(a)

Froma to b the extensionis proportional

to the appliedload.

(b)

Fromb to c it can be seenfiom the graphthatthe metalsuddenly

extendswith no increasein [Link] metalhas gonepastits elastic

limitand has reachedit'[Link] designerworksbelow

this figureto allowfor a 'factorof safety'.

(c)

Fromc to d extensionis no longerproportional

to the loadand if the

loadis removedlittleor no springbackwill [Link]

relativelygreaterloadsthe materialis showingplasticproperties.

(d)

The pointd is refenedto as the'ultimatetensilestrength'whenreferred

graphsor the'ultimatetensilestress'(UTS)when

to load/extension

[Link] usefulfigurefor comparing

refenedto stress/strain

the relativestrengthsof materials,it has littlepracticalvaluesince

engineeringequipmentis not usuallydesignedto operateso nearto

the breakingpoint.

(e)

From dto e the specimenappearsto be stretchingunderreducedload

[Link] fact the specimenis neckingso that the'load per unit

area'or stressis actuallyincreasing.

The specimenfinallywork

hardensto suchan extentthat it breaksat e. In practice,valuesof load

and extensionare of limiteduse sincetheyapplyonlyto one particular

size of specirnenand it is moreusualto plotthe stress/strain

curve.

Stressand strainare calculatedas follows:

Sfress = loailarea of cross secfion

Strain= extension/originallength

$tfol-n.

\_ 2 )"

t -t . * )-e --r; : * '

.3 ,-\-,1 b tu

2r.I

5<*

- r't'4

Jt*

sk.. c- o\e-rnv Po.'.to[ yieil] pot't)

Proof stre"" (tt

Onlyveryductilematerialssuchas fullyannealedmildsteelshowa clearly

proof stressis usedinstead.

[Link]

Proofstressis definedas the stressthat producesa specifiedamountof

plasticstrain,suchas 0.1 or 0.2percent.

f---

0 .1%

f-

proof

I

stress VietO

:/t

AT

tl

I

I

I

I

-'IT

t-

-l

I

[Link]"

istrain

(Rastic)strain

afterfracfure,c,

in

The diagramshowsa typicalstress/straincurvefor a materialof relativelytow

ductility,suchas a hardenedandtemperedmediumcarbonsteel.

Young's modulusof elasticity

The physicistRobertHookfoundthatwithinits elasticrangethe strain

producedin a materialis proportionalto

the [Link] was leftto

ThomasYoungto quantiffthis law in termsof a mathematical

constantfor

anygivenmaterial.

Stressq strain

Therefore:

Stress/Strain= constant(E)

Sttessd- StYc*vr

3tvess

= r's

-.ffi-

Thisconstantterm(E) is variously

knownas'Young'smodulus',

the'modulus

of elasticity',or the 'tensilemodulus'.Thus:

(l*

E = tensileor compressivestress

strain

t-\

()

area\

I = force/oriqinalcross-sectional

length I

I changein length/original

____----rD

,J.-

AL

Lo

(::'r

tear

t"/

t.

MA1001 Enqineering Practice 1

--'t

*e" thstr*y

,i s5't,y',,;t ,'Sst.))'

f,;'N'k'vLLb'tt';'

Materiafstesting (non-destructive) L"'t'-l.-''i'-t

1) ,'if:^

'

quality

materia

,",Ourlinry

control

of

for the

testingis invaluable

Destructive

fabricationsand assemblies

testscannotcontrolthe qualityof components,

test on a casttest piece

a

tensile

[Link] instance,

mayshowthe correctyieldpoint,strength,and [Link]

cannotshowwhethera castingmadefromthe materialcontainsblowholes,

porosityand coldshuts.

For safety,weldson piperunsand pressurevesselsmustbe free from

Suchweldsmustalso

suchas porosityandslaginclusions.

discontinuities

Theyshouldshowno reductionin crosshavecorrectfusionand penetration.

sectionalareadue to lack of [Link],for safety,the forgedlight-'

alloyhingesfor the controlsurfacesof aircraftmustbe freefrom cracksdue to

or graingrowthdue to forgingat too higha

forgingat too low a temperature,

temperature.

testingcan be veryexpensive,requiring.

A full programmeof non-destructive

througheachseriesof [Link]

to be handledindividually

eachcomponent

(for

requiring

radiography)

example

complex

often

are

teststhemselves

and skilledpersonnelin theirexecution.

equipment

expensive

is not

For smallcomponentsprodueedin batchesandwhoseperformance

criticalit is sufficientto take randomsamplesfromeachbatch.

A faultyweldin the legsof an offshoreoil-rigor an under-seapipelinecould

out of all proportionto the cost of carryingout a full test

haveconsequences

of [Link],eachcriticalcomponentof an aircraftmustbe fully

mustbe

suchtestsand examinations

Obviously

inspected.

and individually

of the

and in no way affectthe propertiesand performance

non-destructive

assembly.

or

component

testingtechniquesto be consideredhereare:

The non-destructive

(a) visualexamination;

(b) visualexaminationassistedby dye-penetrants;

(c) ultrasonic

testing;

(d) eddycurrenttesting;

(e) magnetictesting;

(X-raysand gamma-rays).

(f) radiography

Visual examination

A

examination.

Thisis the simplestand cheapestpossiblenon-destructive

of a castingcan identifusuchdefectsas surfacecracks;

visualexamination

fillingof the

warpingandtwisting;and inadequate

scabs;surfaceporosity;

mould.

In the caseof welds,visualinspection

can showwhetheror notthereareany

largesurfacecracks,inadequate

fusion,lackof penetration,

insufficient

filler

joint

poor

porosity

material,

shape,surface

andundercuts.

: 'j : : : . .

]:

::'

.:

]:

[Link]

and misalignment

of the plateedges.

of the plaieedges.

WeldshowingunderCut-ind

misalignment

Useof dve penetrants

A veryold technique,

whichis stillwidelyused,is to immersethe castingin a

bathof hot [Link] paraffinreducesits viscosityso that,

combinedwith its alreadyhighsurface-tension,

it is easilydrawnintothe

finestcracksand porosityby [Link] castingis removedand

paraffin,

clean,afterwhichit is paintedwithwhitewash.

wipedthoroughly

exudingfromthe cracks,will discolourthe whitewashand revealthe presence

of surfacecracksand porosity.

A moremoderntechnique

usedfor largecastingsis to paintthemwithspecial

penetrantswhichare readilydrawnintothe surfacecracksand porosityat

roomtemperature.

The [Link]

allowingtimefor the penetrantto be absorbedintoany surfacecrackswhich

maybe present,the castingis thoroughly

cleanedoff anddustedwith a white

[Link] the powderindicatewherethe cracksare.

A moresophisticated

techniqueis to use speciallydevelopedfluorescent

penetrants.

penetrant

The

is paintedoverthe surfaceof the castingor applied

by pressureaerosolsprayin the caseof [Link]

penetration

the surpluspenetrantis cleanedoff and the castingis viewed

[Link] presenceof any penetrantexudingfromsurface

cracksand porositywill appearas glowinglinesand spotsagainsta dark

background.

Ultrasonic,testino

Soundwaveswhosefrequencyis too highto be heardby humanbeingsare

saidto be [Link] higherthe frequency(theshorterthe wavelength)

soundwaves,the easierit is to beamthemand controlthem.

of the ultrasonic

The frequenciesused

for ultrasonic

testinglie between0.5 MHzand 15 MHz

[Link]

the [Link]

between.

I MHzand 3

MHzare suitablefor steelcomponents.

Pulsesof highfrequencyoscillationsare generatedelectronically,

amplified,

and fed intosuitabletransducersfor [Link]

transducersexploitpiezoelectriceffects.

Piezoelectriceffects

Theserely uponthe fact that certaincrystalssuchas quartzchange

[Link]

dimensionally

alternatingcurrentpassesthroughthe crystal,the crystalwillchangein size in

stepwiththe alternations.

The'bleep'signal

in computers

and electronic

alarmclocksis usuallygeneratedusingpiezoelectric

devices.

An advantageof the piezoelectric

effectis that it is [Link] only can an

electriccurrentchangethe sizeof the crystal,strainingthe crystal

generates

mechanically

a corresponding

[Link] transducer

piezoelectric

using

effectscan be usedbothas an ultrasonictransmitterand

as a receiver

Transducar

fil Goodcornponont

fin Dohctlw componett

Eeflection ftorn

crack

Fcflgstion

Reflectlonfrom

rcar anrfaco .

E,tnPgrErrt

"01 Good component

lJslEt uvE componstt

rjvrllPurrrll

$1, Dcfccdw

0ll

The pulsesof highfrequencyoscillations

are drivenintothe componentby the

[Link] soundwavesmeetBnydiscontinuity,suchas a crack,

the wavesare reflectedbackinto the transducerwherethey are converted

intoelectricalpulseswhichcan be displayedon the screenof an oscilloscope.

By usingpulsesof shortduration,the sametransducercrntransmitand

[Link] distancebetweenthe incidentpulseand the

reflectionfom the backsurfaceof the componentis proportional

to the

componentthickness,the positionof the reflectionfromthe faultclearly

indicateswhereit lies in the componentrelativeto the frontand backfaces.

Eddv cunent testino

Thistechniquedependsuponthe fact that if an alternatingmagneticfieldis

linkedwith any metallicobject,eddy currentswill be inducedin the metallic

objectby electro-magnetic

[Link] all metals

whetherthey are fenomagnetic

or non-magnetic.

:-Compstnt

undd t!!t

A high-frequency

alternatingcunentis madeto flowthrougha smallcoil and,

as a result,a highfrequencyaltematingmagneticfield is set up aroundthe

[Link]

circulatein the componentand producemagneticfieldsin theirown right.

Thesesecondaryfieldsreactwiththe fieldof the inductioncoil and affectthe

flow of cunentthroughthat coil. Providingthere is no changein sectionor

composition

as the inductioncoilis movedacrossthe surfaceof the

componentthe resultantcurrentin the coilwill [Link], however,

the inductioncoil movesover a crackor otherfaultin the component,the

eddycurrentsystemwill be temporarilydisruptedand the resultantcurrentin

the coilwill [Link],if the inductioncoil is movedoverthe surface

of the componentand the resultantcurrentthroughthe coil is constantly

monitoredon the screenof an oscilloscope,

thenany cracksor other

discontinuities

in the componentwill be revealed.

Maqnetic testinq

Thismethodof crackdetection,

althoughsimpleand reliable,can onlybe

appliedto ferromagnetic

[Link],it is onlyappropriate

for surface

cracksand discontinuities

not morethan 10 mm belowthe surfaceof the

[Link] baseduponthe factthat the magnetic

susceptibility

in the regionof a discontinuity

is inferiorto that of the

surroundingmetaland that this distortsthe magneticflux distribution.

The

resultingdistortionof the flux fieldis usuallydetectedby meansof magnetic

powder(magnetic

ironoxide).The magneticpowder'bunches'in

the vicinity

of the fault as shownbelow.

Bunchingoccursat crack

Thinlyspread

magneticpowder

Component

The componentundertest maybe placedbetweenthe polesof a powerful

[Link] resultsin the magneticfieldlyingparallelto the surfaceof the

componentand is idealforlocatingfaultsat right-angles

to the flux field.

Magneticcrackdetection,likeothernon-destructive

testscan be appliedto

[Link] is effectivein showingup surfacecracksinvisibleto

the [Link] uncommonin the wire or rod fromwhich

largecoil springsare [Link]

thesecracksdo not developuntilafter

the springshavebeenwoundandheat-treated.

Consequently

coil springsfor

criticalapplications

are generallyinspectedmigneticallyaftei manuiacture.

Radioqraphv

processin whichthe'illumination'

Thisis a photographic

of the component

is

by X-raysor the even [Link]

electromagnetic

radiationsexactlythe sameas radiowavesand lightwaves,

exceptthat they havea very muchshorterwavelength(higherfrequency).

This enablesX-raysand gammaraysto [Link]

photographic

film is exposedto X-raysor gammaraysand then developed,

the film [Link] a solidobjectis placedbetweenthe sourceof

radiationand the film so that it castsa shadowon the film,the levelof

radiationreachingthe film in the shadowareawill be reducedand the shadow

will appearon the film afterdevelopment

as a lessdarkarea.

Solid obiect

G

D

sourcesare usuallyusedfor siteworkandthickermaterials.

Gamma-ray

This

is becausethe radiationsourceis moreportableand becauseit is more

penetrating.

The radiationsourceis a smallamounta radioactive

material

suchas iridium192or [Link] radioactive

materialis continuously

emittingradiationand hasto be storedin a heavy,lead-lined

container.

Provision

is madeto opena'window'in the container

remotelywhenan

(gamma-ray)

exposureis to be madeas [Link]

sources

do not givea constantoutputlikean X-raytube,but [Link]

usefullifeof iridium192is about40 days,andthatof cobalt60 is about5

years-The rateof decayis exponential,

rapidat firstand thenprogressively

[Link] dangerous

to handleoutsidetheircontainers

almostindefinitely.

isotope holdar

botope petret

lcobalt 6O o

lddlum 19ll

Lsd shoath

Stringentsafetyprecautions

and codesof practicemustbe observed

wheneverX-rayor gammaradiationis [Link] radiography

equipmentmustbe protectedby radiationresistantscreensand otherpersons

mustbe keptwell awayfromthe [Link] essential

andthe operatorshouldchangehisor herprotective

overallsregularly"

Normallythe operatorwearsa radiation-sensitive

tabwhichchangescolourif

exposedto excessiveradiationbut belowthe dangerlevelto the operator.

Further,radiographers

shouldbe subjectedto regularmedicalchecks.

Porvertransmissionsh#ting

Continuous mechanicalpower is usually transmifted along and

betweenrotating [Link] accomplishedby

gears,belts, chains or other similar means for matching the

torque/speed characteristicsof the interconnectedshafts- eg. a car

needsgearsbetween the enginesrankshaft and drive wheel hal,f-shafts.

shafu rotating only at constantspeed n (rev/s) are consideredhere,

and as shafts are usually staticaily determinate they may be examined

by the techniques of [Link], since

-power =

force ( I{) . finear velocify(m/s)in kanslational applicatioruand

-power = torque ( Nm) * angularvelocify (= 2n

n rad/s) in rotational

applications,

. . . . then it follows that torqueis a major load component in power transmitting

rotating shafts.

Torque maybe transfered to or from the end of

oneshaftby u secondcoaxialshaft- this is a pure

torque,a twist aboutthe [Link]

is accomplishedby a shaftcoupling,'

{\

\- t

which

consistsof two often identical half-couplirgs which are dabhmounted

on one of the shafu before being connectedtogether non-pergranently.

The mounting of a half-coupiing on a shaft must prevent relative

rotation when torque is applied - this is achievedby a positively

inierlocking element exemplifiedby a key (or a derivative of this such

as a spline) or by friction. Shownhere is the free body of a shaft keyed

to a coupfing half - the torque key

on the shaft is equilibrated by shalr

an equaland oppositetorque

on the [Link]

bodiesof the individual elementsclarify how the key'sfacesg,verise

to

.qoitibrating coupleon boththe shaftand the hjf-coupdg.

T

Thetypicalfriction-based

mountingbelowcomprisesa split tapered

bushwhich is forcedby screwsinto a mating tapermachinedin the

FBDofshElt

bore of the halfic-rEvnI I

[Link]

bushcontracts

onto the shaft

FBDofhalf*oupling

causinghigh

?c r t-

l+

r,ffi

You might also like

- Overview of Traditional Machining ProcessesNo ratings yetOverview of Traditional Machining Processes29 pages

- Importance of Machine Tools in ManufacturingNo ratings yetImportance of Machine Tools in Manufacturing20 pages

- Heavy Metal Machining Techniques Part 2No ratings yetHeavy Metal Machining Techniques Part 267 pages

- BMEE304P - Metal Forming and Machining Lab ManualNo ratings yetBMEE304P - Metal Forming and Machining Lab Manual30 pages

- Production Technology: Department of Mechanical EngineeringNo ratings yetProduction Technology: Department of Mechanical Engineering17 pages

- Me3382 Manufacturing Technology Laboratory 1400774932 MT Lab ManualNo ratings yetMe3382 Manufacturing Technology Laboratory 1400774932 MT Lab Manual55 pages

- Angular Velocity:: Production TechnologyNo ratings yetAngular Velocity:: Production Technology10 pages

- ME2258 Manufacturing Technology Lab IINo ratings yetME2258 Manufacturing Technology Lab II14 pages

- Milling Machine Safety and Operation GuideNo ratings yetMilling Machine Safety and Operation Guide24 pages

- Determination of Standard Data in Machining OperationsNo ratings yetDetermination of Standard Data in Machining Operations6 pages

- ME8462-Manufacturing Technology Lab-II 2017 RegulationNo ratings yetME8462-Manufacturing Technology Lab-II 2017 Regulation46 pages

- Tool Making - Edward Russell Markham, American Technical Society, American - 2008 - Anna's ArchiveNo ratings yetTool Making - Edward Russell Markham, American Technical Society, American - 2008 - Anna's Archive308 pages

- UNIT-V - Drilling and Milling (3 Files Merged)No ratings yetUNIT-V - Drilling and Milling (3 Files Merged)224 pages

- Batch 4-Manufacturing Laboratory RecordNo ratings yetBatch 4-Manufacturing Laboratory Record43 pages

- Physical Computing101: Part 3: Control of Mobile Robots: Hardware Lecture #7No ratings yetPhysical Computing101: Part 3: Control of Mobile Robots: Hardware Lecture #78 pages

- GLUE LECTURE 6 - Vectors For Naviga8on: (This Will Be Helpful For Quiz 6!)No ratings yetGLUE LECTURE 6 - Vectors For Naviga8on: (This Will Be Helpful For Quiz 6!)37 pages

- Physical Computing101: Part 2: Control of Mobile Robots: Hardware Lecture #6No ratings yetPhysical Computing101: Part 2: Control of Mobile Robots: Hardware Lecture #67 pages

- Physical Computing101: Part 1: Control of Mobile Robots: Hardware Lecture #5No ratings yetPhysical Computing101: Part 1: Control of Mobile Robots: Hardware Lecture #56 pages

- Control of Mobile Robots: Glue Lectures: InstructorNo ratings yetControl of Mobile Robots: Glue Lectures: Instructor23 pages

- Programming & Simulation Lecture 1 SlidesNo ratings yetProgramming & Simulation Lecture 1 Slides8 pages

- Plastic Extrusion Manufacturing OverviewNo ratings yetPlastic Extrusion Manufacturing Overview6 pages

- Static and Fatigue Analysis of A CylinderNo ratings yetStatic and Fatigue Analysis of A Cylinder6 pages

- Manabayeva Et Al 2023 Dry Reforming of Methane Over Ni Fe Al Catalysts Prepared by Solution Combustion SynthesisNo ratings yetManabayeva Et Al 2023 Dry Reforming of Methane Over Ni Fe Al Catalysts Prepared by Solution Combustion Synthesis17 pages

- NCERT Solutions For Class 9 Science Chapter 1 Matter in Our SurroundingsNo ratings yetNCERT Solutions For Class 9 Science Chapter 1 Matter in Our Surroundings6 pages

- Flat Slabs With Hidden Beams - FormattedNo ratings yetFlat Slabs With Hidden Beams - Formatted4 pages

- Earth Quakes: Presentation by AJA.V.P Prepared by SARATH BABU.M.G100% (1)Earth Quakes: Presentation by AJA.V.P Prepared by SARATH BABU.M.G20 pages

- RK Rajput Objective Electrical-Www - Allexamreview.com-1No ratings yetRK Rajput Objective Electrical-Www - Allexamreview.com-11,132 pages

- Bridgman-Stockbarger Technique: CrystallizationNo ratings yetBridgman-Stockbarger Technique: Crystallization2 pages

- 10.troubleshooting Method: 10-1. The Refrigerator Does Not OperateNo ratings yet10.troubleshooting Method: 10-1. The Refrigerator Does Not Operate4 pages

- PHYSICS PRACTICAL - Determination of Viscosity of Liquid.No ratings yetPHYSICS PRACTICAL - Determination of Viscosity of Liquid.7 pages

- Optical Methods in Pharmaceutical AnalysisNo ratings yetOptical Methods in Pharmaceutical Analysis71 pages

- KSB Mechanical Seals - Failure Analysis PDF100% (4)KSB Mechanical Seals - Failure Analysis PDF34 pages

- Soil Questionnaire WITH ANSWERS August 2021No ratings yetSoil Questionnaire WITH ANSWERS August 20217 pages