Order Number: MGCS050603S0

Digital Imaging Systems

DP-1515P [ Version 1.2 ]

Please file and use this supplement manual together with the DP-1520P/1820P/1820E Parts Manual, Order No. MGCS050606CO.

WARNING

This service information is designed for experienced repair technicians only and is not intended for use by the general public. It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product. Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service or repair the product or products dealt within this service information by anyone else could result in serious injury or death.

2006 Panasonic Communications Co., Ltd. All rights reserved. Unauthorized copying and distribution is a violation of law. Published in Japan.

General Annotations

1. Panasonic Digital Document Company and other Panasonic Sales Companies reserve the right to change any information enclosed herein without prior notification. (This includes, but is not limited to, parts pricing, availability, and text) 2. Electrical parts supplied may include previously used components. 3. Important Safety Notice Components identified by a mark, have special characteristics important for safety. When replacing any of these components, use only manufacturers specified parts.

4. In New Parts column, "N" indicates part is used only in DP-1515P model, "C" indicates part is used in previous models. 5. In Remarks column, "PM" indicates Preventive Maintenance Part". 6. In Remarks column, "RTL" indicates that the Retention Time is limited for this item. After the discontinuation of this assembly in production, the item will continue to be available for a specific period of time. The retention period of availability is dependant on the type of assembly, and in accordance with the laws governing part and product retention. After the end of this period, the assembly will no longer be available. 7. This Unit" which includes other itemized parts is provided as Limited Availability" for your convenience, and will only be offered for up to 3 years after the production of the unit ceases. However, the individual contents of the assembly will be available for the standard period. 8. This Product Uses Lead (Pb) Free Solder Printed Circuit Boards (PCBs). Information regarding Lead-Free (PbF) solder; Distinction of PbF PCB: PCBs (manufactured) using lead free solder will have a mark following the PCB part numbers in a label on the PCB. Caution: Pb free solder has a higher melting point than standard solder; typically the melting point is 50 - 70 F (30 - 40 C) higher. Please use a soldering iron with temperature control and adjust it to 700 20 F (370 10 C). Exercise care while using higher temperature soldering irons, do not heat the PCB for too long to prevent solder splash or damage to the PCB. Pb free solder will tend to splash when heated too high (about 1100 F/600 C). ECO SOLDER M705 (available from Senju Metal Industry Co., Ltd.; URL: http://www.senju-m.co.jp) is recommended when repairing PbF PCBs.

General Annotations

9. Important Notice (especially in those countries belonging to the European Union): This product is fully compliant with the national laws transposed from the EU Directive on the restriction of the use of certain hazardous substances (RoHS) in electrical and electronic equipment, effective 1st July 2006 in the EU countries. In order for the product to comply with the RoHS Directive, the six particular substances (lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls, and polybrominated diphenyl ethers) have been either totally eliminated or limited to the concentration level below maximum allowed. Consequently spare parts have been changed to RoHS-compliant parts where applicable. Due to spare parts application of RoHS legislation, non-compliant spare parts cannot be used to repair compliant products put on the EU market on or after 1st July 2006. Please therefore make sure to order and use RoHS-compliant spare parts listed in this manual.

The contents of this Parts Manual and the Specifications are subject to change without notice. Panasonic Communications Co., Ltd. reserves the right to make improvements in the product design without reservation and without notice. Published in Japan.

Precautions

For Your Safety

To prevent severe injury and loss of life, read this section carefully before servicing the Panasonic machine to ensure proper, and safe operation of your machine. Please ensure that the machine is installed near a wall outlet, and is easily accessible. This section explains the Warnings and Cautions used in the machine and/or this manual.

WARNING: Denotes a potential hazard that could result in serious injury or death. CAUTION: Denotes hazards that could result in minor injury or damage to the machine.

This section also explains the Warnings and Cautions used in the machine and/or this manual. These symbols are used to alert operators to a specific operating procedure that must not be performed. These symbols are used to alert operators to a specific operating procedure that must be emphasized in order to operate the machine safely.

WARNING Power and Ground Connection Cautions

Ensure that the plug connection is free of dust. In a damp environment, a contaminated connector can draw a significant amount of current that can generate heat and eventually cause fire if left unattended over an extended period of time. Always use the power cord provided with your machine. When an extension power cord is required, always use a properly rated cord. 120 V/15 A or AC 220 - 240V/10 A If you use a cord with an unspecified current rating, it may be underrated, and the machine, or plug may emit smoke, orbecome hot to the touch. Do not attempt to repair, pull, bend, chafe or otherwise damage the power cord. Do not place a heavy object on the cord. A damaged cord can cause fire or electric shocks. Never touch a power cord with wet hands. Danger of electric shock exists. If the power cord is damaged, or insulated wires are exposed, contact the authorized Panasonic dealer for a replacement. Using a damaged cord can cause fire or electric shocks. Stop operation immediately if your machine emits smoke, excessive heat, unusual noise, or abnormal smell, or if water is spilt onto the machine. These conditions can cause fire. Immediately switch Off and unplug the machine, and contact the authorized Panasonic . dealer. Do not disconnect or reconnect the machine while the power switch is in the On position. Disconnecting a live connector can cause arcing, consequently deforming the plug and cause fire. When disconnecting the machine, grasp the plug instead of the cord. Pulling on a cord forcibly can damage it, and cause fire, or an electric shock. When the machine is not used over an extended period of time, switch it Off and unplug it. If an unused machine is left connected to a power source for a long period, degraded insulation can cause electric shocks, current leakage or fire. Be sure to switch Off, and unplug the machine before accessing the interior of the machine for cleaning, maintenance or fault clearance. Access to a live machine's interior can cause an electric shock.

Once a month, unplug the machine and check the power cord for the following. If you notice any unusual condition, contact your authorized Panasonic . dealer The power cord is plugged firmly into the receptacle. The plug is not excessively heated, rusted, or bent. The plug and receptacle are free of dust. The cord is not cracked or frayed.

Operating Safeguards

Do not touch areas where these caution labels are attached to, the surface may be very hot and may cause severe burns. Do not place any liquid container such as a vase, or coffee cup on the machine. Spilt water can cause fire or shock hazard. Do not place any metal parts such as staples or clips on the machine. If metal and flammable parts get into the machine, they can short-circuit internal components, and cause fire or electric shocks. If debris (metal or liquid) gets into the machine, switch Off and unplug the machine immediately. Operating a debris-contaminated machine can cause fire or electric shock. Do not try to alter the machine configuration or modify any parts. An unauthorized modification can cause smoke or fire.

Consumable Safeguards

Never dispose of toner, toner cartridge, or a waste toner container into an open flame. Toner remaining in the cartridge/bottle can cause an explosion, burns and/or injuries. Keep button batteries/stamp out of the reach of children to prevent chocking or poisoning. If a button battery/verification stamp is swallowed accidentally, get medical treatment immediately.

Notice: California only:

This product contains a CR Coin Cell Lithium Battery which contains Perchlorate Material - special handling may apply. See www.dtsc.ca.gov/hazardouswaste/perchlorate

CAUTION Installation and Relocation Cautions

Do not place the machine near heaters or volatile, flammable, or combustible materials such as curtains that may catch fire. Do not place the machine in a hot, humid, dusty, or poorly ventilated environment. Prolonged exposure to these adverse conditions can cause fire or electric shocks. Place the machine on a level and sturdy surface that can withstand the weight of the machine. Refer to the Specifications section for the weight of the machine. If tilted, the machine may tip-over and cause injuries.

When relocating the machine, remove the toner and/or developer, and pack the machine e with proper packing materials for shipping.

When moving the machine, be sure to unplug the power cord from the outlet. If the machine is moved with the power cord attached, it can cause damage to the cord which could result in fire or electric shock.

CAUTION

Do not place a magnet near the safety switch of the machine. A magnet can activate the machine accidentally resulting in injuries. Do not use a highly flammable spray or solvent near the machine. It can cause fire. When copying a thick document, do not use excessive force to press it against the document glass. The glass may break and cause injuries. Never touch a labeled area found on or near the heat roller. You can get burnt. If a sheet of paper is wrapped around the heat roller, do not try to remove it when it is hot, to avoid injuries or burns. Switch Off the machine immediately, and wait until it cools down. Do not use conductive paper, e.g. folding paper, carbonic paper and coated paper. When a paper jam occurs, they can cause a short circuit and fire. Do not place any heavy object on the machine. An off-balance machine can tip-over or the heavy object can fall, causing damage and/or injuries. Keep the room ventilated when using the machine for an extended period of time to minimize the ozone density in the air. When copying with the document cover open, do not look directly at the exposure lamp. Direct eye exposure can cause eye fatigue or damage. Pull out paper trays slowly to prevent injuries. When removing jammed paper, make sure that no pieces of torn paper are left in the machine. A piece of paper remaining in the machine can cause fire. If a sheet of paper is wrapped around the heat roller, or when clearing a jammed paper that is difficult or impossible to see, do not try to remove it by yourself. Doing so can cause injuries or burns. Switch Off the machine immediately, and wait until it cools down. If accessing the inner components of the machine to clear misfed paper, etc., exercise care not to touch heated areas, or you may get burned.

Consumable Safeguards WARNING

Never throw a toner cartridge into an open flame. Toner remaining in the cartridge can cause an explosion and you can get burnt. Never throw toner, a waste toner container, or a toner cartridge into an open flame. It can cause an explosion and you can get burnt. Keep button batteries out of the reach of children. If a button battery is swallowed accidentally, get medical treatment immediately.

CAUTION

Never heat the OPC Drum, or scratch its surface. A heated, or scratched drum can be hazardous to your health. Do not mix new and old batteries at the same time, or batteries can burst or leak, causing fire or injuries. Be sure to use the specified type of batteries only. Ensure that batteries are installed with correct polarity. Incorrectly installed batteries can burst or leak, resulting in spillage or injuries.

Table of Contents

Exploded View & Parts List .................... 9

1.1. 1.2. 1.3. 1.4. 1.5. 1.6. 1.7. 1.8. 1.9. Destination Codes ....................................9 Cover Assembly......................................10 Scanner Unit ...........................................14 Control Panel Unit...................................16 Electrical Parts........................................18 Hopper Unit.............................................20 Drum Unit................................................22 Drive Unit ................................................24 PC Boards/Harnesses ............................26

1.10. Packing and Accessories (For China)..............................................30 1.11. Packing and Accessories (Except China) ........................................32

memo

1 Exploded View & Parts List

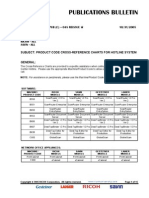

1.1. Destination Codes

Code Destination PB, PB2 Kuwait; Egypt; Bahrain; Oman PBE UK PK China Berkeley; Pakistan; Nigeria; Algeria; PM, PM2 Tunisia; Kenya; Morocco; Ghana; South Africa Code PME PP, PP2 PU, PU2 PY, PY2 PPE PS Destination Italy Russia; Ukraina; Moldova Mexico Saudi Arabia; UAE; Jordan East Euro Turky

DP-1515P

9

Ver. 1.2 SEPT 2006

1.2.

Safety Mark

Cover Assembly

Ref. No. 107 Part Number DZJE001281 PJZNF3060PB 109 PJZNF3060PK PJZNF3060PU Assembly, Document Plate N Part Name Plate, Rear Document New Parts N Remarks

DP-1515P

Destination All PB, PM, PP, PY, PS, PB2, PBE, PM2, PME, PP2, PY2, PPE PK PU, PU2

10

Ver. 1.2 SEPT 2006

DP-1515P

A B C D E

103

X2

107

106

1

110 116 117 105 104 W9 S6 114 Y3 112 102 X8 113 Y3

2

109 Y3 2832

X2 132 X2

S6 101 Y3

4

Q8

129

126 125 2841 2910 X8 Q8 131 127

128

133 Y3 124

6

2841

123

122 120 121 X8

Fig. 1 Cover Assembly (1/2)

11

Ver. 1.2 SEPT 2006

DP-1515P Safety Mark Ref. No. 201 240 New Parts N N

Part Number DZMA004795 PJKPC0043Z

Part Name Cover, Front Door Sheet Cover LAN I/F

Remarks

Destination All All

12

Ver. 1.2 SEPT 2006

DP-1515P

A B C D E

238 Y3 Y2

Y11

1

236 237 239 217 216 220 240 Q8 224 S6

2

Y2

952

3

233

S6 218 226 938 219

Y3 227 215 229 Y1 206 228 214

232

211

Y3 X8 213 209 203

6

210

204 208 207

Y3 X8 205 202 201

7

Fig. 2 Cover Assembly (2/2)

13

Ver. 1.2 SEPT 2006

1.3.

Safety Mark

Scanner Unit

Ref. No. 427 Part Number DZHP010628R PJZNF3100PK CCD Unit Part Name New Parts N Remarks

DP-1515P

Destination All

14

Ver. 1.2 SEPT 2006

DP-1515P

A B C D E

Y3 423 420

1

410

421 420 Y3 J6 421 422 308 420 Y3 408 408 417 418 420 Y3 Y3 412 419

411 426 X8 413 Y3 407 412 X8 415 414

3 2

408 308 J6 X4 427 425 406 2830 Y3 424 Y3 403 429 405 430 428

6

409 408 416

4

2811

Y3 404

2829

409

A

410 Y2

5

Y3 425 424 2834 402 404

401

Fig. 4 Scanner Unit (2/2)

15

Ver. 1.2 SEPT 2006

1.4.

Safety Mark

Control Panel Unit

Ref. No. 501 Part Number Part Name Window, Panel Cover, Panel Holder, Battery Keys, Numerical Lamp, Active Cover, Aperture Assembly, Control Panel PC Board, PNL1 PC Board, PNL2 PC Board, PNL3 New Parts N N N N N N N N N N Remarks

DP-1515P

Destination PK Except PK PK Except PK All All All All Except PK PK All All All

PJGPC0046Y PJGPC0046Z DZJE001276 502 DZJE001274 503 DZJE001275 510 DZKB000948 515 DZNA001142 537 DZJE001273 PJYPF3060PU 538 PJYPF3060PK 2904 DZEC103987R 2905 DZEC103988R 2906 DZEC103989R

16

Ver. 1.2 SEPT 2006

DP-1515P

A B C D E

501

1

538

537 539

507

2

502

S6 509 2916 2917 521

3

510 515

Q8 522 503 516

A A

X8 2923 2924 518 681 517

5

519 2905 520 X8 681 2904 2906

X8

681

7

529 530

Fig. 5 Control Panel Unit

17

Ver. 1.2 SEPT 2006

1.5.

Safety Mark

Electrical Parts

Ref. No. Part Number LPA3612F-R 829 LPA3612F-BR Depends on Destination 2802 DZEC104001R 2801 PC Board, SC PC Board, SPC N See Sect. 1.9 PC Boards All LSU Unit N Part Name New Parts Remarks

DP-1515P

Destination PB, PK, PM, PP, PU, PY, PU2 PS, PB2, PBE, PM2, PME, PP2, PY2, PPE

18

Ver. 1.2 SEPT 2006

DP-1515P

A A B B C C D D E E

X3 X3

801 801 2901 2901 680 680 Y3 Y3 802 802

1 1

Y3 Y3

X3 X3

830 830 940 940 939 939

937 937 Y3 Y3 819 819 941 941

2 2

810 810 825 825 Y4 Y4 815 815 828 828 Y3 Y3 823 823 824 824 Y4 Y4 X3 X3 829 829 2801 2801 Y3 Y3 3116 3116 806 806 Y3 Y3 Y3 Y3 813 813 812 812 Y3 Y3 814 814 808 808 Y3 Y3 807 807 818 818 Y3 Y3 X3 X3 809 809 X4 816 816 X4 3128 3128 2804 2804 Y6 Y6

Y3 Y3 820 820

3 3

826 826

Y3 Y3

4 4

681 681 803 803

5 5

Y3 Y3 806 806 Y3 Y3

6 6

3116 3116 2802 2802 681 681 817 817 Y3 Y3 680 680 2806 2806

8 8 7 7

681 681

Fig. 8 Electrical Parts

19

Ver. 1.2 SEPT 2006

1.6.

Safety Mark

Hopper Unit

Ref. No. Part Number DZJE001180 1208 DZJE001280 Holder, Rear Bottle N Part Name New Parts C Remarks

DP-1515P

Destination PBE, PME, PS (See Note) PB, PK, PM, PP, PU, PY, PPE, PB2, PK, PM2, PP2, PU2, PY2 PBE, PME, PS (See Note) PB, PK, PM, PP, PU, PY, PPE, PB2, PK, PM2, PP2, PU2, PY2 PBE, PME, PS (See Note) PB, PK, PM, PP, PU, PY, PPE, PB2, PK, PM2, PP2, PU2, PY2

DQ-TU10J-PB 1216 DQ-TUJ5K-PK Assembly, Toner Bottle

C PM (Available as Sales Item)

DZJA001422 1217 PJZYF2122PK Hopper Unit

Note: Common Part as DP-1820E/1820P/1520P.

20

Ver. 1.2 SEPT 2006

DP-1515P

A B C D E

1216

2

1208 X9 1209 1213 1212 1203 X6

5

1202

1217

1201

Fig. 12 Hopper Unit

21

Ver. 1.2 SEPT 2006

1.7.

Safety Mark

Drum Unit

Ref. No. Part Number DQ-H60J-PU 1403 DQ-HJ60K-PK 1448 PJZYF212H00 1449 PJZYF212G00 1452 PJMZC0003Z Assembly, OPC Frame Assembly, Process Unit Sheet Drum, OPC N N N N Part Name New Parts C PM (Available as Sales Item) Remarks

DP-1515P

Destination PBE, PME, PS (See Note) PB, PK, PM, PP, PU, PY, PPE, PB2, PK, PM2, PP2, PU2, PY2 All All All

Note: Common Part as DP-1820E/1820P/1520P.

22

Ver. 1.2 SEPT 2006

DP-1515P

A B C D E

1448 1436

1

1440 1438 1433 1440 1439 1455 1401 1419 1418 1454 1419 1418 1416 2837 1444 1443 1435 1428 1451 1427 1431 1432 1430 1434 1447

3 2

1437 1441 1429

1417

2807 1442 1404 1402 1405 2836

1420

1450

1452

1421 1426 1409 1425 X9 1445

6

1412 1403

1415 1411 1408 1410

1414

1424 1407 X3 1422

1412 1413 X3

1414

1449

8

Fig. 14 Drum Unit

23

Ver. 1.2 SEPT 2006

1.8.

Safety Mark

Drive Unit

Ref. No. Part Number DZLN000007 1535 PJDIC0014Z Joint, OPC N Part Name New Parts C Remarks

DP-1515P

Destination PBE, PME, PS (See Note) PB, PK, PM, PP, PU, PY, PPE, PB2, PK, PM2, PP2, PU2, PY2 PBE, PME, PS (See Note) PB, PK, PM, PP, PU, PY, PPE, PB2, PK, PM2, PP2, PU2, PY2

DZTY000311 1540 PJZWF3060PK Assembly, Main Drive

Note: Common Part as DP-1820E/1820P/1520P.

24

Ver. 1.2 SEPT 2006

DP-1515P

A B C D E

131 2822 1540 1511 1504 Y3 1518 1544 Y9 1522 1523 1555 1524 1528 1514 1548 1538 1553 J8 1549 1534 1551 1533 1537 1536 1546 1535 1547 1531 1532 1550 Y3 1542

6

1505 1506 1507

2822

1

X8 X8

1509 1501 1517 1539 1510 1506 2822 1508

1503

1502

3

1503 1525 Y3 1529 1525 1524

4

1527

1530 1515 1526 1519 1516 1521 1520 X8

5

1552 K5

680 681 680 1545

7

Y3 1513 1541 Y3 1554

Y3 934

8

Fig. 15 Drive Unit

25

Ver. 1.2 SEPT 2006

1.9.

Safety Mark

PC Boards/Harnesses

Ref. No. Part Number Part Name New Parts Remarks

DP-1515P

Destination PU, PU2 PB, PY, PB2, PBE, PY2

PJWPF3060PU DZEC103997R PJWPF3060PB DZEC103998R PJWPF3060PP 2801 DZEC103999R PJWPF3060PK DZEC104000R PJWPF3060PM DZEC104010R PJWPF3060PS 2802 DZEC104001R 2814 DZFP002105

PC Board, SC

PP, PP2, PPE PK PM, PM2, PME PS All PS, PP2, PPE, PB2, PBE, PM2, PME, PY2 PS, PP2, PPE, PB2, PBE, PM2, PME, PY2

PC Board, SPC Harness, LSU 2

N N

2826 DZFP002104

Harness, LSU 1

26

Ver. 1.2 SEPT 2006

DP-1515P

A B C D E

2810

2811 SC ( 2801 )

CN52

CN55

ADF (2846)

CN53

2816

2848

2827

CN51 CN66 CN57 CN22 CN21 CN30 CN25 CN28 CN29 CN27

2815 2843 2814 2851 2850

2849

SPC ( 2802 ) 2829

CN656 CN655 CN720

2849

4

2817

CN657 CN721

2818 2819 2831

2828

RLB (2804)

CN173

2827

CN650

CN719 CN709 CN723

5

CN171

2820 2818 2821 2821 2822 2820

CN172

2830

2833

2861 2815 2816

CN726

CN703

CN712 CN715

CN717

CN722

CN727

2826

CN701 CN707 CN706 CN702 CN708

2825

3138

2815

2823

Fig. 28 PC Boards/Harnesses (1/2)

27

Ver. 1.2 SEPT 2006

DP-1515P Safety Mark Ref. Part Number No. 2904 DZEC103987R 2905 DZEC103988R 2906 DZEC103989R New Parts N N N

Part Name PC Board, PNL1 PC Board, PNL2 PC Board, PNL3

Remarks

Destination All All All

28

Ver. 1.2 SEPT 2006

DP-1515P

A B C D E

PS (2901) 2911 2912

1

CN502 CN504

2912

CN501

2815

CN500

2

CN11 CN12 CN10

2815

2815

CN1 CN5 CN2

2815

3

2913 2833

CN3

2914

4

2925 PNL2 ( 2905 ) PNL1 ( 2904 ) 2810 519

CN220 CN234

2923

2924

2916

CN223

CN232

CN230

CN233

CN231

2923 PNL3 ( 2906 ) 2916

7

2917

2924

2917

CN253

CN252

Fig. 29 PC Boards/Harnesses (2/2)

29

Ver. 1.2 SEPT 2006

1.10. Packing and Accessories (For China)

Safety Mark Ref. Part Number No. 3405 PJPGC0392Z 3409 PJQRC0111Z 3418 PJQMC0475Z 3422 PJQXC0069Z Part Name Box Installation Instructions Operating Instructions Sheet, Appendix New Parts N N N N Remarks PK PK PK PK

DP-1515P

Destination

30

Ver. 1.2 SEPT 2006

DP-1515P

A B C D E

3417 3421 3402

3405

3409 3418 3422

3420

3411

3411

4

3406 3411 3411 3419

5

3412

3413

3419

3414

Fig. 34 Packing and Accessories

31

Ver. 1.2 SEPT 2006

1.11. Packing and Accessories (Except China)

Safety Mark Ref. No. Part Number Part Name New Parts Remarks

DP-1515P

Destination PB, PM, PP, PY, PS, PB2, PBE, PM2, PME, PP2, PY2, PPE PU, PU2 PB, PM, PP, PU, PY, PS, PB2, PBE, PM2, PME, PP2, PU2, PY2, PPE PB, PY, PB2, PY2 PB, PM, PY, PB2, PBE, PM2, PY2, PPE PU, PU2 PP, PP2 PME PS PB, PM, PP, PU, PY, PS, PB2, PBE, PM2, PME, PP2, PU2, PY2, PPE

3405

PJPGC0391Z PJPGC0393Z

Box

3409 PJQRC0112Z

Installation Instructions

3410 PJQQC0050Z PJQMC0473Z 3418 PJQMC0474Z PJQMC0476Z PJQMC0688Z PJQMC0689Z

Quick Guide

Operating Instructions

3422 PJQXC0069Z

Sheet, Appendix

32

Ver. 1.2 SEPT 2006

DP-1515P

A B C D E

3417 3421

3409 3410 3418 3422

3420

3411 3405

4

3406 3411 3411 3412

5

3411 3413

3414

Fig. 34 Packing and Accessories

33

Ver. 1.2 SEPT 2006

DZZSM00319